Embed presentation

Download to read offline

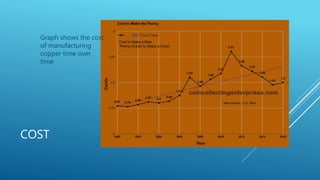

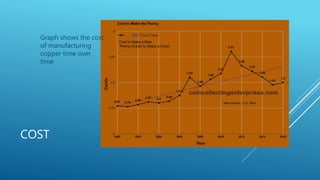

The document outlines the process of manufacturing copper coins which involves molding and engraving a master hub, creating working dies, punching coin blanks, annealing and pickling the blanks, sorting and striking the coins using the dies, and finally inspecting, counting, and packaging the coins. It also discusses the cost of manufacturing copper coins over time and notes properties of copper coins such as corrosion resistance, ability to form alloys easily, being hygienic, and having an attractive color.