The manufacturing process of a piston involves several steps:

1. Casting involves pouring molten aluminum alloy into a die to form the piston shape.

2. Heat treatment is used to alter the physical and mechanical properties of the piston.

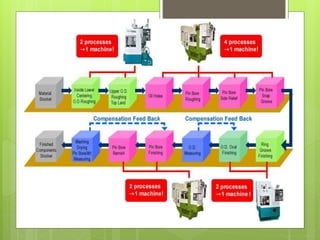

3. Machining processes like turning, drilling, grinding, and reaming are used to shape and finish the piston to the required specifications.

4. Final steps include deburring, applying a tin coating, fitting the piston pin, and final inspection before shipping.