Embed presentation

Download to read offline

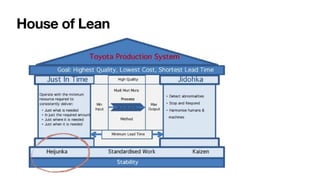

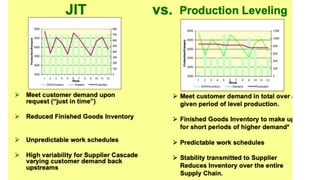

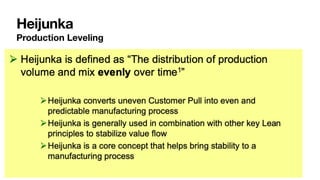

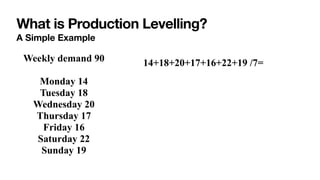

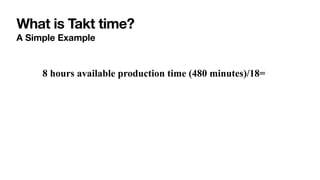

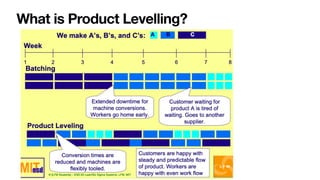

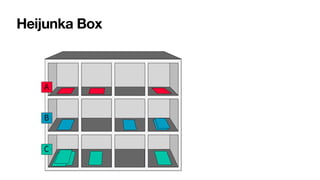

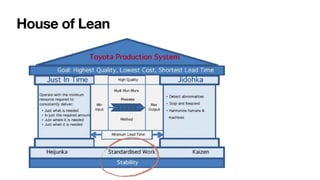

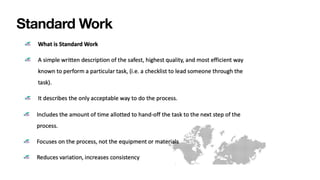

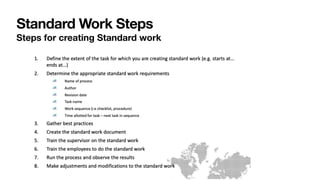

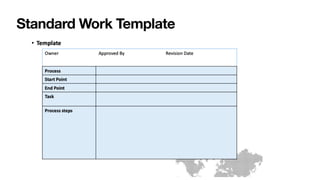

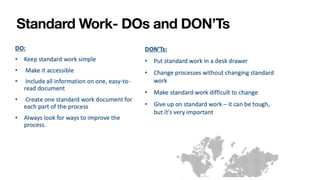

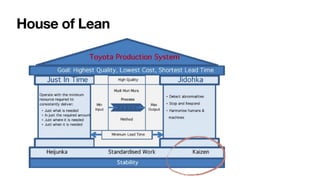

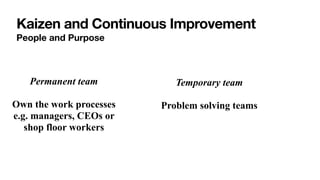

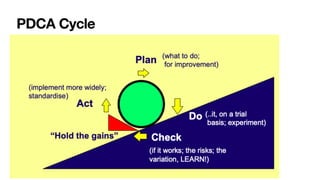

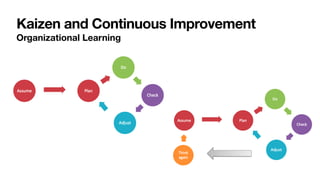

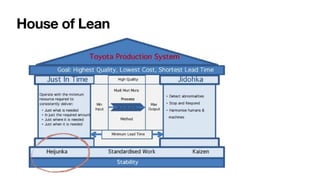

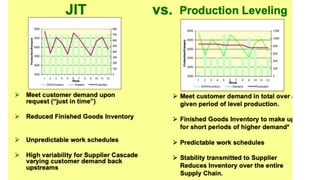

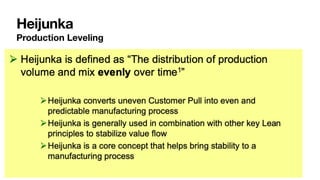

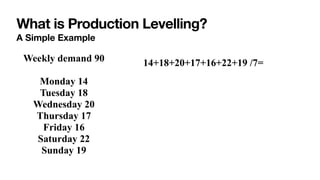

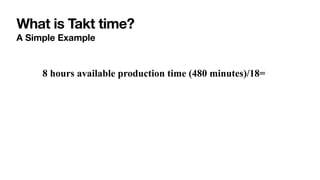

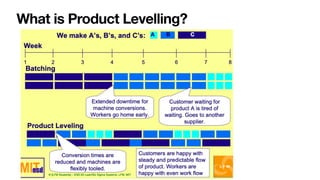

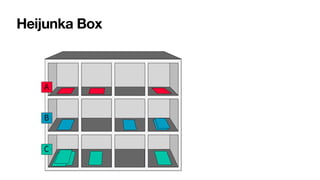

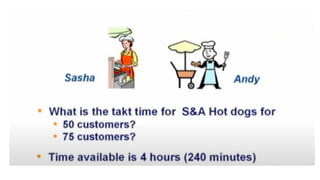

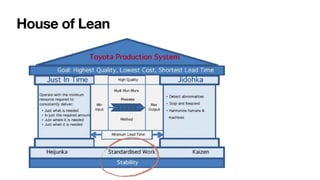

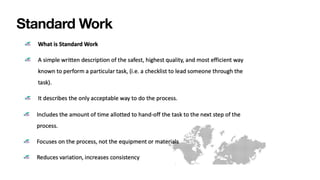

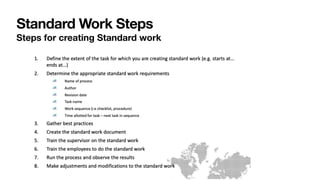

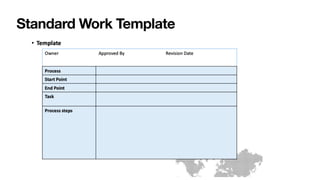

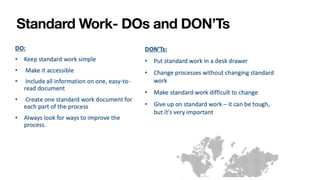

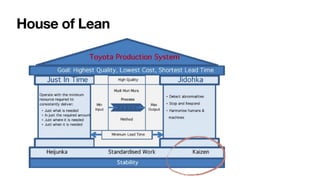

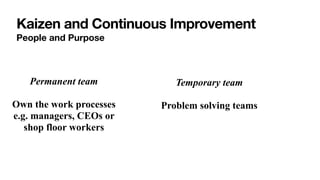

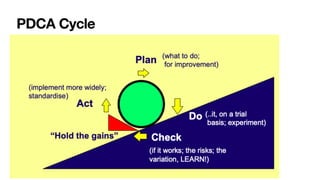

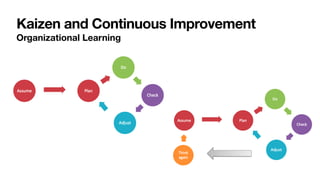

This document discusses concepts related to production leveling including Heijunka, standard work, and continuous improvement. Heijunka involves leveling production to evenly distribute workload and demand across each day to maximize efficiency. Standard work establishes consistent processes and templates. Continuous improvement, also called Kaizen, relies on permanent and temporary teams identifying areas for improvement through reflection meetings and applying the PDCA cycle for organizational learning.