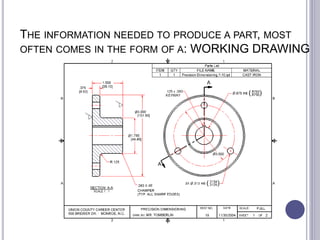

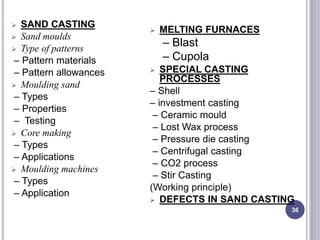

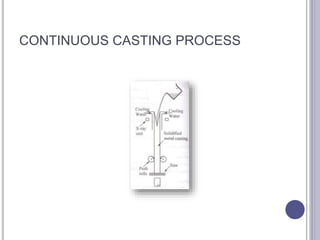

The document provides an overview of the Manufacturing Processes - UMECOO2 course which introduces various metal casting and forming processes used in manufacturing industries. It outlines the course objectives, syllabus covering topics such as metal casting, fabrication, forming and sheet metal processes. It also lists experiments and references for the course.