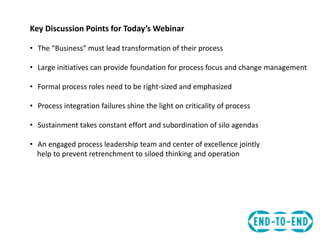

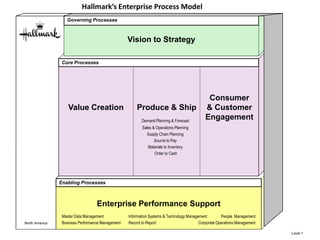

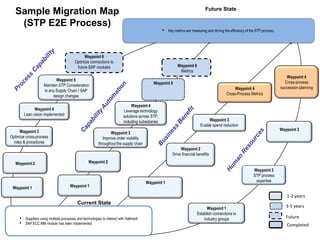

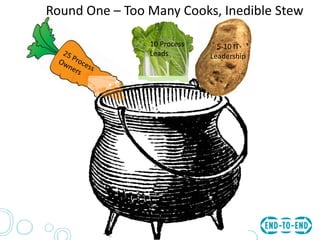

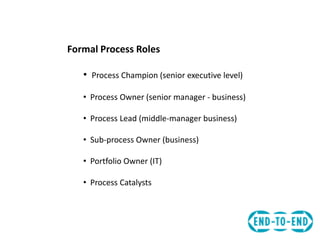

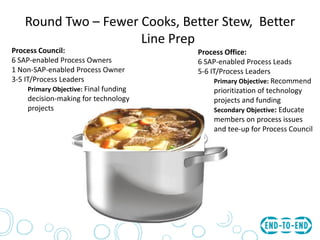

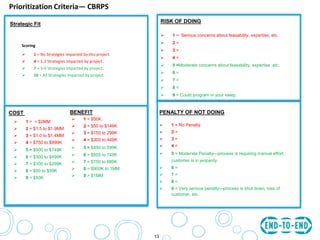

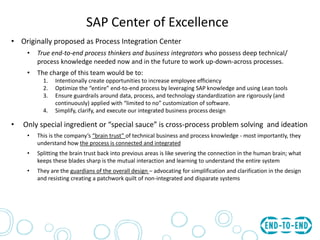

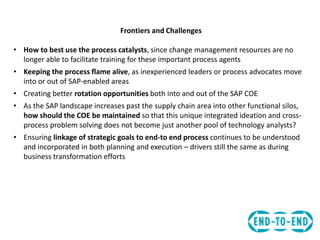

The document outlines Hallmark's approach to process transformation, emphasizing the need for business leadership in driving change and the importance of integrating processes to improve efficiency. Key initiatives include the establishment of a Center of Excellence for continuous improvement and effective resource allocation to optimize end-to-end processes using SAP technology. Challenges discussed involve maintaining cross-process collaboration and ensuring that strategic goals are consistently linked to operational execution.