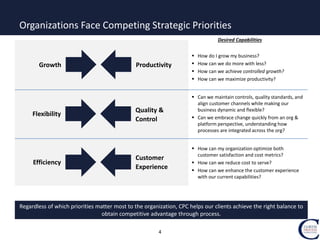

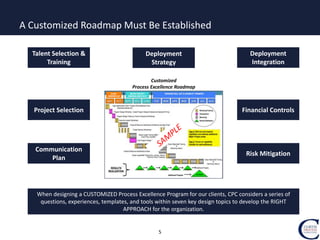

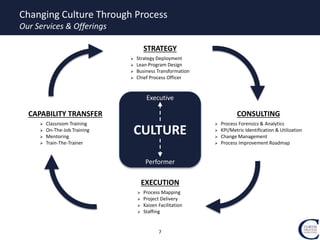

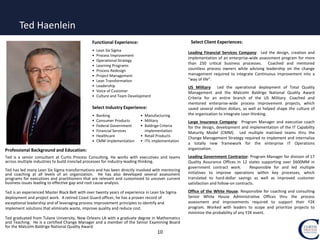

The document introduces Curtis Process Consulting, a firm dedicated to understanding and improving processes. It discusses how the firm was founded to help organizations that struggle with defining and improving their processes. The firm's consultants have extensive experience applying process improvement techniques across many industries. Curtis Process Consulting works to establish trusting partnerships with clients and develop customized approaches to address their process challenges and gain a competitive advantage.