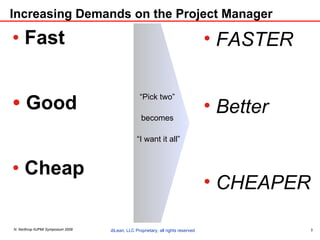

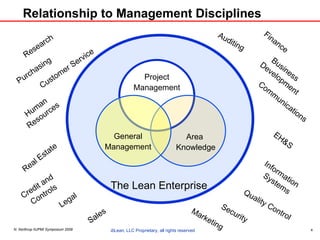

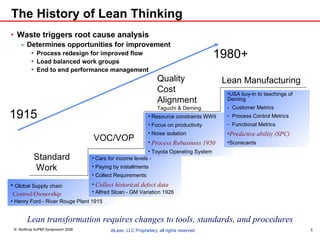

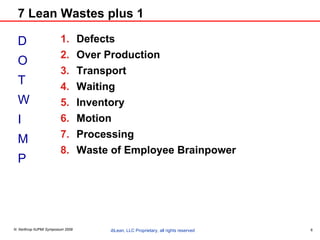

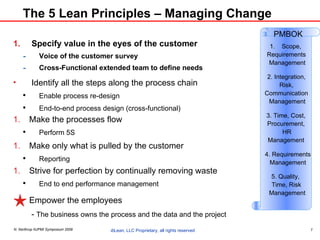

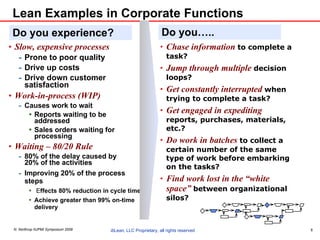

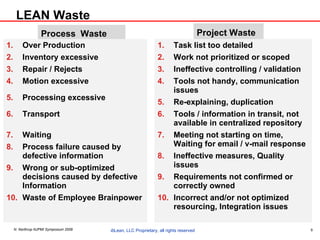

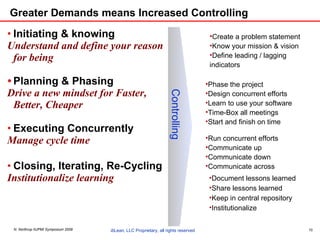

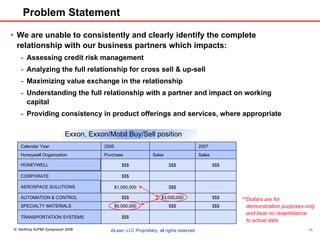

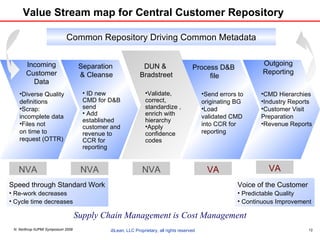

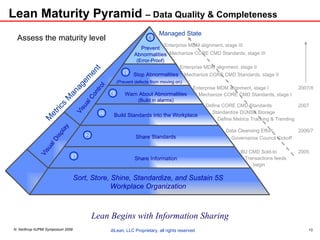

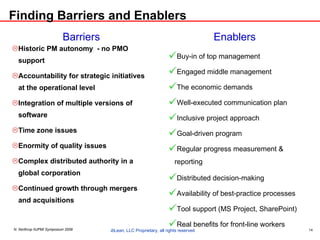

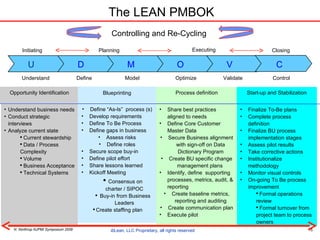

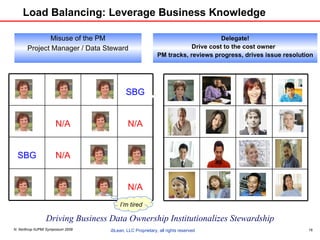

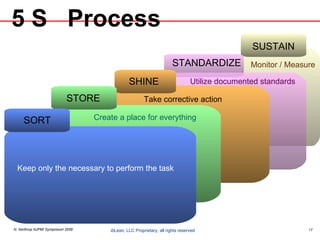

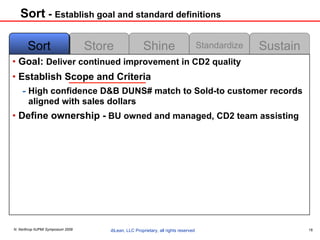

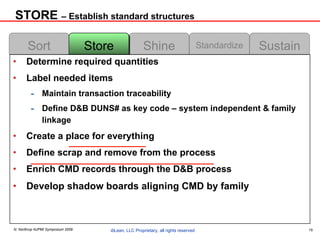

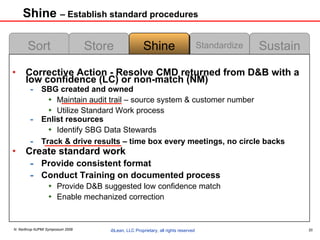

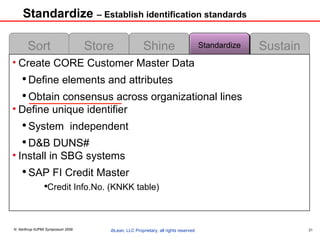

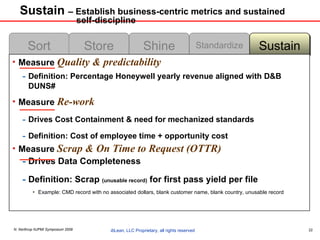

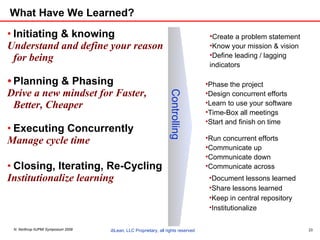

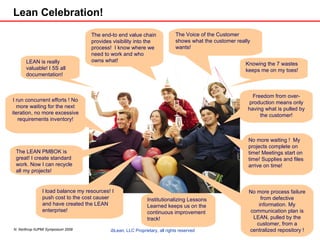

Nancy W. Northrup presented at the PMI NJ International Project Management Day on November 5, 2009. She discussed how Lean principles can help projects be completed faster, better, and cheaper. Lean focuses on eliminating waste to improve flow and value. Northrup provided examples of applying 5S and value stream mapping to processes to standardize work and reduce waste like defects, overproduction, and waiting. She emphasized the importance of continuous improvement through metrics, visual controls, and institutionalizing lessons learned.