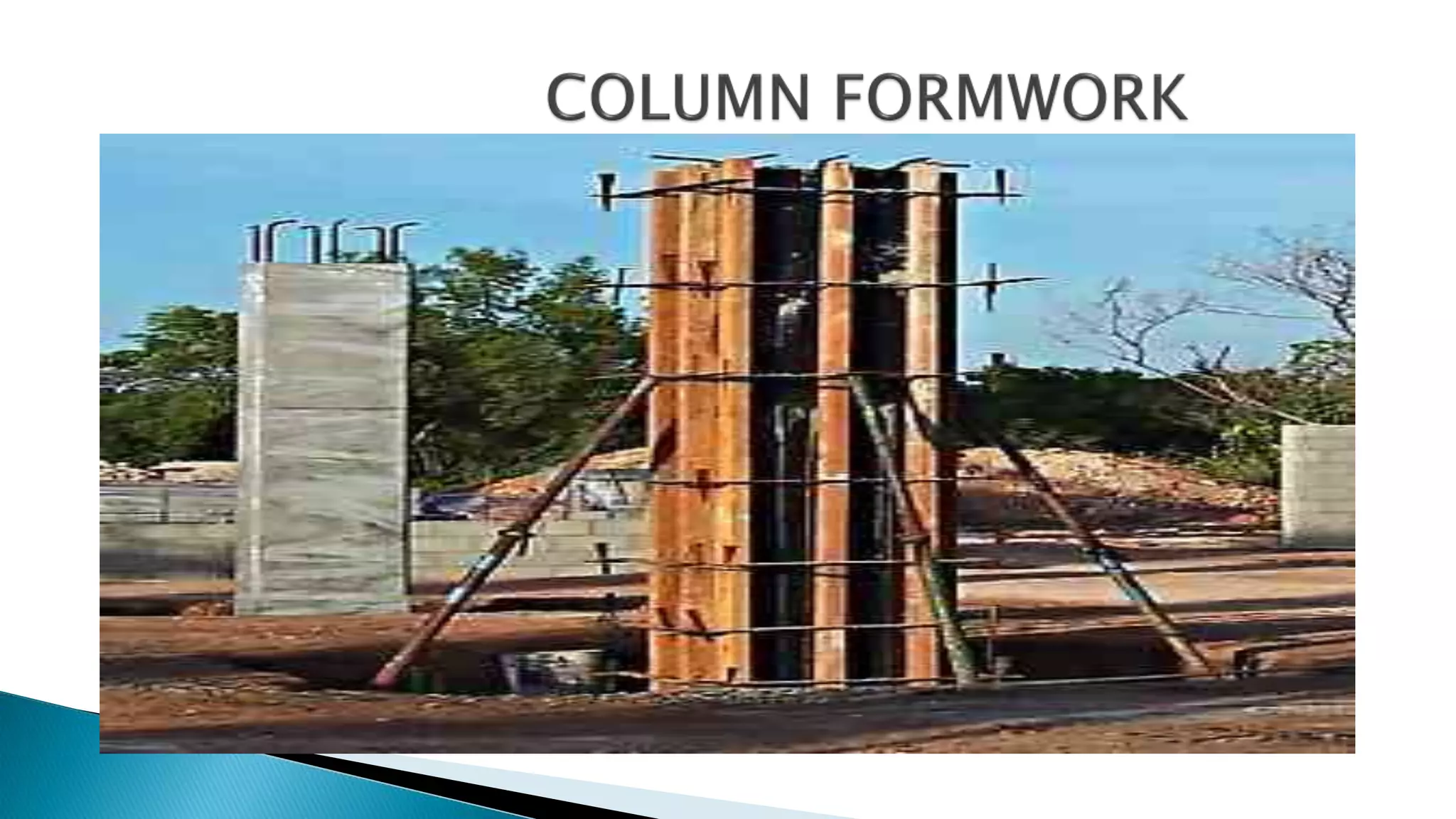

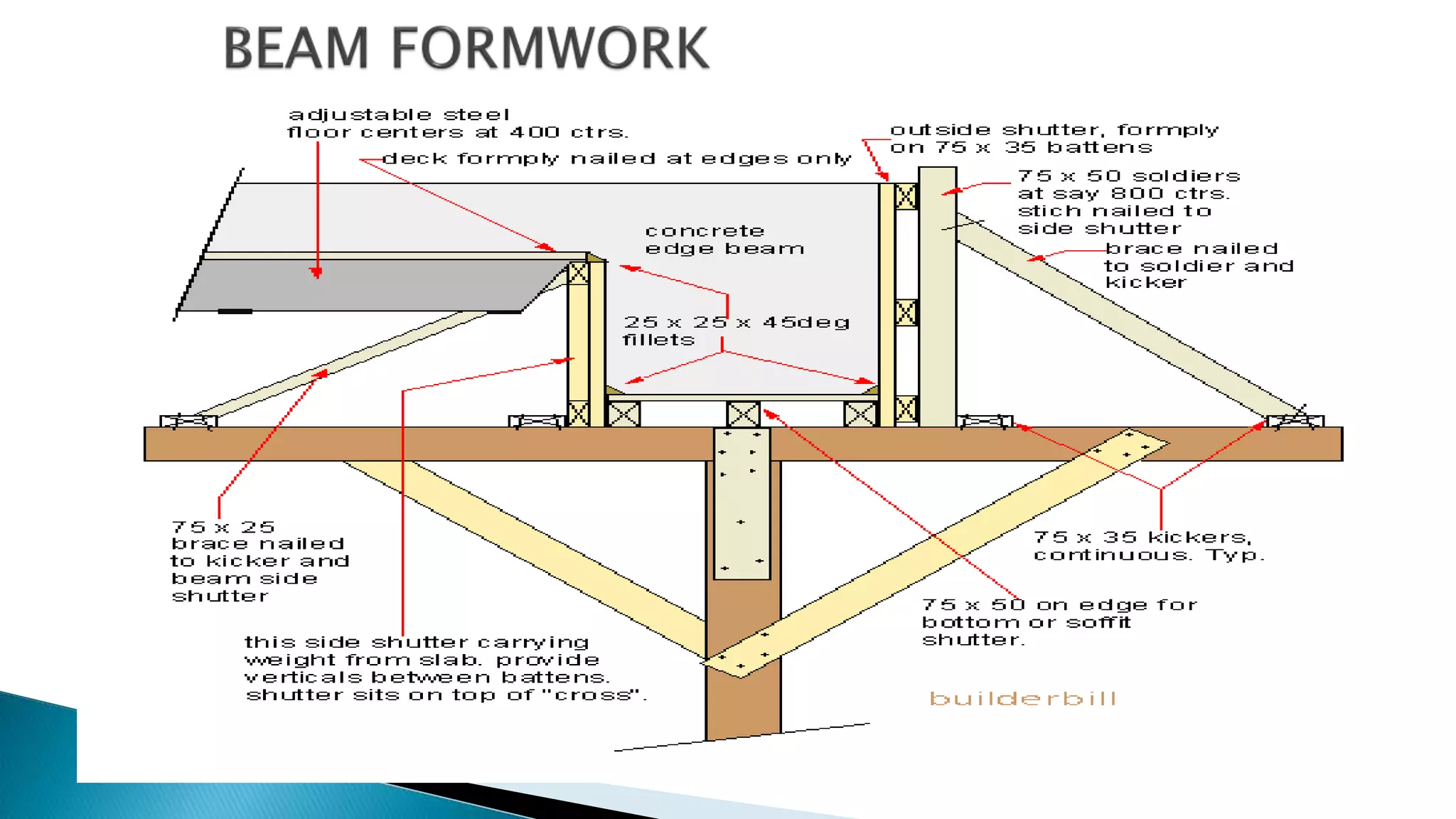

Formwork is a temporary structure used to contain wet concrete until it is cured sufficiently to stand on its own. It supports the concrete and maintains its shape. Common materials used are timber, plywood and steel. Formwork must be strong, rigid, braced and water tight. It supports live and dead loads and maintains shape during construction. Formwork is designed based on the type and location of concrete element being cast. Proper formwork design and construction is important for safety and to produce high quality concrete surfaces.