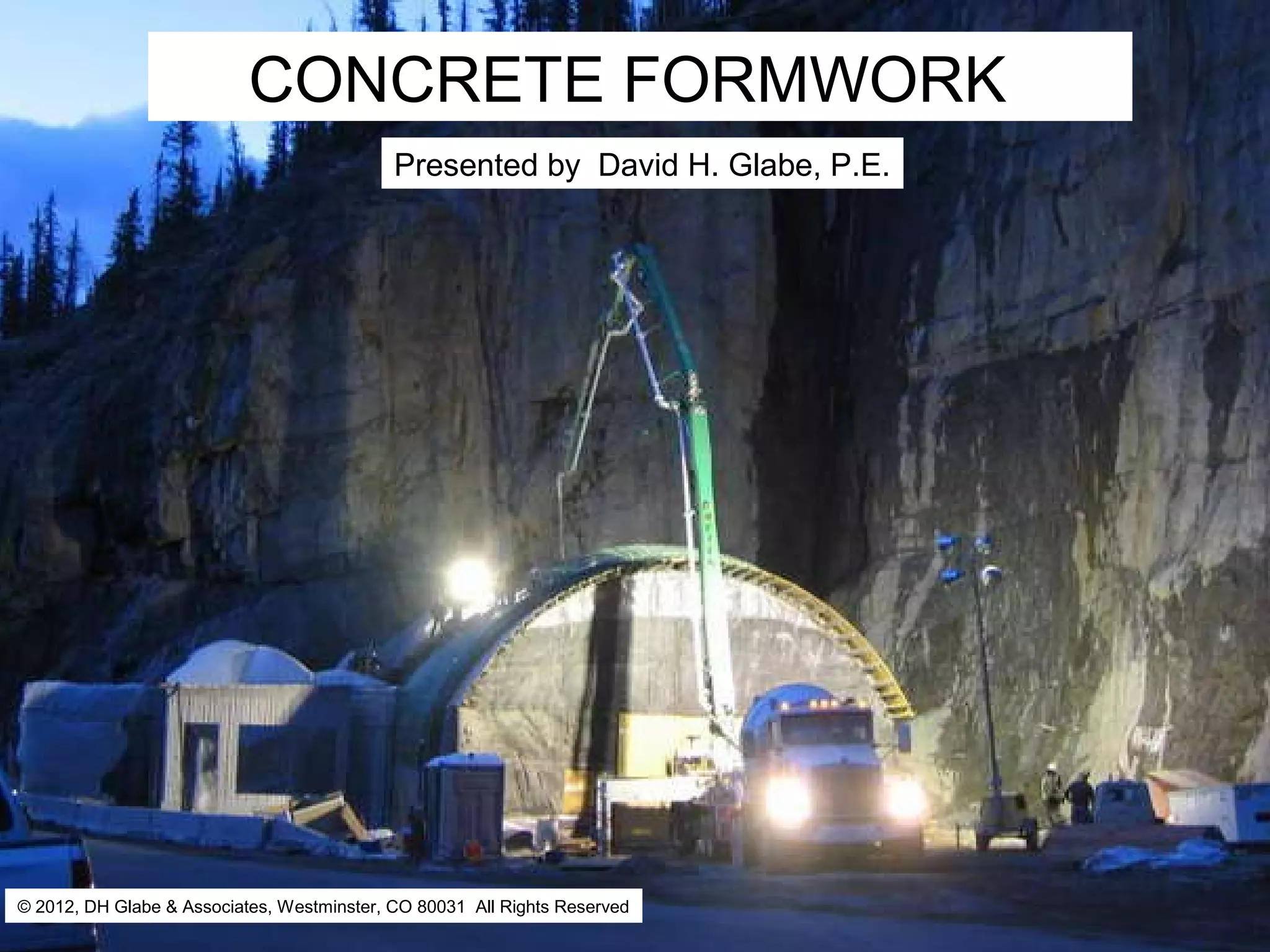

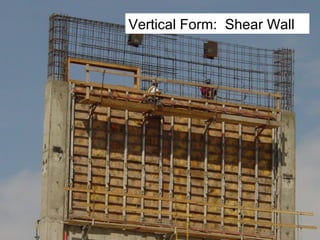

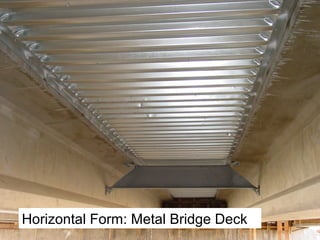

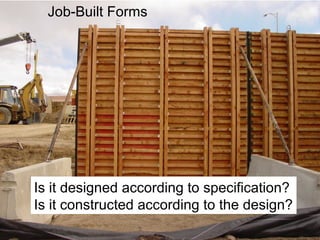

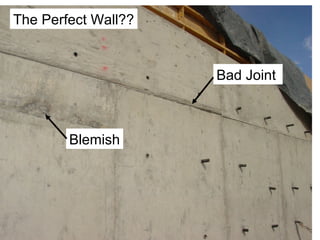

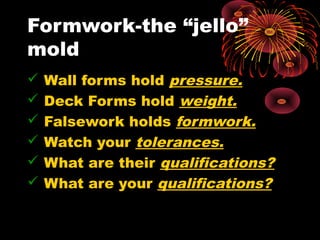

The document serves as a guide to concrete formwork, detailing its definition, types, and structural support roles. It distinguishes between formwork and falsework, clarifying their functions in retaining and supporting concrete during the curing process. Key considerations include design, materials, and successful conformance to project specifications.