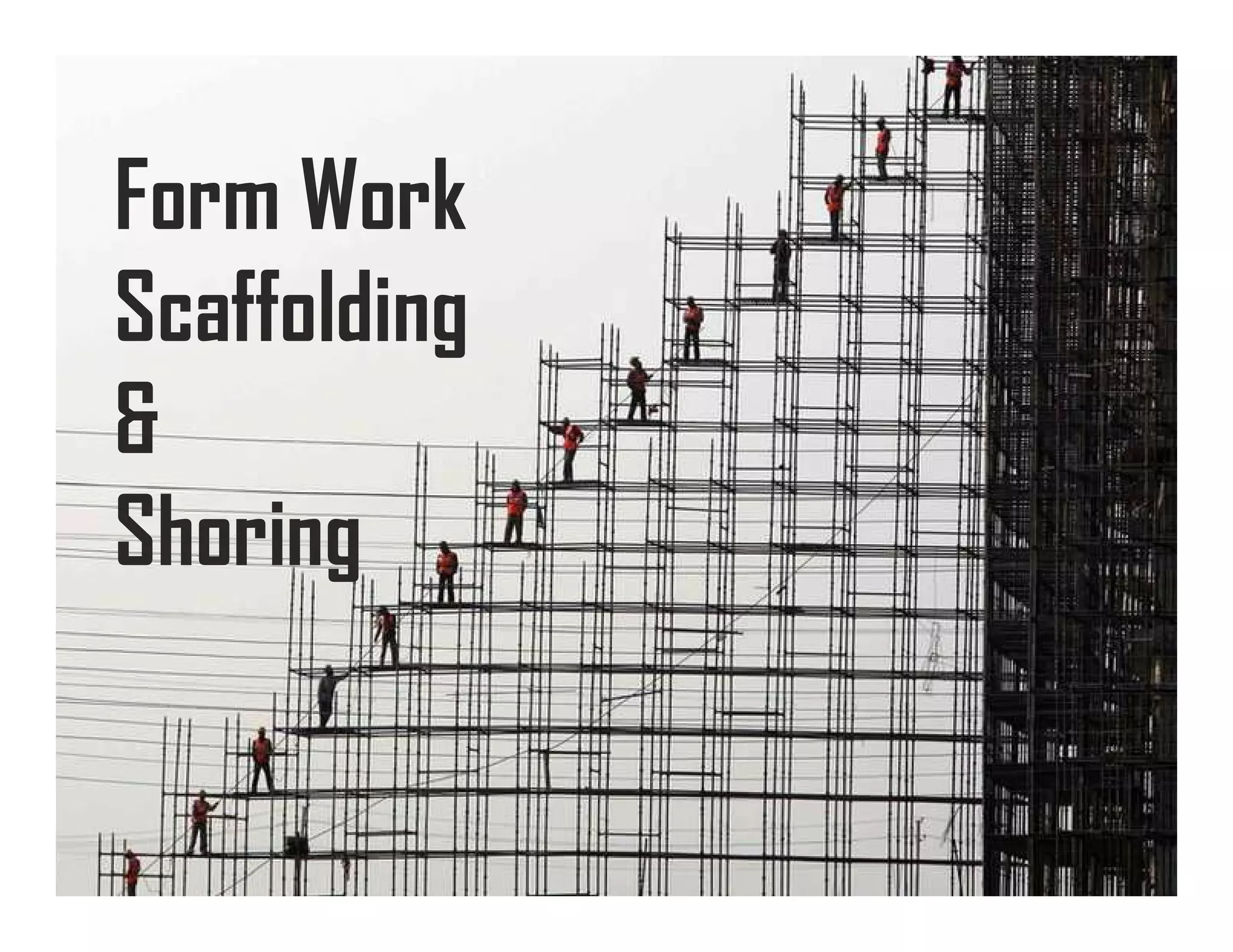

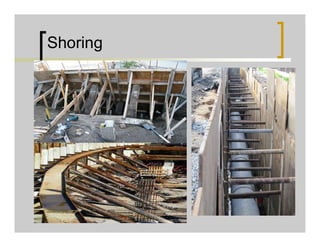

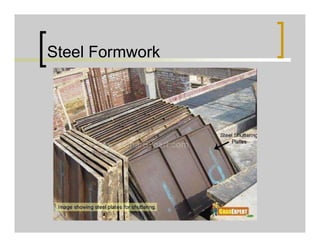

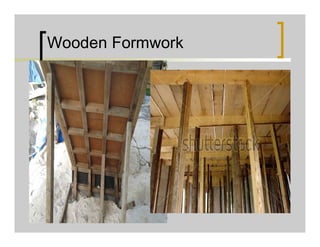

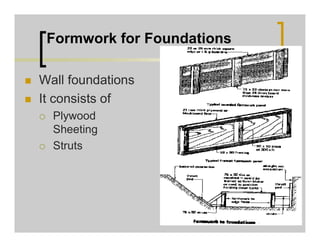

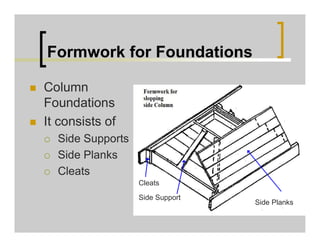

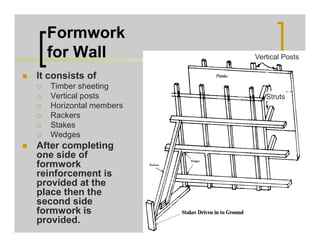

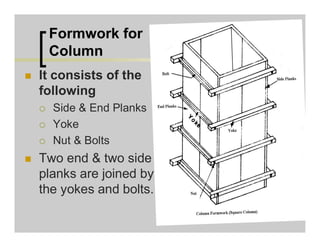

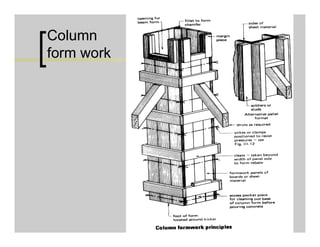

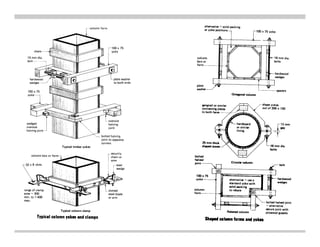

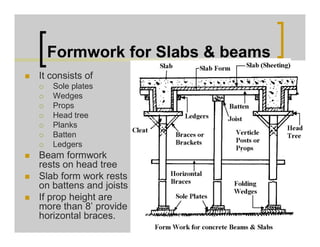

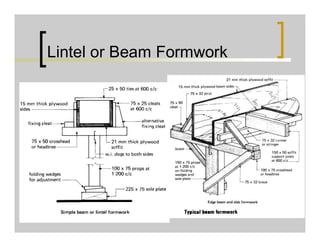

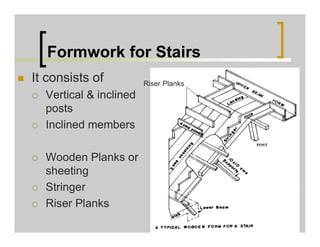

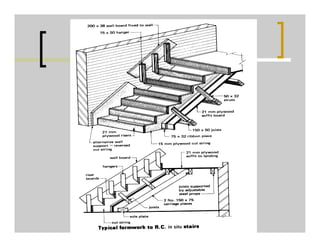

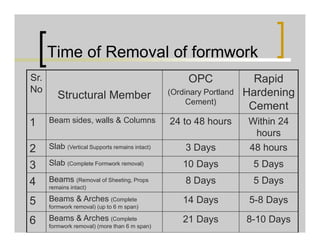

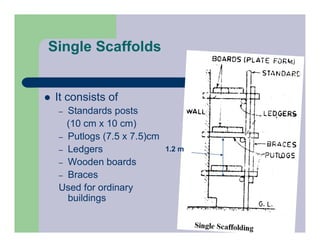

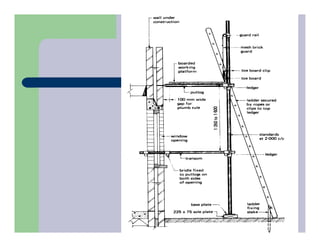

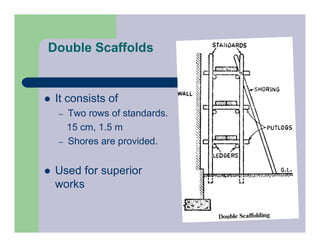

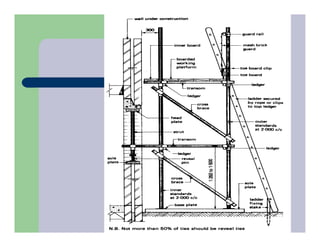

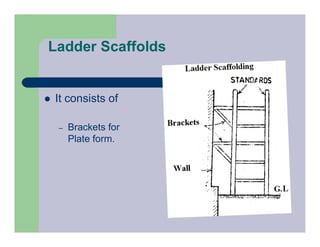

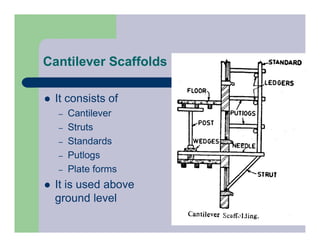

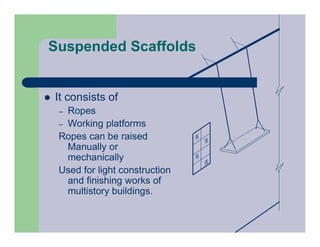

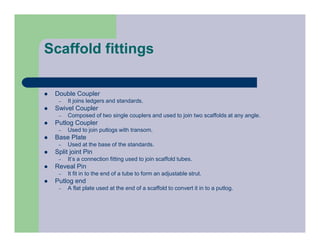

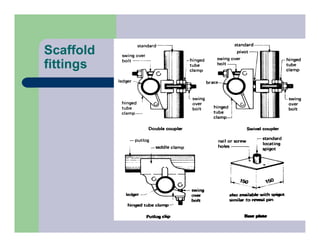

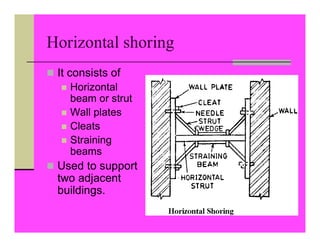

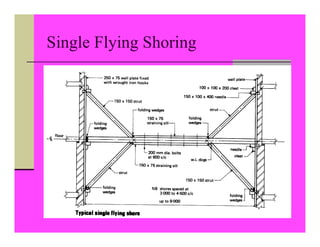

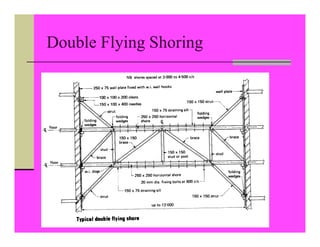

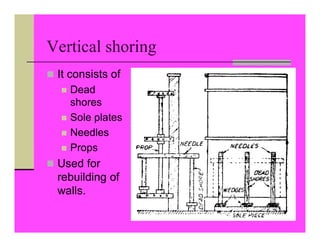

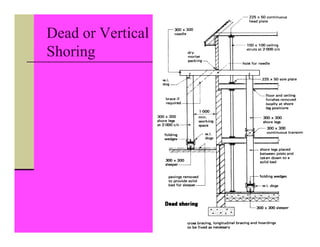

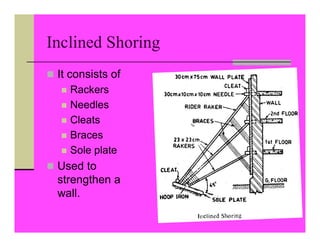

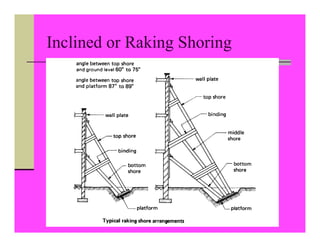

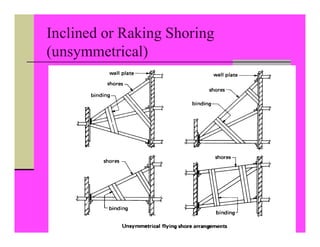

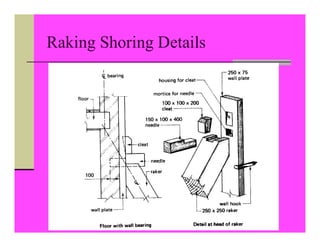

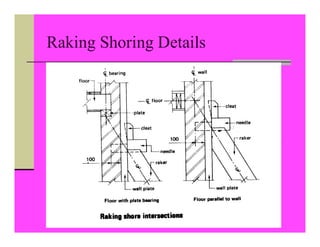

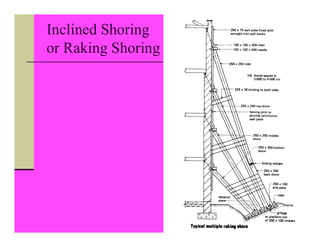

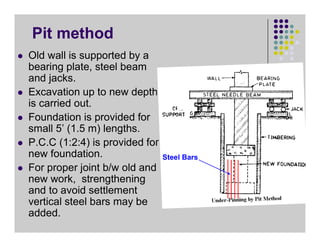

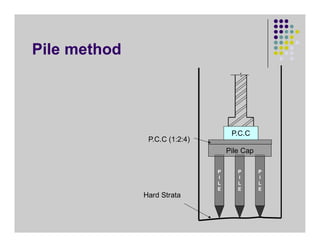

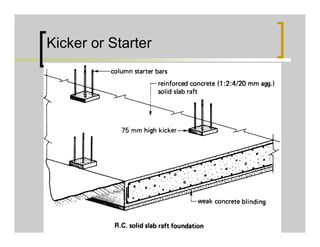

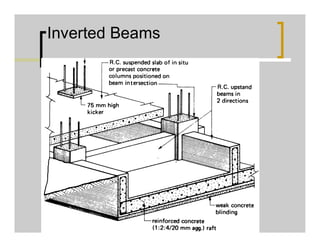

This document provides information on formwork, scaffolding, and shoring used for construction projects. It defines each term and discusses the types, materials, and uses. For formwork, it describes the qualities, types including steel and wood, and details for foundations, walls, columns, slabs, beams, and stairs. It also addresses removal times, maintenance, costs, and advantages of steel formwork. For scaffolding, it outlines types such as single, double, ladder, cantilever, suspended, and steel/tubular along with their components. Finally, it defines shoring and describes methods for horizontal, vertical, and inclined shoring as well as underpinning techniques.