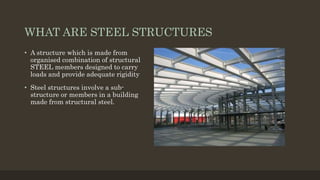

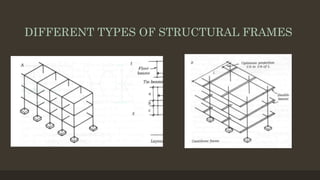

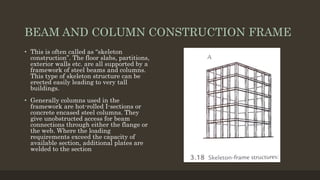

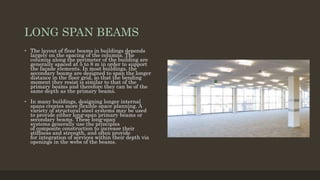

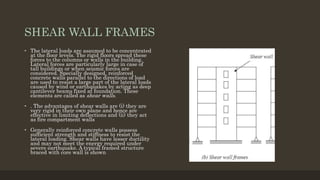

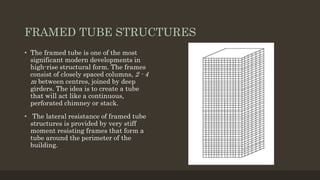

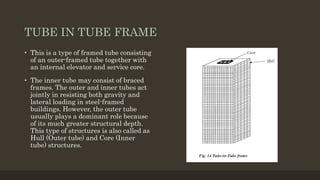

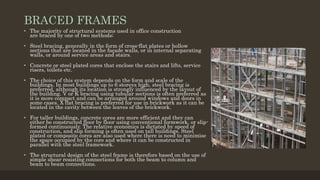

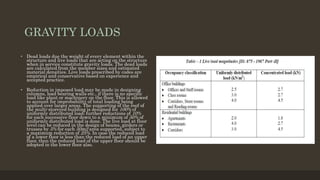

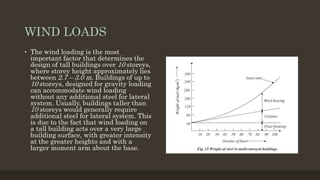

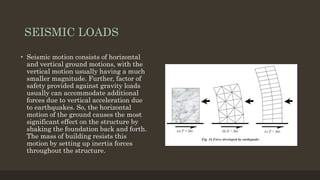

Steel structures involve structural steel members designed to carry loads and provide rigidity. They are commonly used in high-rise buildings, industrial buildings, warehouses, and temporary structures due to their strength, light weight, and speed of construction. Advantages include quick construction, flexibility, and ability to take various shapes. Disadvantages are reduced strength at high temperatures and susceptibility to corrosion. Common structural steel frames include beam and column construction, trusses, space frames, shear wall frames, framed tube structures, and braced frames. Design must consider both gravity loads like dead and live loads, as well as lateral loads from wind and earthquakes.