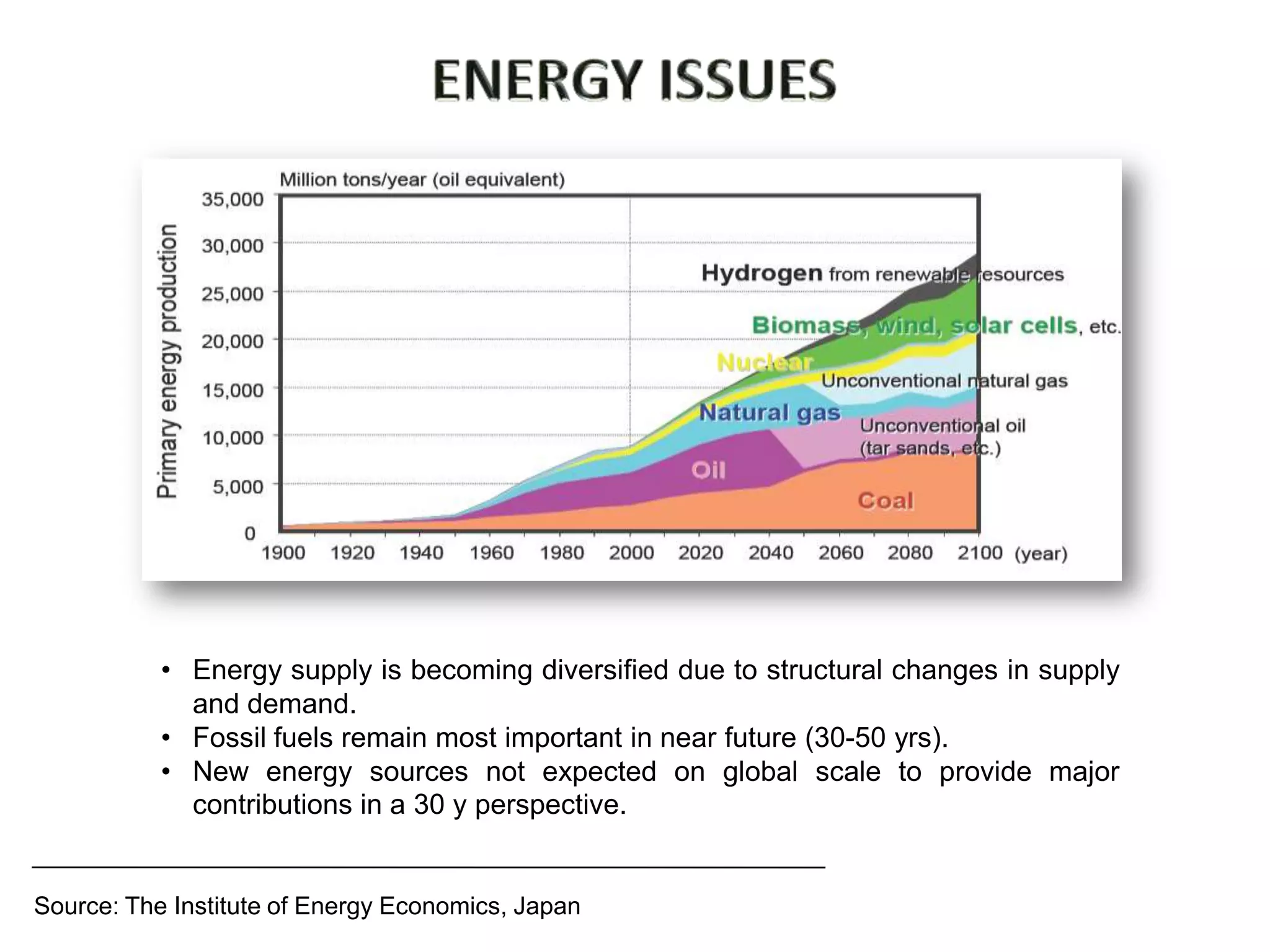

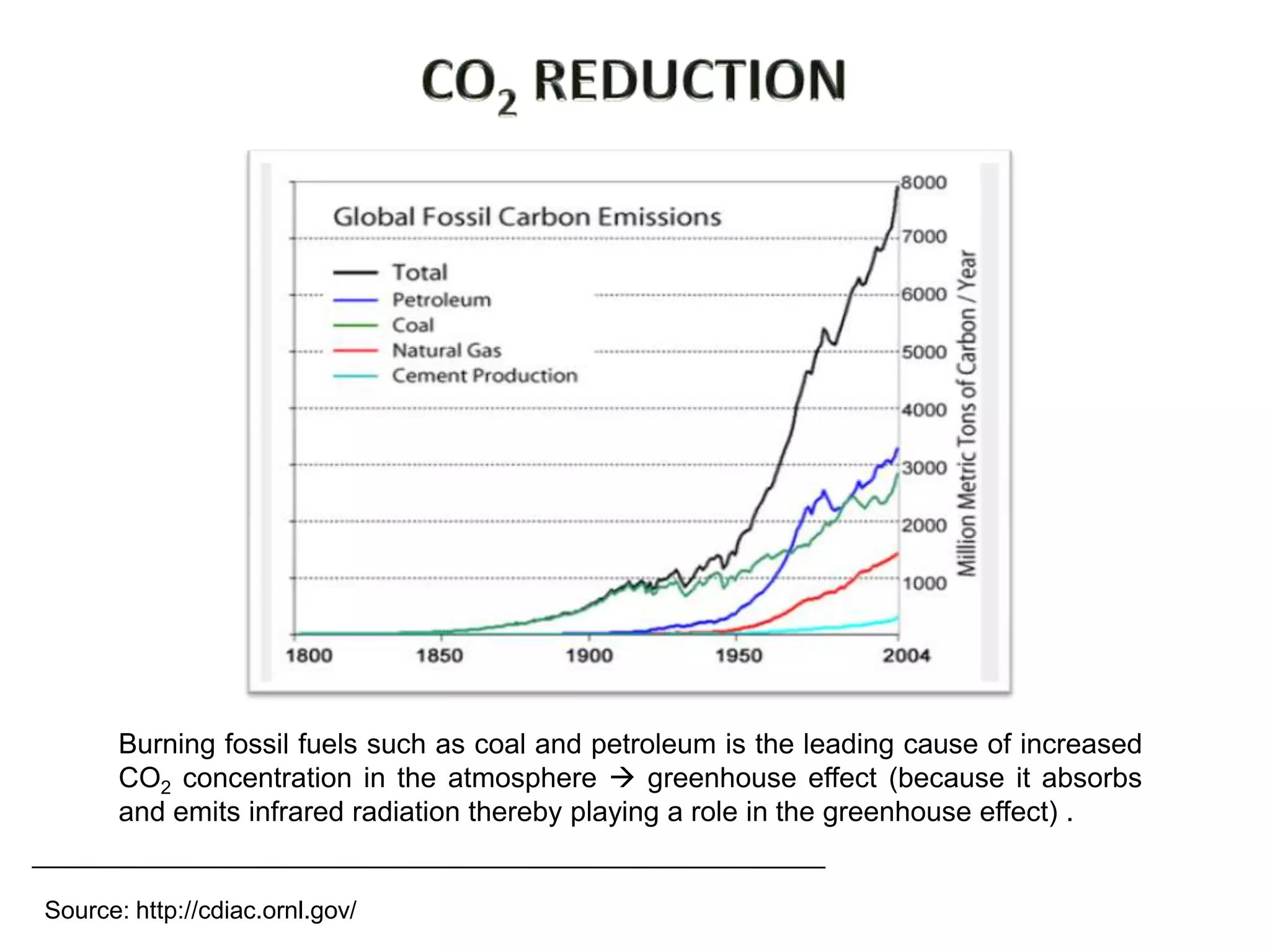

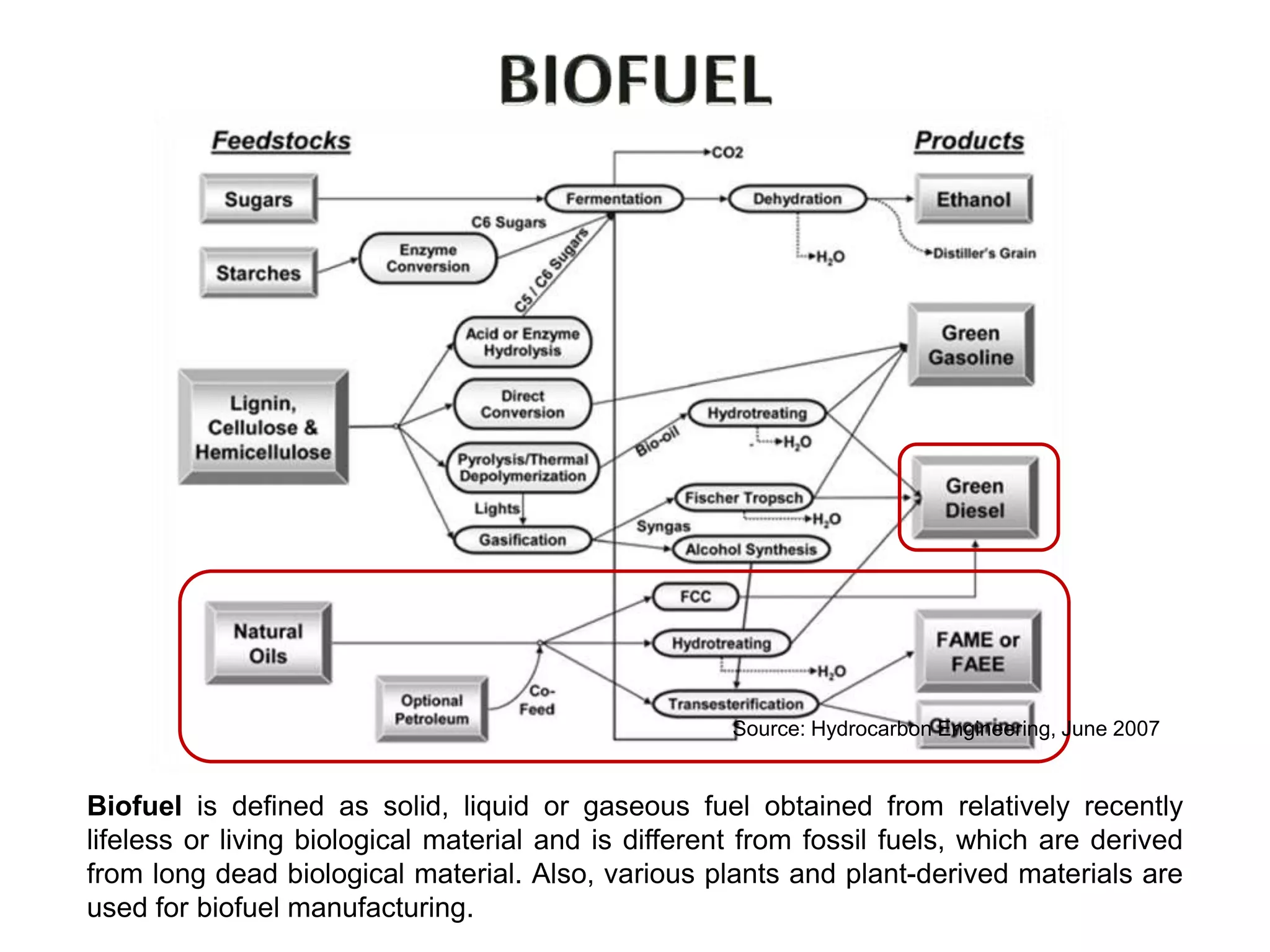

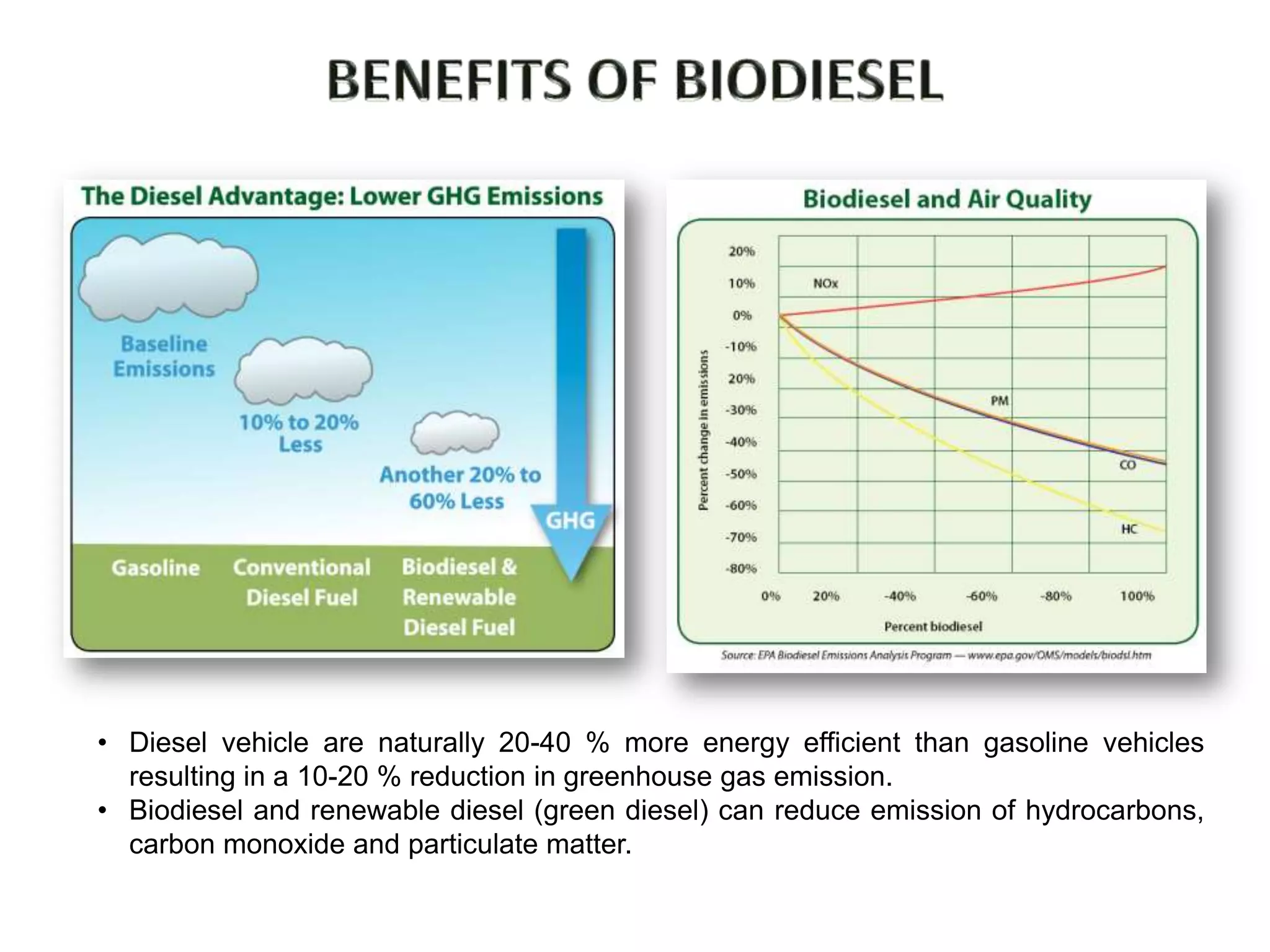

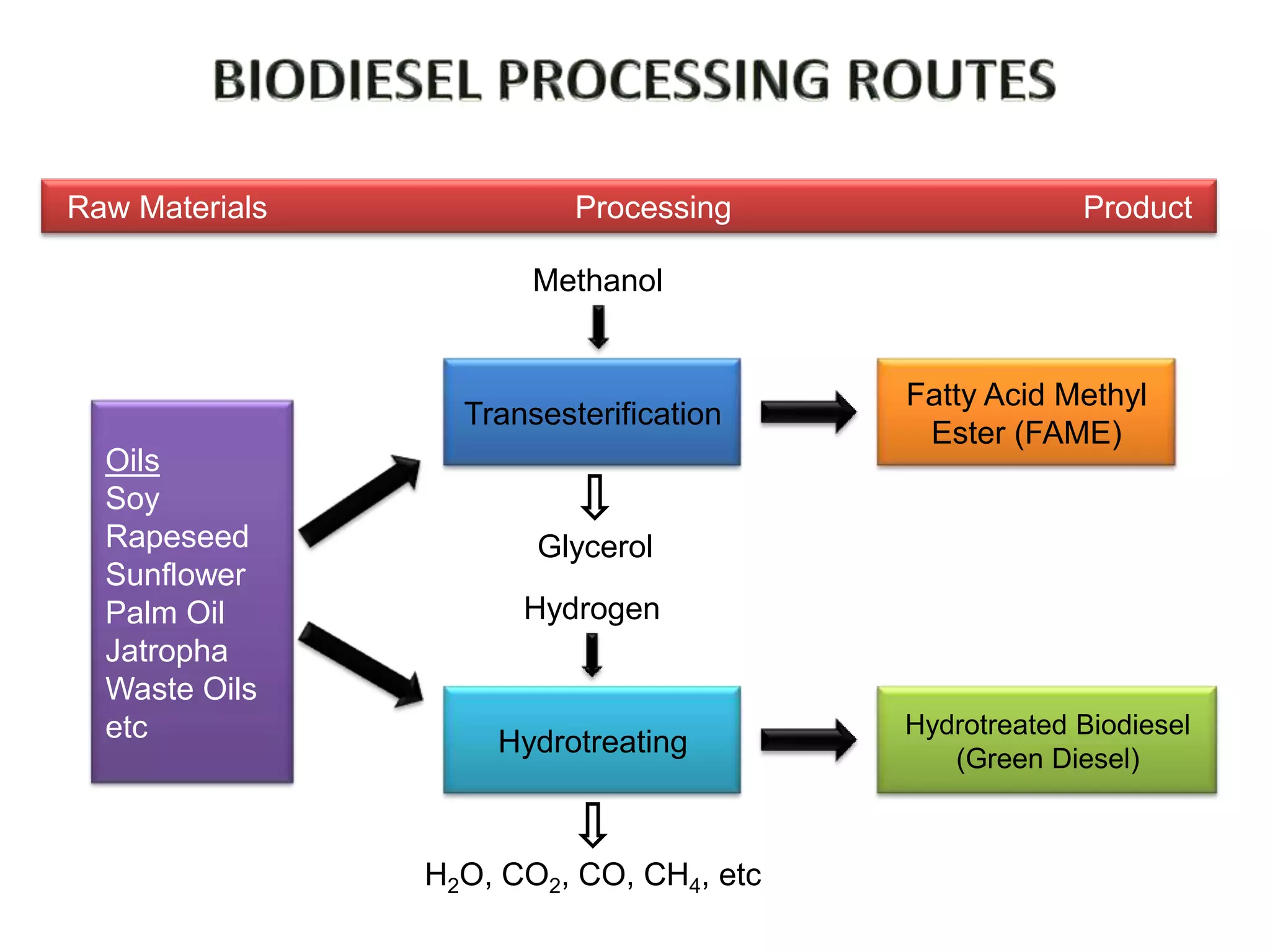

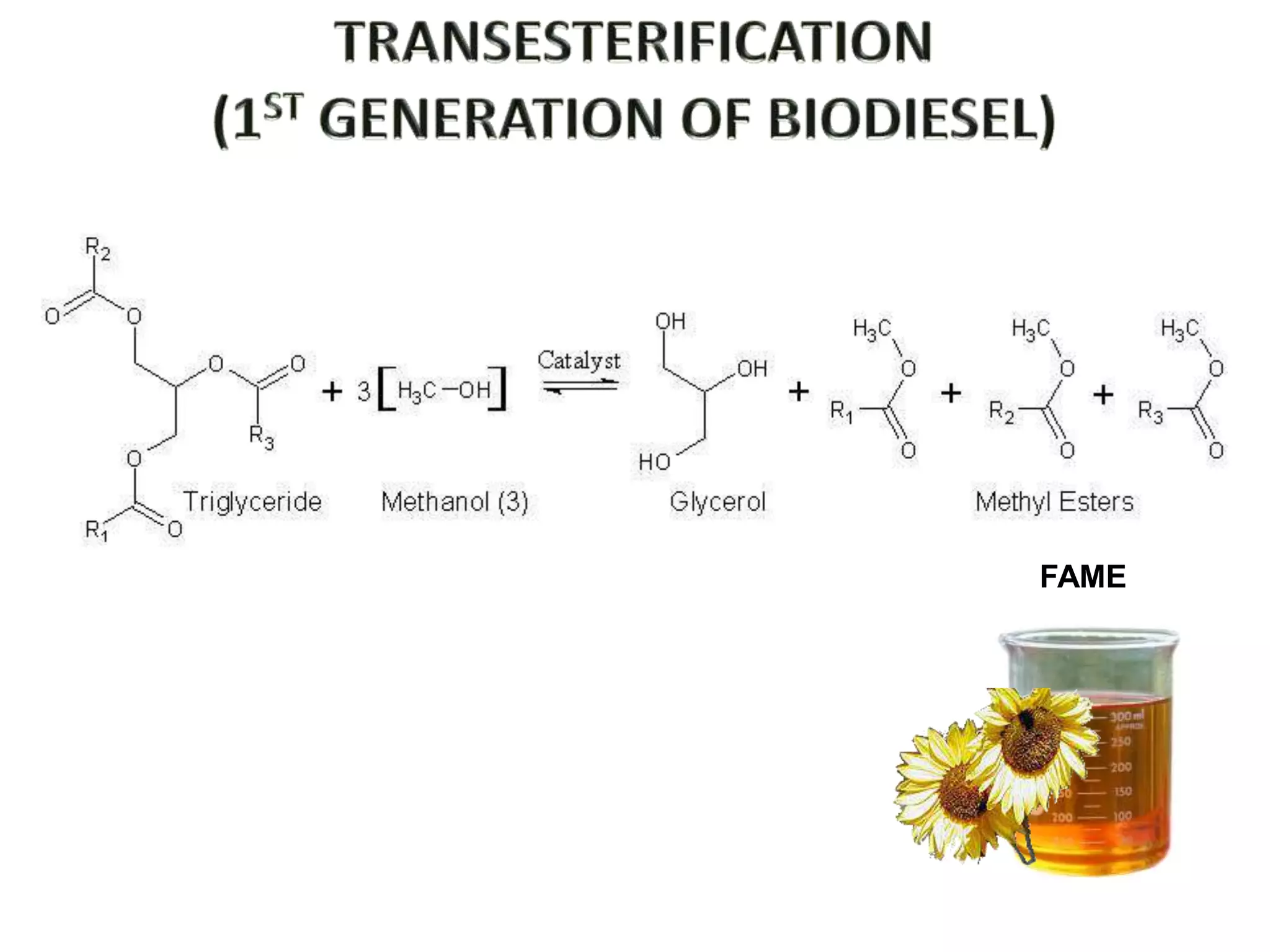

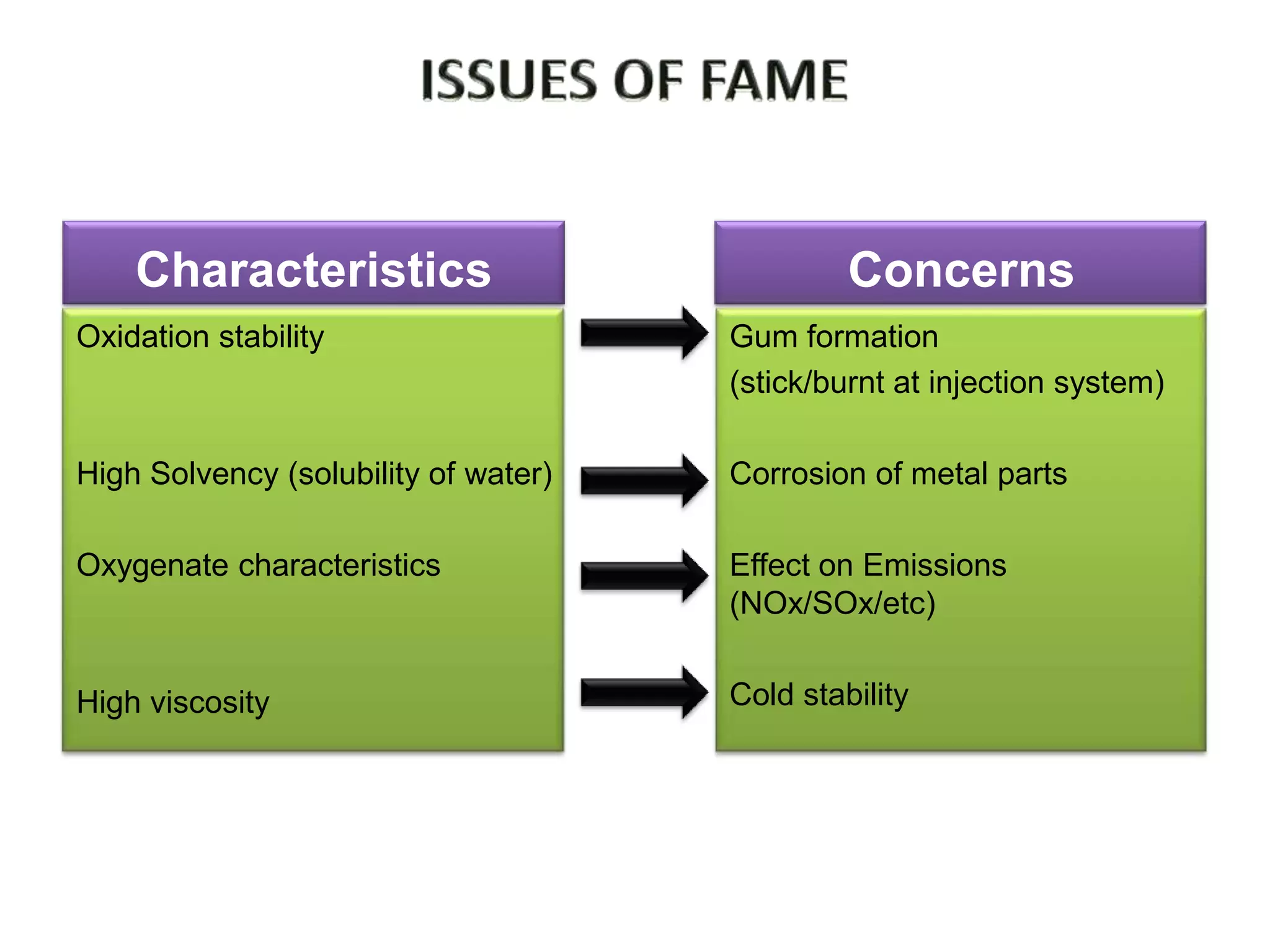

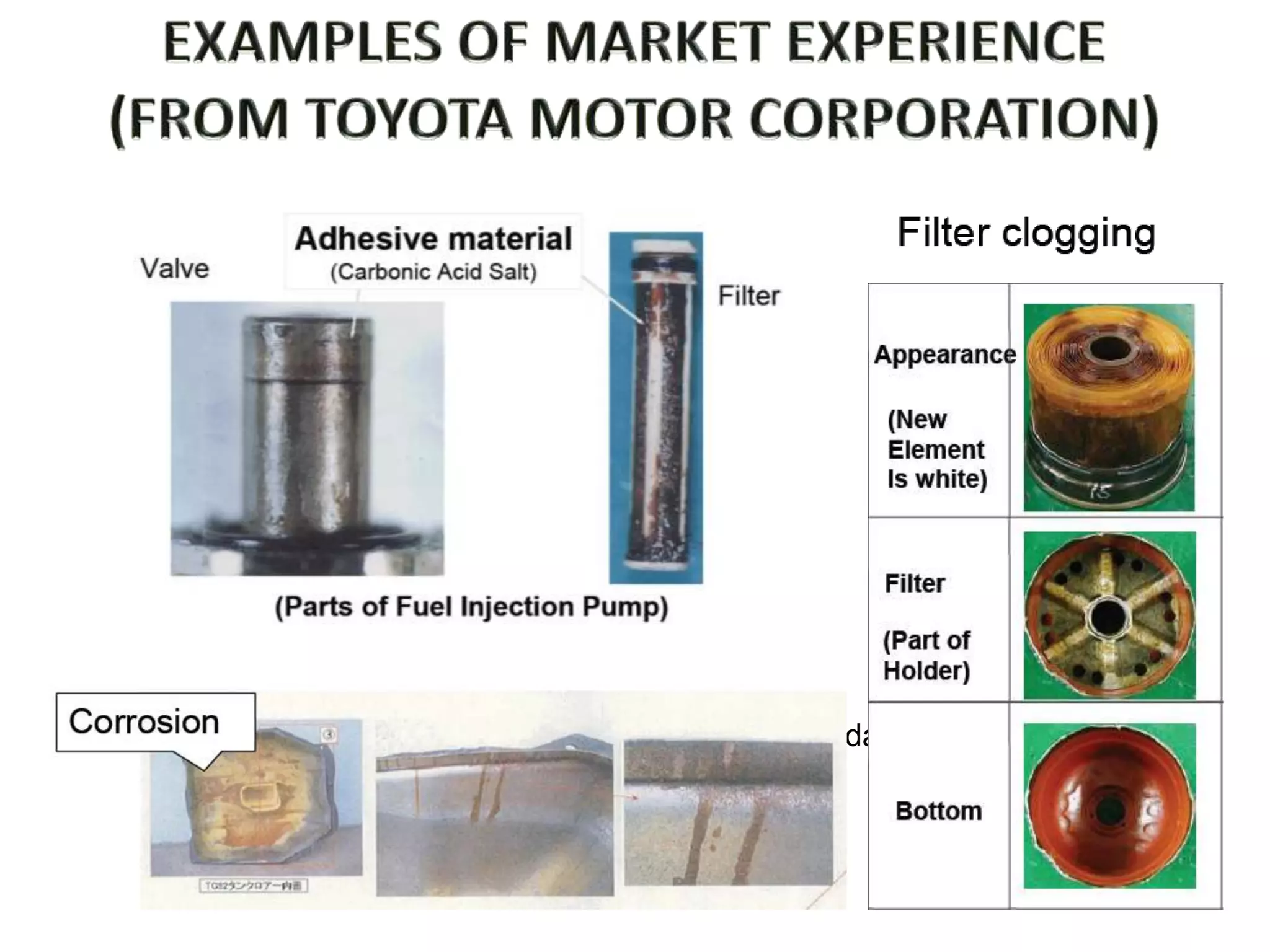

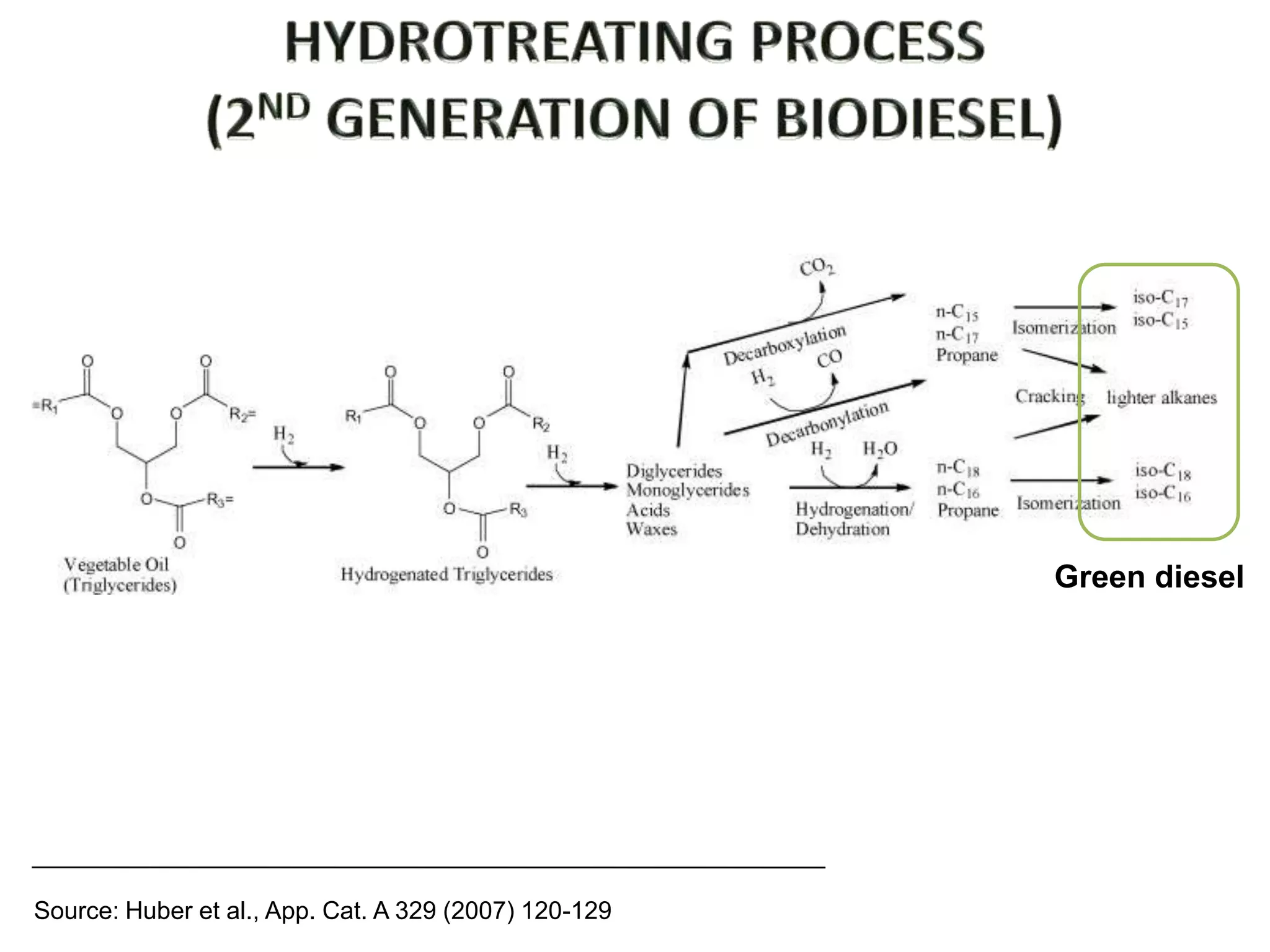

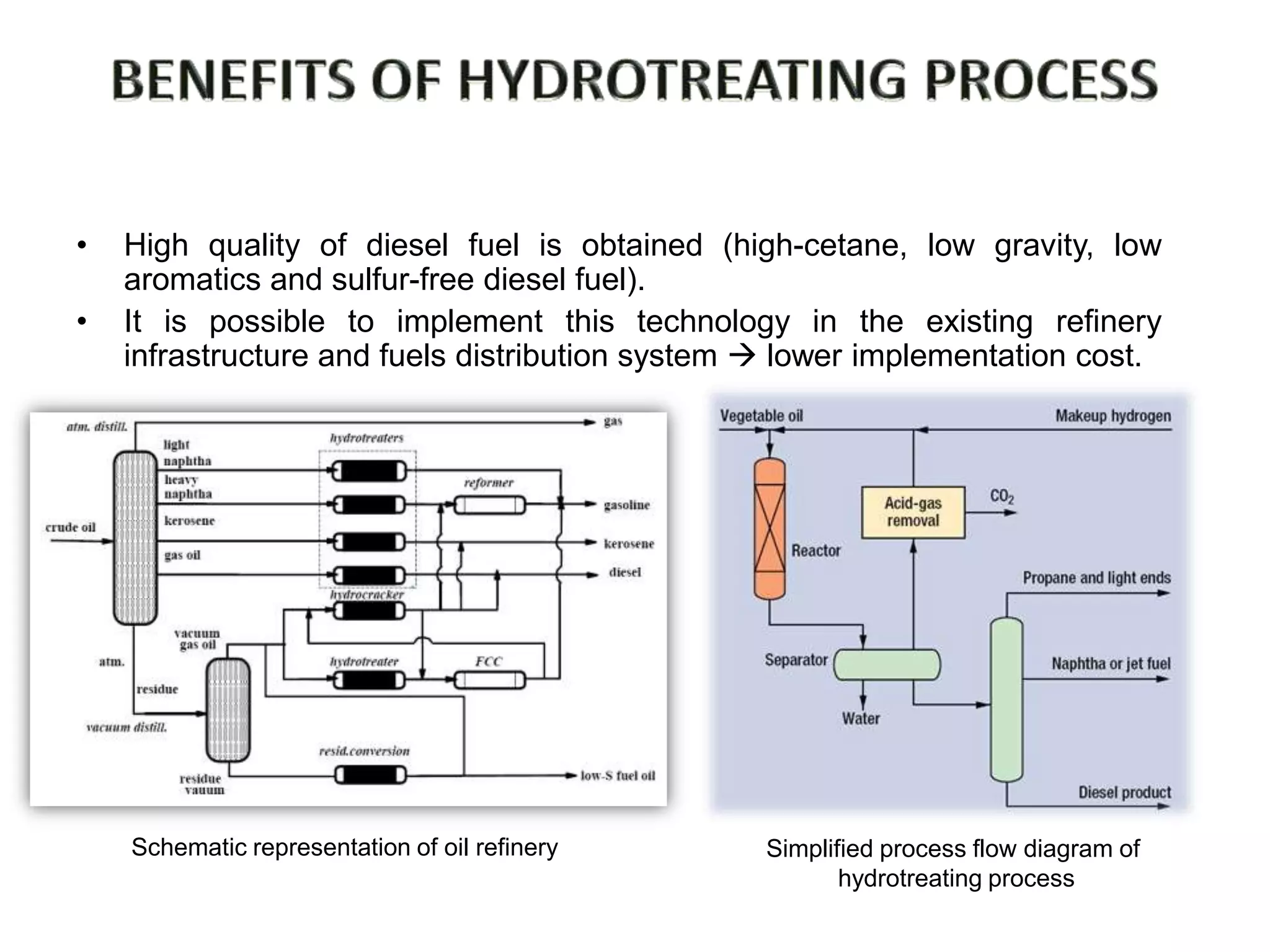

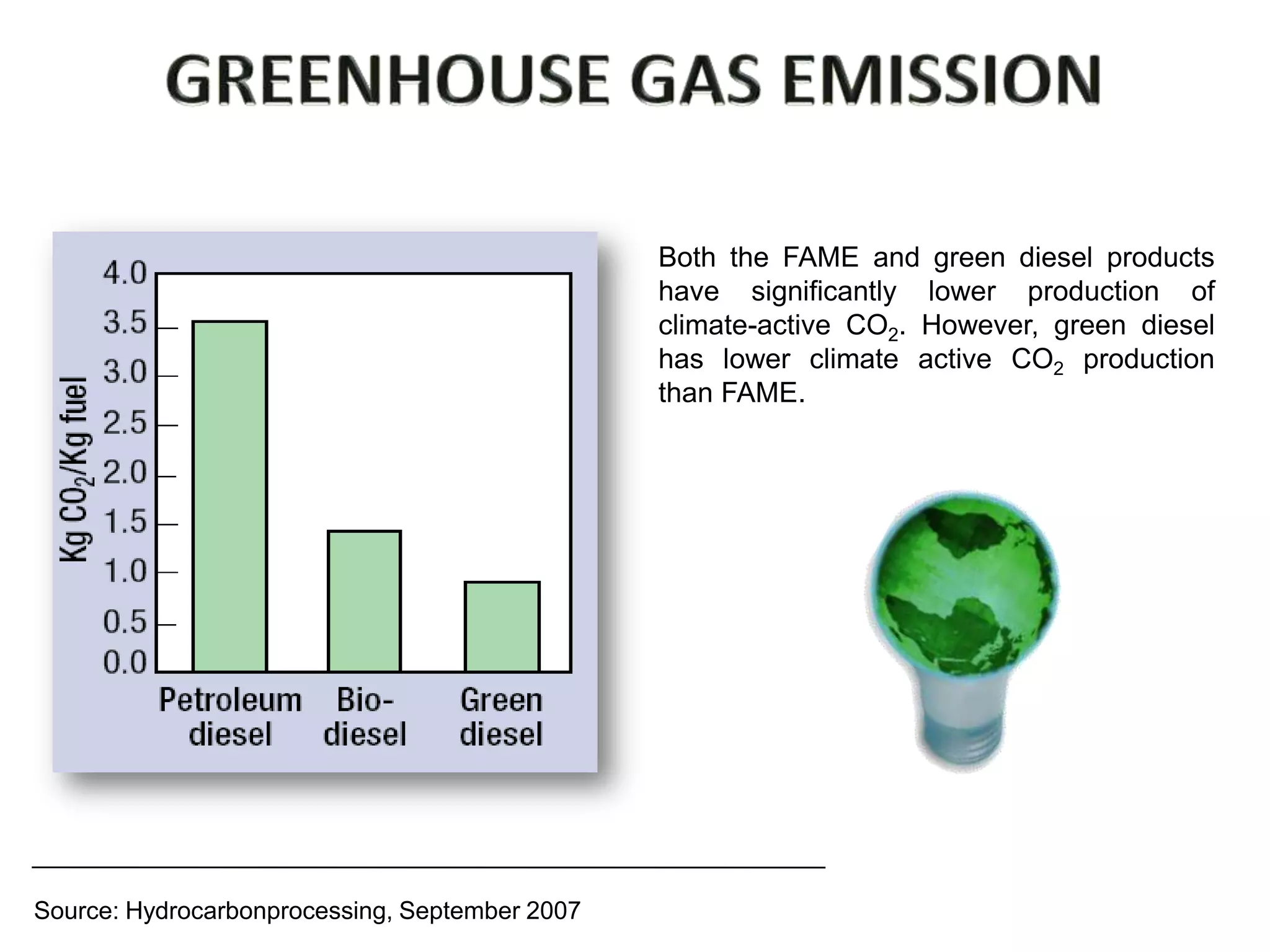

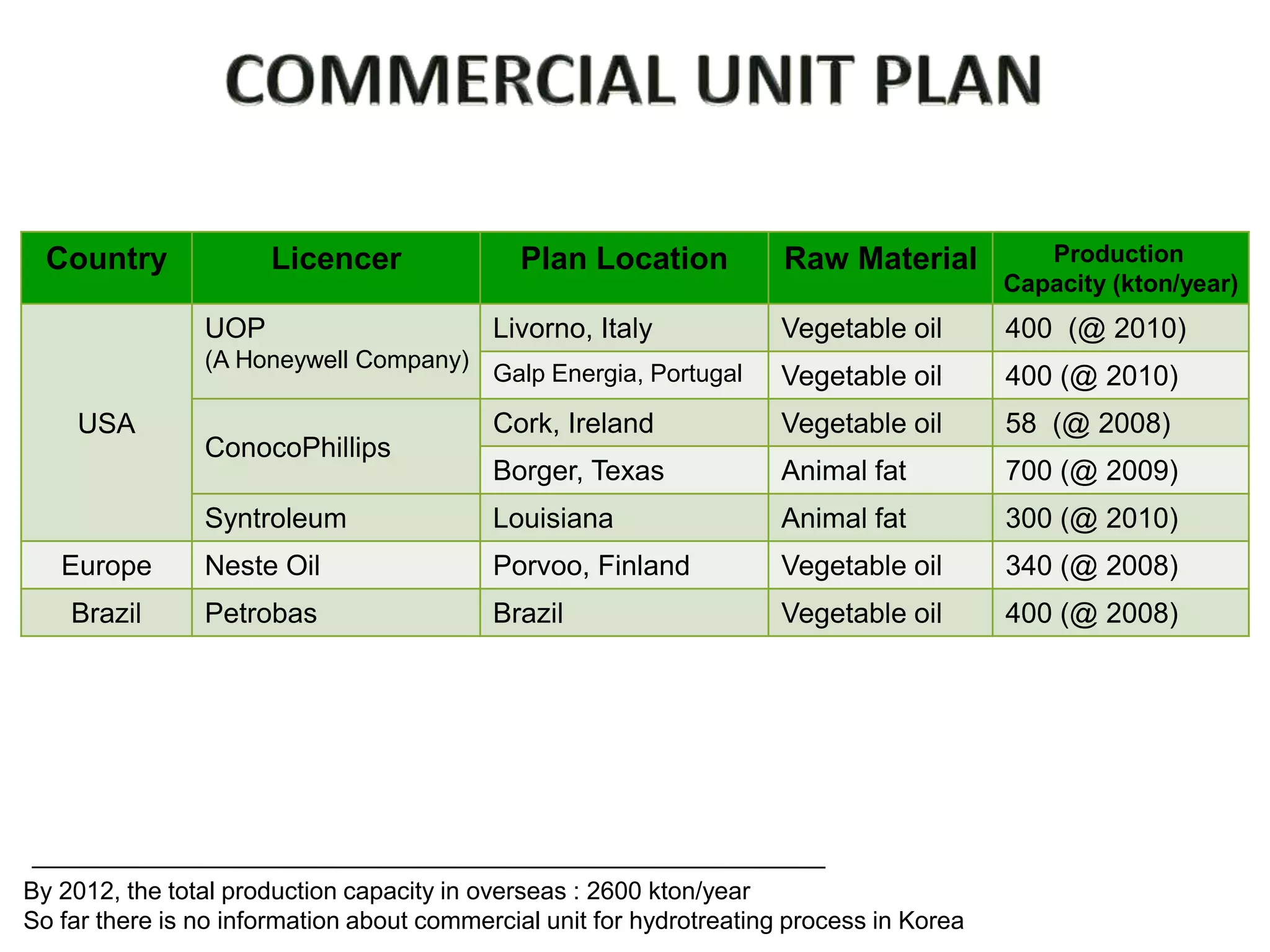

This document discusses renewable energy sources and green diesel production. It provides information on various feedstocks used to produce biofuels like biodiesel and green diesel. Green diesel produced through hydrotreating has similar properties to petroleum-based diesel but with benefits like lower emissions. Several companies have built or plan to build commercial facilities overseas to produce green diesel at large scale using various fats and oils. However, no commercial hydrotreating units currently exist in Korea.