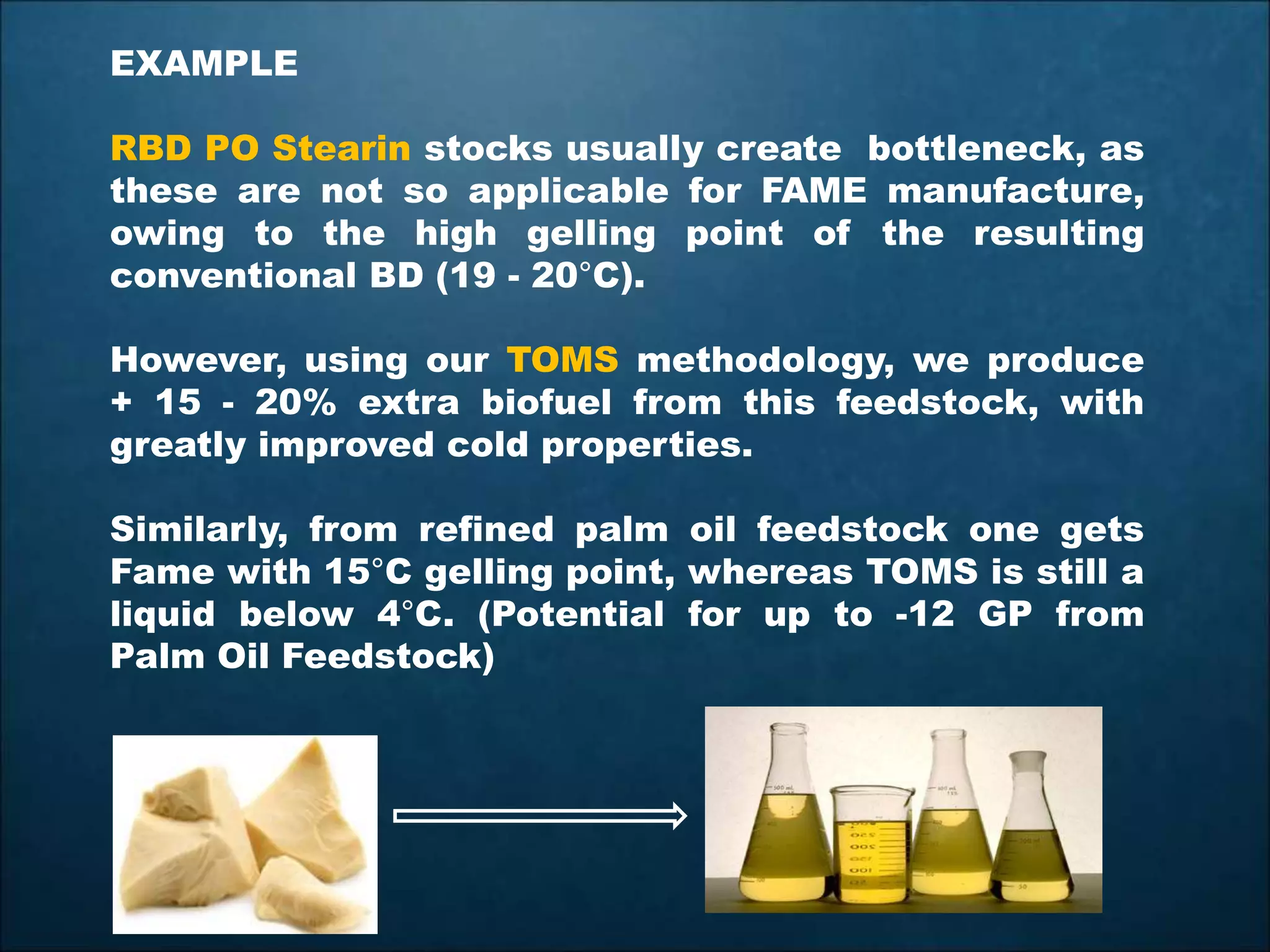

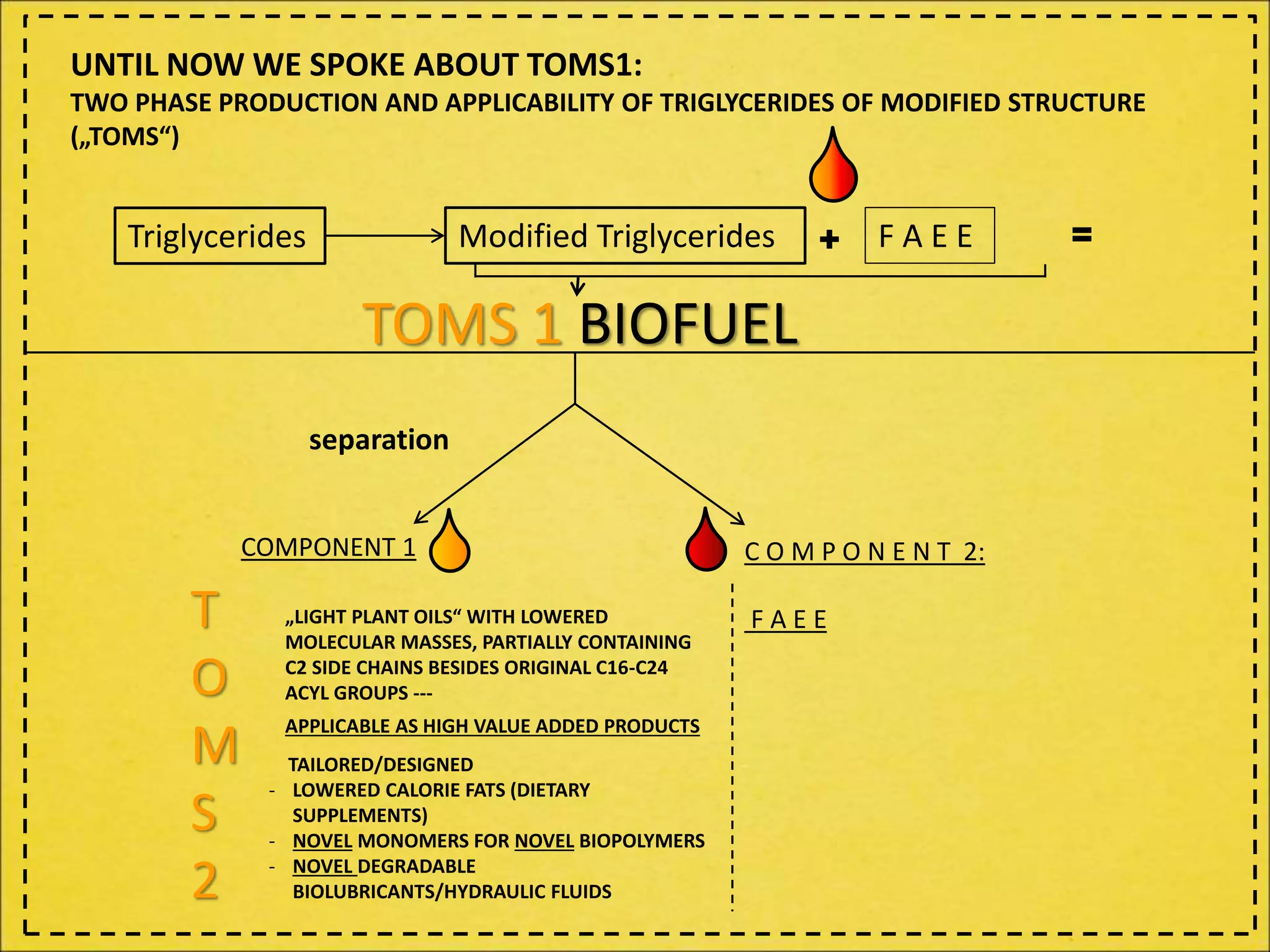

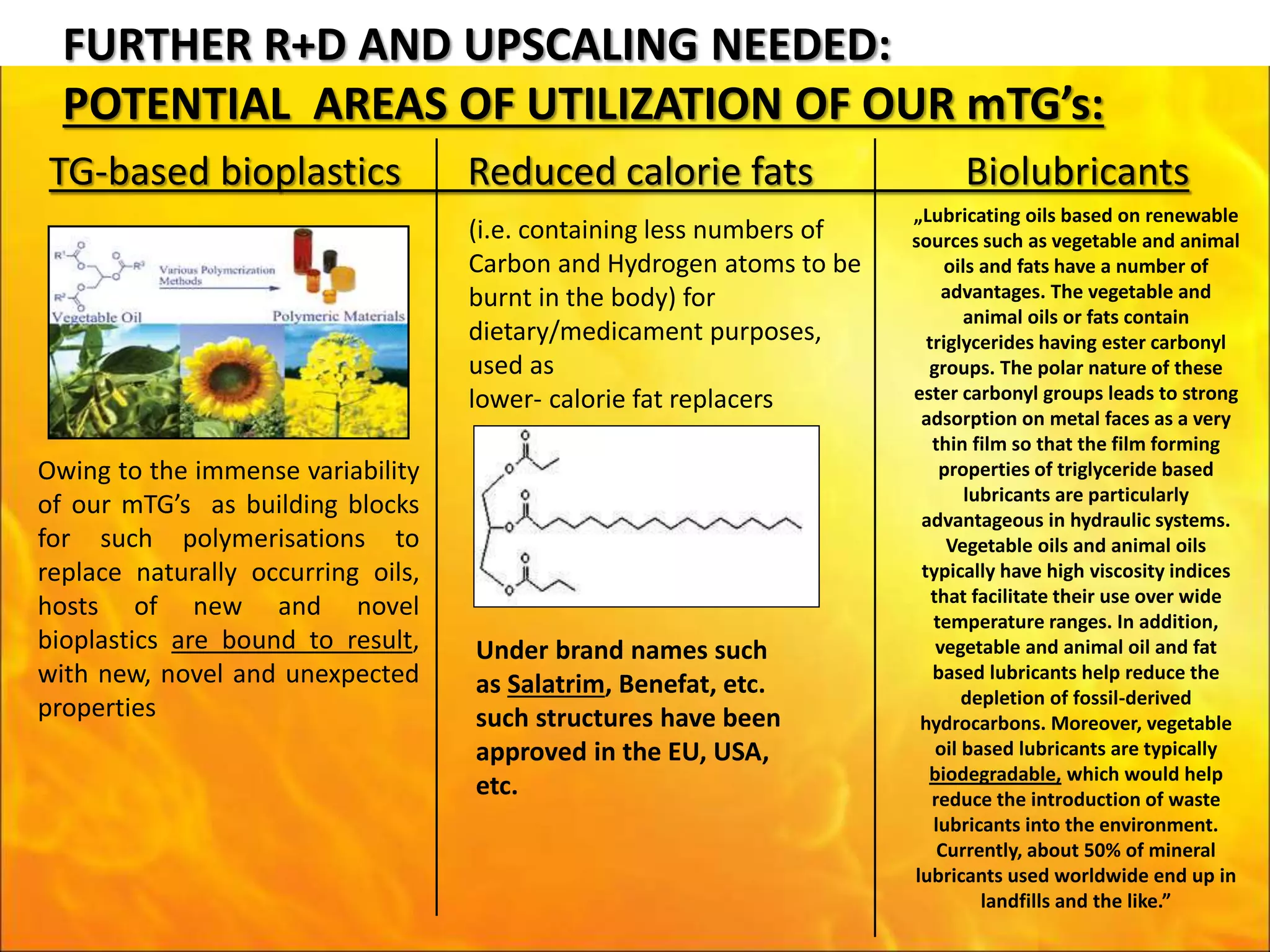

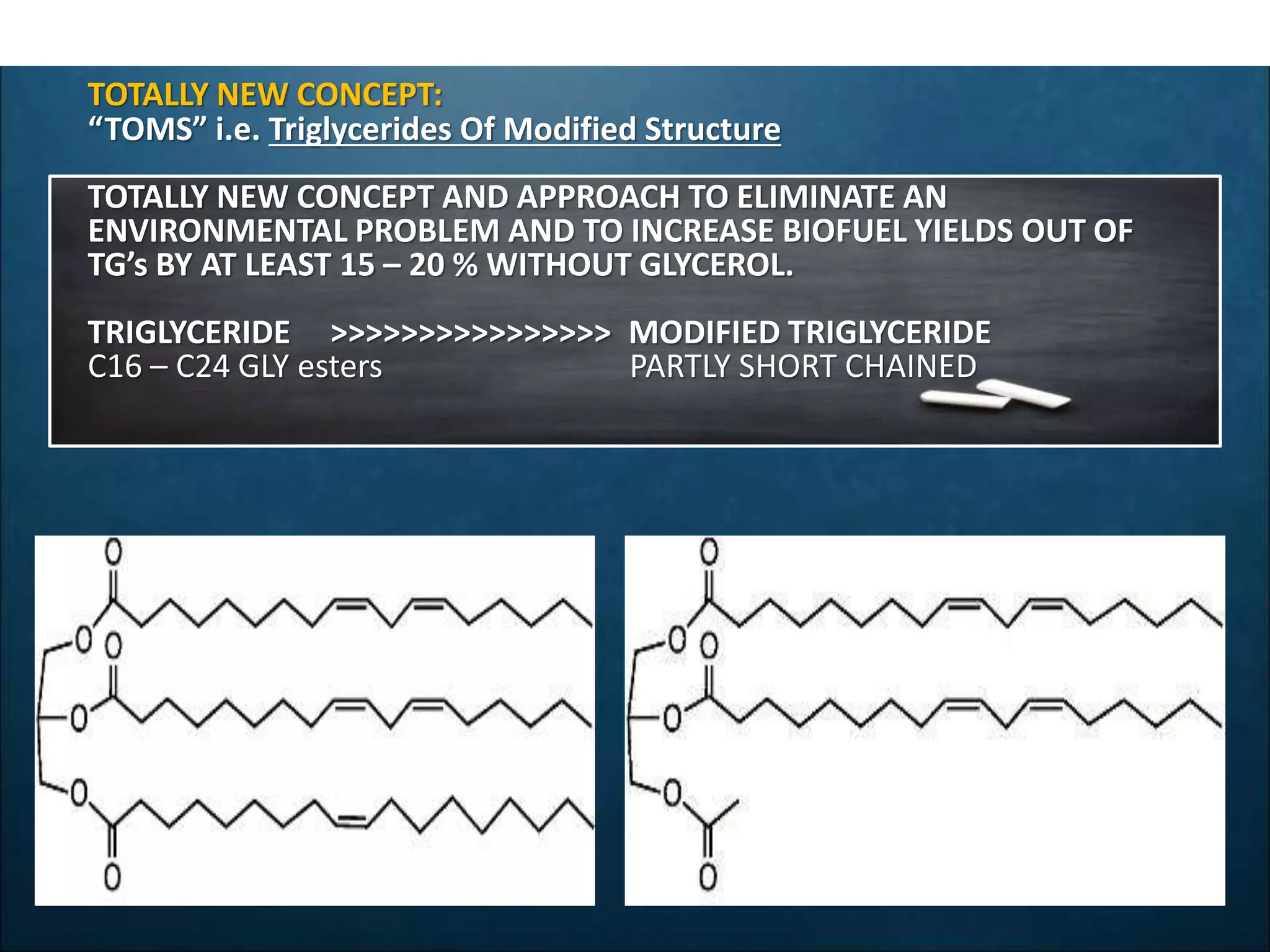

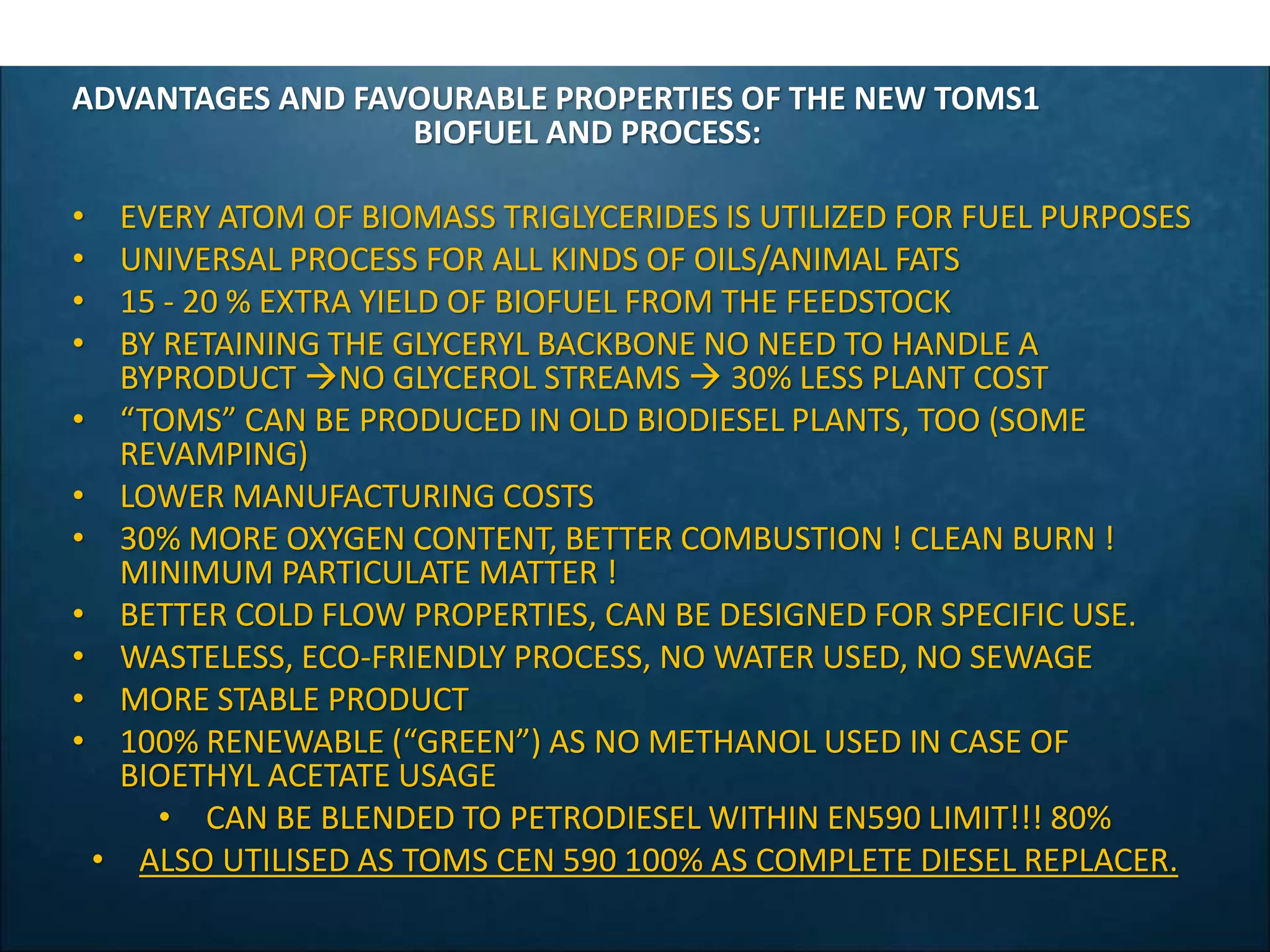

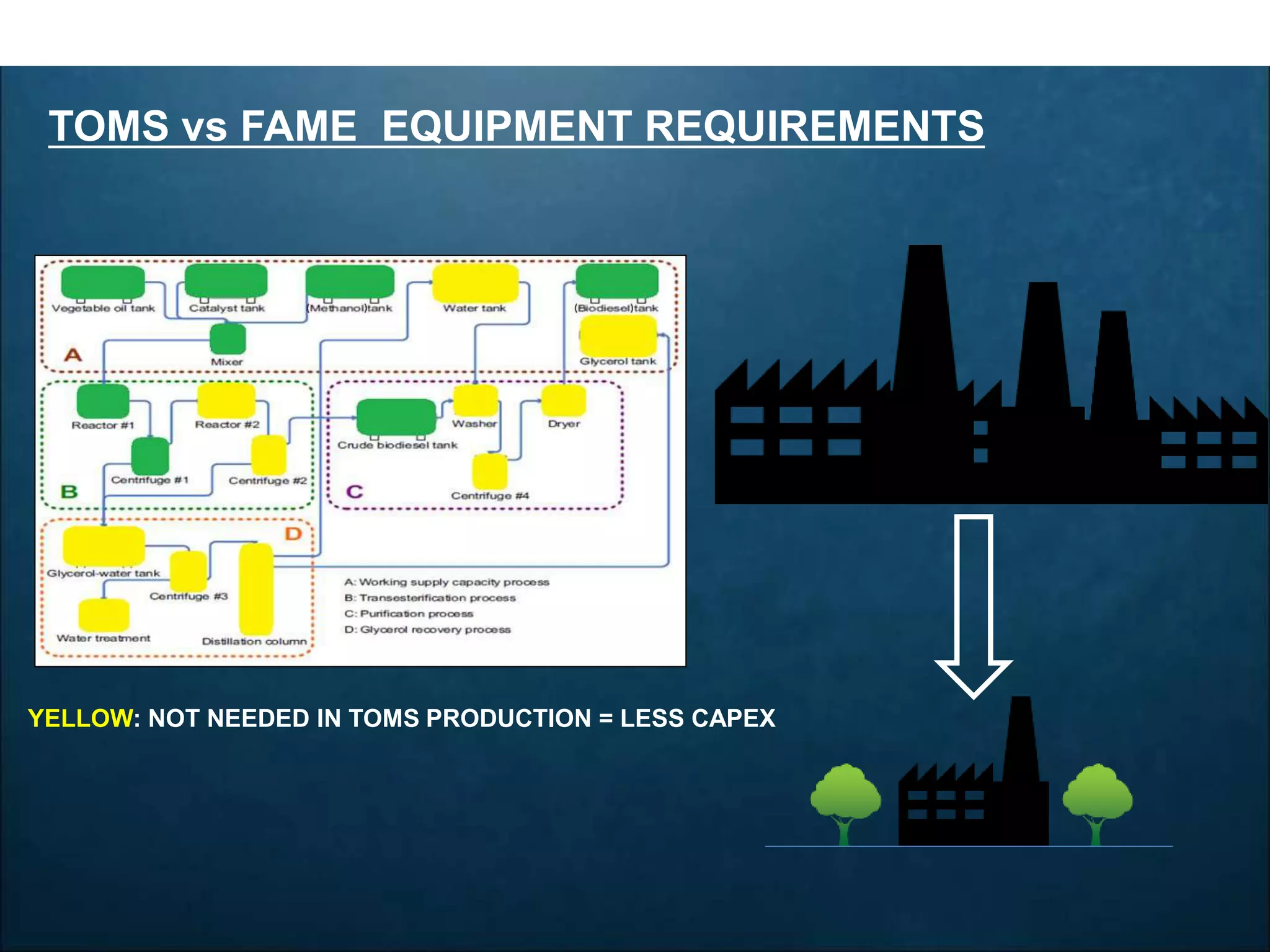

Triglycerides of Modified Structure (TOMS) is a novel biofuel and chemical feedstock produced from natural oils and fats. TOMS provides 15-20% higher biofuel yields compared to conventional biodiesel without producing glycerol as a byproduct. TOMS can also be used to produce a limitless number of tailored molecules for oleochemical industries. The process for producing TOMS is universal for all types of oils and fats, utilizes every atom of biomass, has lower production costs than biodiesel, and produces a more stable and cleaner-burning fuel. In addition to its use as a biofuel, TOMS can be modified to produce novel bioplastics, lubricants, and

![Visual Difference:

FAME + Glycerol vs. TOMS from the same

volume of feedstock oil

a. FAME

b. Glycerol

c. TOMS, no glycerol, but + 15 - 20 % extra

fuel mass

7.01 7.00 6.70 6.45 6.23 5.98 5.56

7.12

6.42 6.75

6.18

5.51

4.98

5.61

0.00

2.00

4.00

6.00

8.00

992.2 1196.4 1292.9 1392.5 1593.8 1789.7 1894.7

SpecificNOxemission

[g/kWh]

Engine speed [1/min]

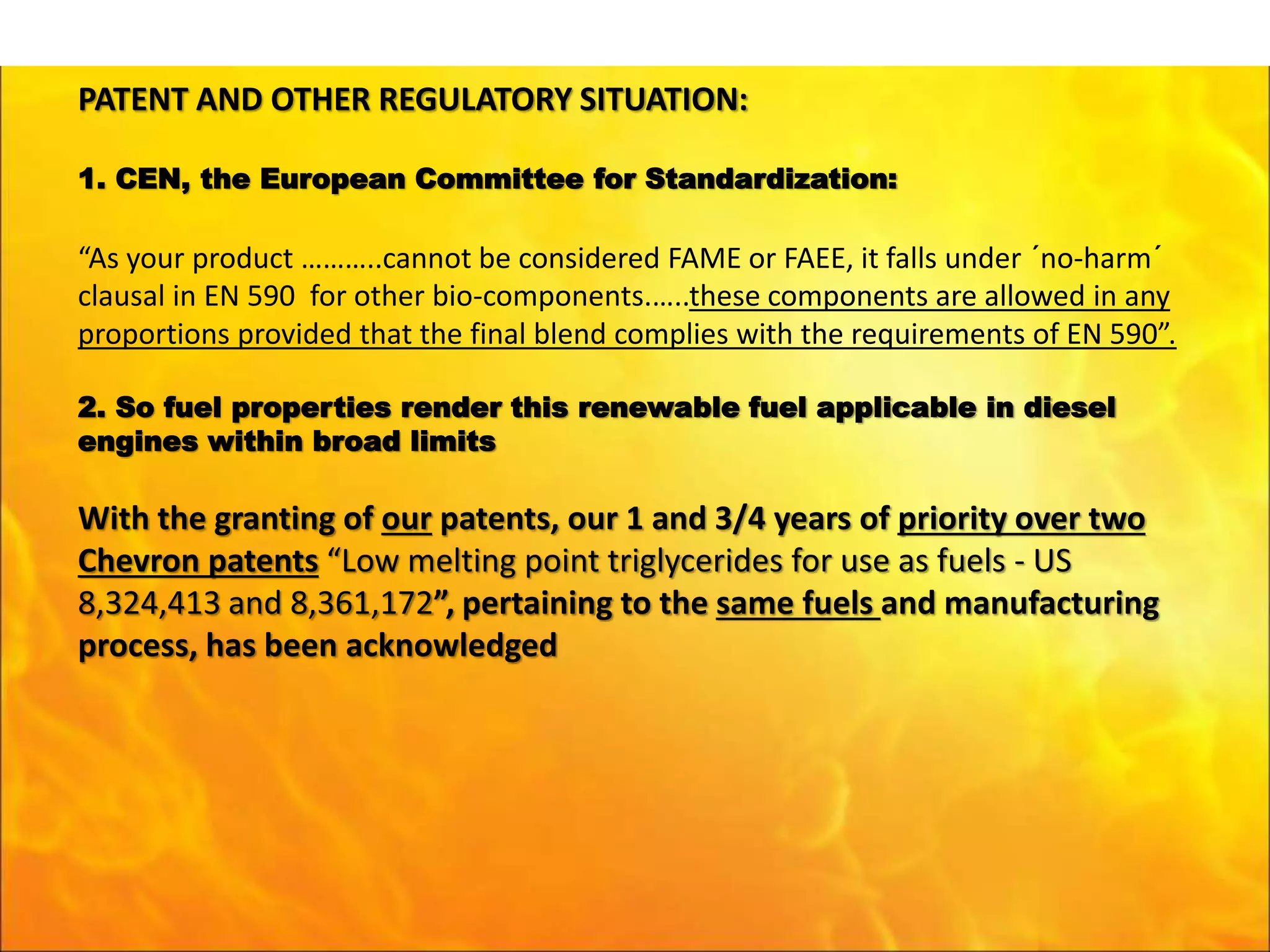

Comparison of the specific NOx emissions while engine full load

Specific

NOx

emission -

Diesel fuel

Specific

NOx

emission -

TBK

Biodiesel

0.680

0.380

0.230

0.190

0.118

0.078 0.106

0.110

0.085 0.070

0.042 0.027 0.015 0.0150.000

0.200

0.400

0.600

0.800

992.2 1196.4 1292.9 1392.5 1593.8 1789.7 1894.7

Smoke[1/m]

Engine speed [1/min]

Comparison of the smoke values while engine full load

Smoke

values -

Diesel fuel

0.502 0.523

0.501

0.468

0.513

0.488 0.480 0.459 0.442

0.485

0.090 0.092 0.086 0.097 0.099 0.093 0.089 0.091 0.085 0.088

0

0.1

0.2

0.3

0.4

0.5

0.6

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

Smoke[1/m]

Measure ordinal number

Comparison of the free peak smoke values

Free peak

smoke - Diesel

fuel

Free peak

smoke - TBK

Biodiesel

Better Emission Values than Petrodiesel

c

a

b](https://image.slidesharecdn.com/f56636c6-856f-4acc-b209-db1825ae8423-150524000552-lva1-app6892/75/TOMS-short-presentation-3-Autosaved-6-2048.jpg)