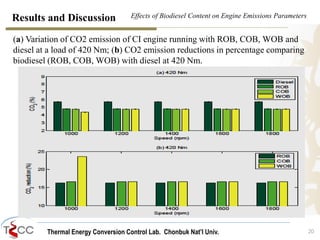

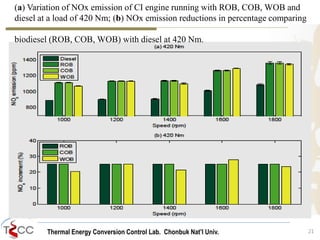

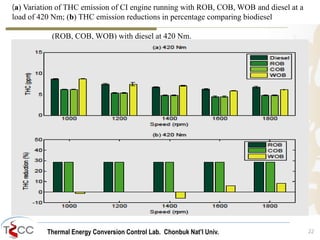

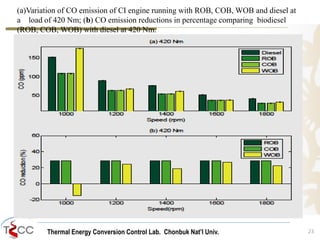

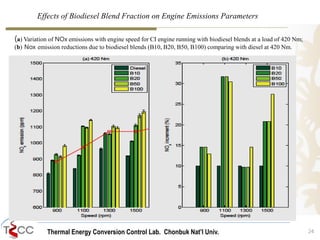

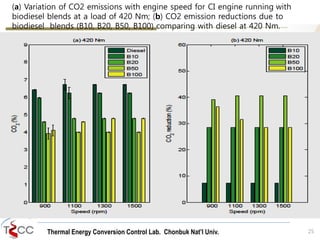

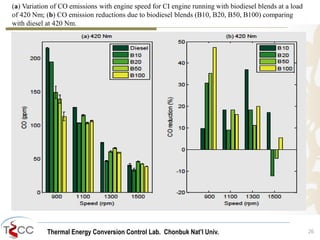

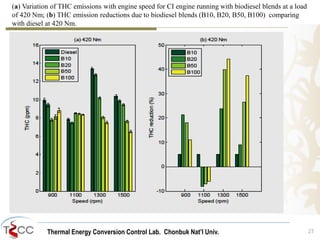

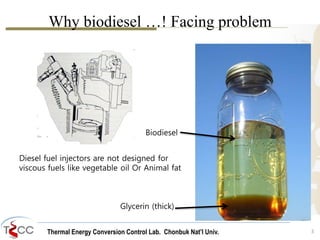

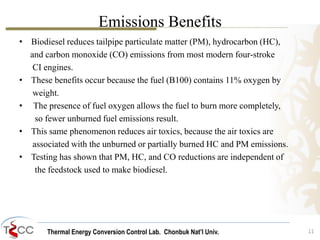

The document discusses a study that investigated the effects of different biodiesel types and biodiesel fractions on emission characteristics of a compression ignition engine. The study found that biodiesel from different feedstocks did not significantly affect emissions as long as fuel properties remained the same. Emissions of CO2, CO and THC decreased with increasing biodiesel content, while NOx emissions increased. The conclusions were that biodiesel reduces emissions except for NOx, and the feedstock source does not significantly impact emissions.

![Thermal Energy Conversion Control Lab. Chonbuk Nat’I Univ.

Table 1. Estimated share of literature (in % number of publications)on effect

of pure biodiesel on engine performance and emission in comparison with

diesel [12,13].](https://image.slidesharecdn.com/june201411-140610223711-phpapp01/85/June-2014-11-12-320.jpg)

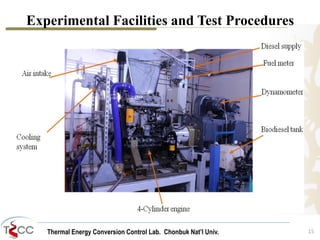

![Thermal Energy Conversion Control Lab. Chonbuk Nat’I Univ. 16

Figure 2. Engine test facilities layout [37].](https://image.slidesharecdn.com/june201411-140610223711-phpapp01/85/June-2014-11-16-320.jpg)