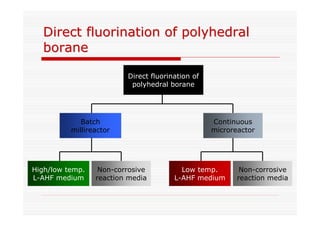

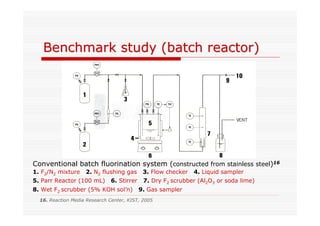

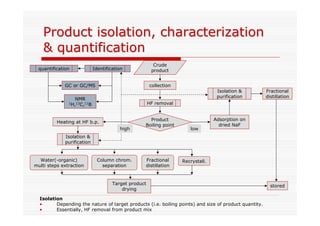

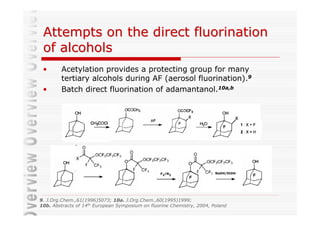

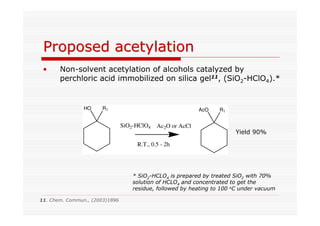

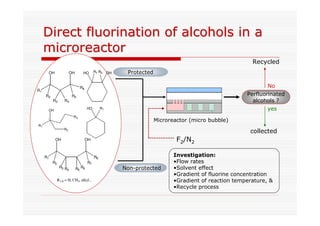

The document discusses direct fluorination reactions in microreactors. It proposes acetylating alcohols prior to fluorination to protect the alcohol group. The fluorination would take place in a microreactor using a gas-liquid system with elemental fluorine and nitrogen. Previous attempts at direct fluorination of alcohols and polyhedral boranes in batch reactors are described. The document outlines characterization techniques that could be used to analyze products from the proposed microreactor fluorination experiments.

![Synthesis of

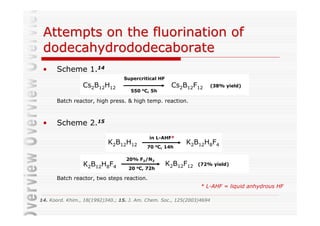

dodecahydrododecaborate

Scheme 1.12

• Na[B3H8] in diglyme, reflux under nitrogen until colorless, then

diglyme

NaBH4 + I2 Na[B3H8] + NaI + H2

Reflux 100 oC

under N2

Scheme 2.13

• Na[B3H8] treated with concentrated (CH3)3NHCl in water and

cooled to R.T. The solid is separated, dried, and recrystallized

from water-ethyl alcohol to give (Me3NH)2B12H12.

diglyme

NaB3H8 + [HNMe3]Cl [HNMe3]2B12H12 + NaCl

100 oC, under N2

12. Yingyong Huaxue, Chem. Abstr., 15(1998)111.; 13. J. Am. Chem. Soc., 85(1963)3885](https://image.slidesharecdn.com/microreactor-fluorination-freiburg-111009231609-phpapp01/85/Microreactor-fluorination-freiburg-8-320.jpg)