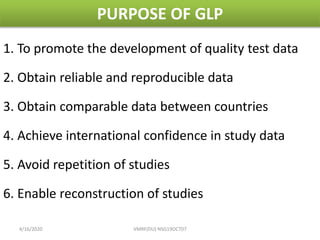

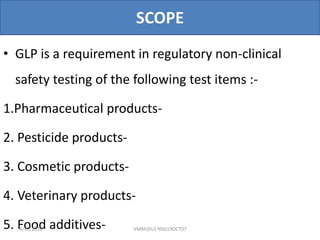

The document discusses Good Laboratory Practice (GLP) guidelines. It provides an introduction to GLP, including that GLP deals with how laboratory studies are planned, performed, monitored and reported to ensure quality and validity of test data. The history and purpose of GLP are then outlined, noting it was established to prevent fraud and promote standardized, high-quality non-clinical safety testing. Ten GLP principles are also summarized, covering topics like facilities, equipment and management responsibilities. Finally, the scope and current status of GLP in India are briefly addressed.