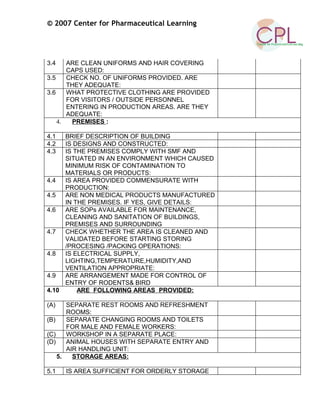

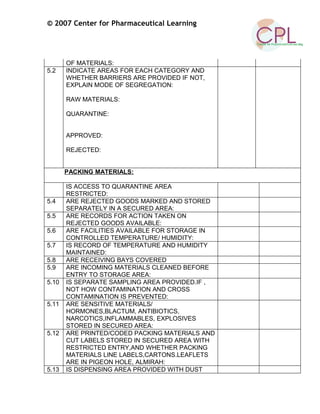

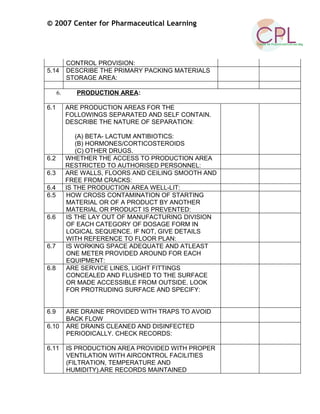

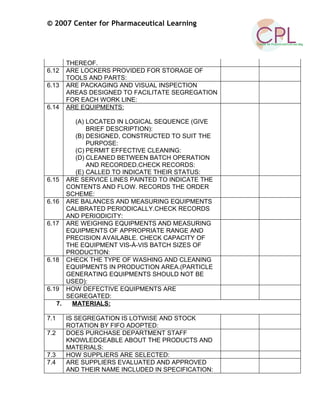

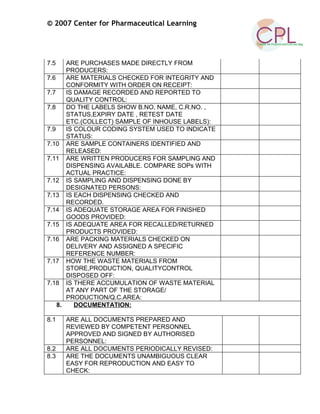

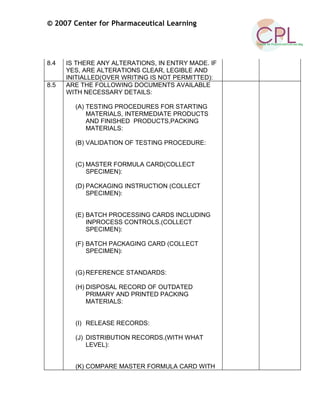

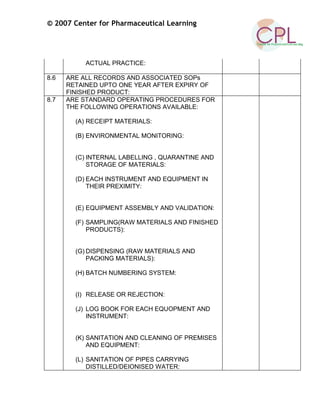

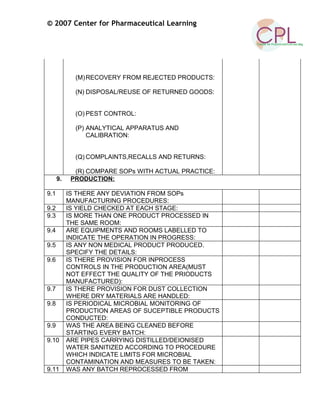

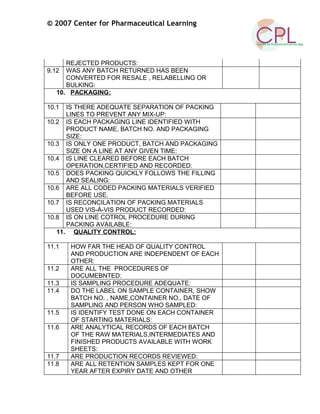

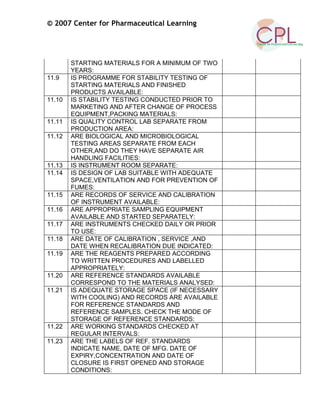

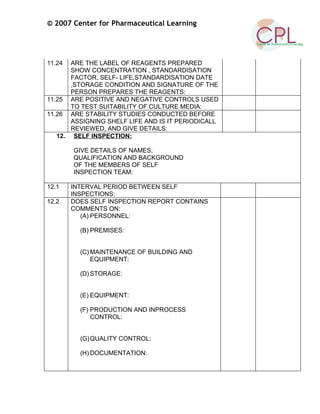

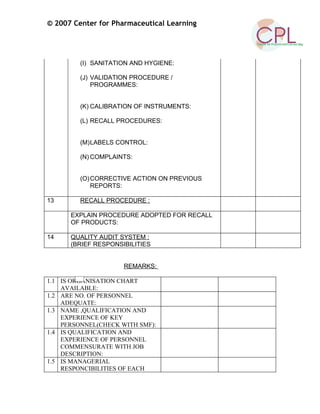

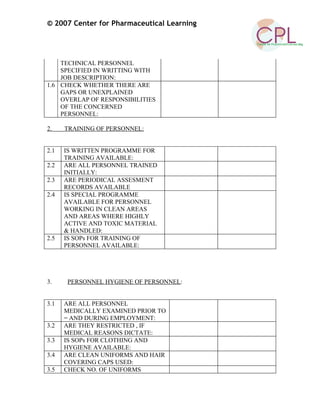

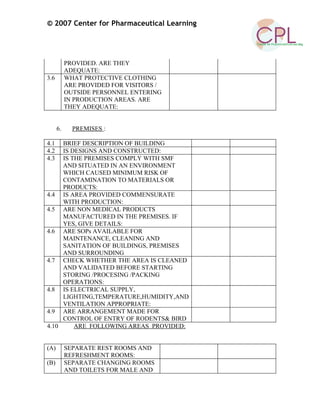

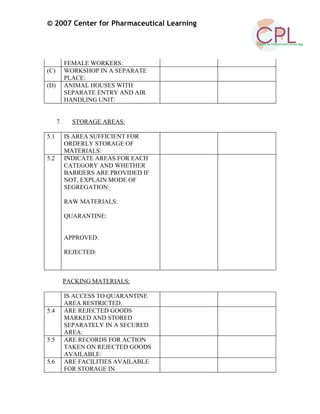

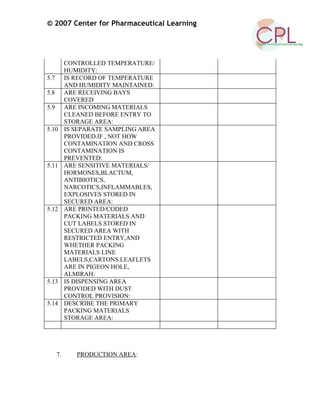

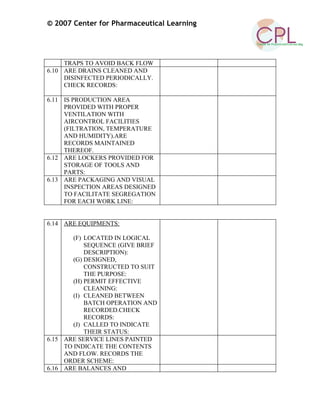

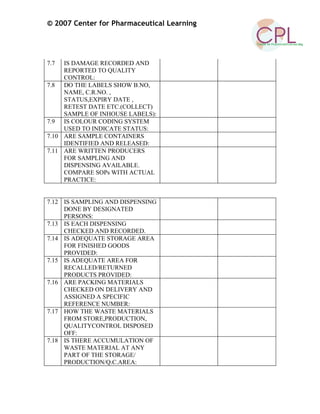

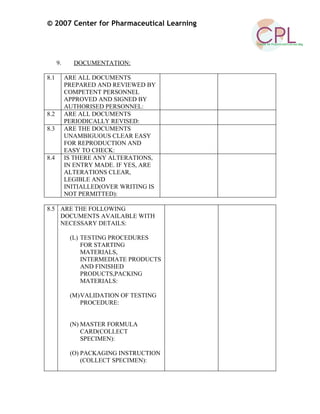

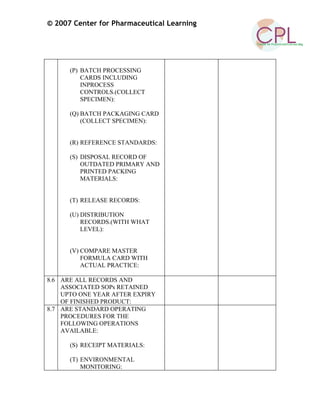

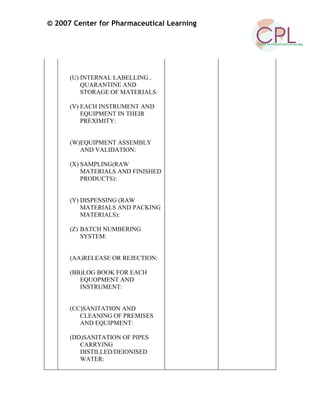

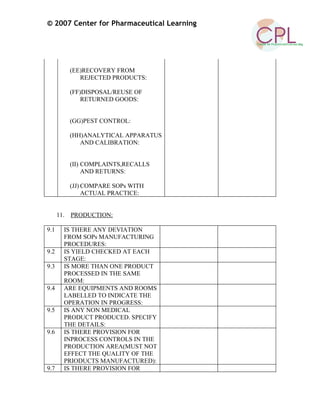

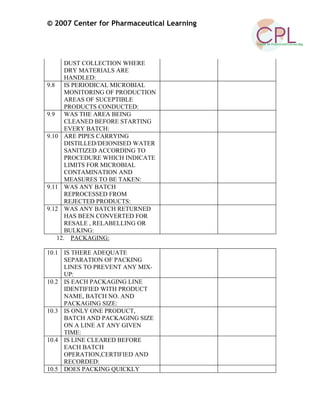

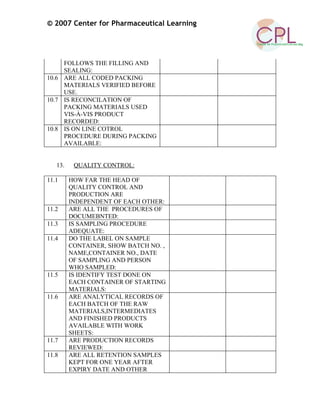

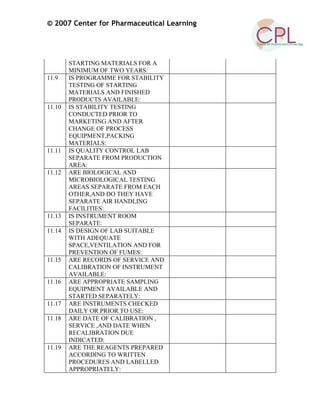

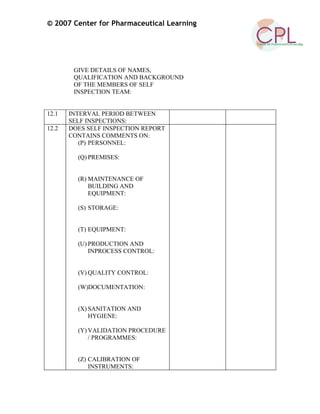

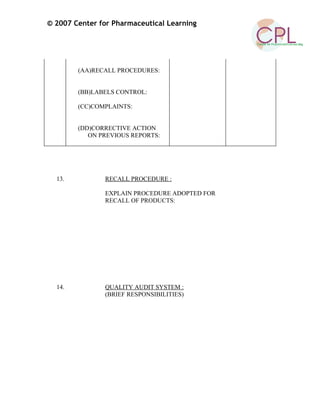

This document appears to be an inspection report form used by inspectors from the World Health Organization (WHO) to inspect pharmaceutical manufacturing firms and ensure compliance with Good Manufacturing Practices (GMP). The form includes sections to record details of the firm, personnel, facilities, equipment, materials, documentation, production processes, and compliance with GMP standards. Inspectors would use this form to systematically evaluate all aspects of the facility and operations during an inspection.