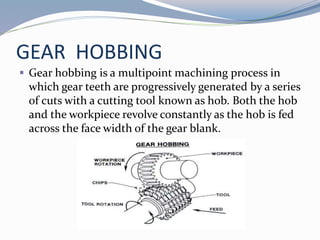

Gear hobbing is a machining process that uses a hob cutter to progressively cut gear teeth into a workpiece. The hob and workpiece rotate in a precisely timed relationship determined by change gears, with the hob making multiple cuts across the workpiece on each pass to form several teeth simultaneously. Indexing fixtures are used to rotate the workpiece incrementally between hobbing passes according to pre-determined divisions or degrees as needed to cut all teeth. The rotational relationship between the hob and workpiece is key to producing gears with the proper number of teeth.