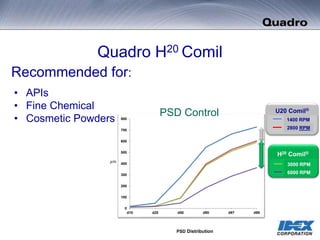

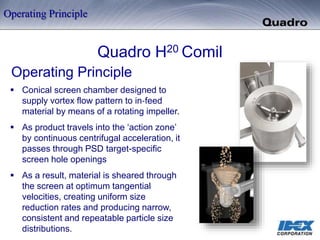

The Quadro H20 Comil is designed for controlled particle size reduction in APIs and fine chemicals, optimizing milling performance with superior energy conversion and narrow particle size distributions. Its unique benefits include improved on-target milling efficiency, reduced waste, and contained milling to minimize exposure to airborne contaminants. The Comil features a versatile design with various operational options and configurations to meet diverse milling needs.