This document investigates reducing uneven shade problems in compact single jersey cotton knit fabrics dyed with turquoise reactive dyes. Scanning electron microscopy shows that stripping and scouring combined increases fabric porosity compared to scouring alone, allowing better dye penetration. Color measurement testing finds that combining stripping and scouring results in more consistent dye absorption and less uneven shading than separate processes, with CMC ΔE values below 1 indicating acceptable color matches. In conclusion, performing stripping and scouring simultaneously on compact single jersey fabrics before dyeing with turquoise reduces uneven dyeing compared to conventional pretreatment methods.

![IOSR Journal of Polymer and Textile Engineering (IOSR-JPTE)

e-ISSN: 2348-019X, p-ISSN: 2348-0181, Volume 2, Issue 1 (Jan - Feb. 2015), PP 40-46

www.iosrjournals.org

DOI: 10.9790/019X-0214046 www.iosrjournals.org 40 | Page

Investigation of Reducing Process of Uneven Shade Problem In

Case Of Compact Single Jersey Cotton Knit Fabric with

Turquoise Color Reactive Dyes

MD. Ramij Howlader1

Mohammad Abul Hasan Shibly2

Ripon kumar Prasad3

MD. Tanjibul Hasan Sajib3

MD. Rafiqul Islam4

(Lecturer, Department of Textile Engineering, BGMEA University of Fashion & Technology, Bangladesh)

(Merchandiser, Orion Knit Textiles Limited, Bangladesh)

(Lecturer, Department of Textile Engineering, BGIFT Institute of Science & Technology, Bangladesh)

(Lecturer, (FDT), BGMEA University of Fashion & Technology, Bangladesh)

(Bangladesh University of Textiles)

Abstract: Most dyes do not chemically react with the cellulose molecule to affix the color. True chemical

reaction between cellulose and the dye molecule occurs with reactive dyes. But some of reactive colors such as

turquoise have definite properties which mostly yield even shade with the single jersey cotton fabric which GSM

ranges from 120 to 160. Because such fabrics having quite relatively compact structure that does not allow

proper penetration of dye molecules evenly into fiber polymer system. Due to those problems, the knit dyeing

factories in Bangladesh have been facing a lot of problems. In present days, these factories are practicing re-

dyeing like toping and stripping and dyeing. To solve this problem, the compact single jersey fabric may be

treated in different manner in the preparatory stage. The conventional pretreatment process involved scouring,

bleaching before dyeing. By using stripping process at preparatory stage may reduce uneven shade problem

during coloration of turquoise color of reactive dye.

Keywords - Compact Single Jersey, Grey Stripping, GSM, reactive dyes, Turquoise Color.

I. Introduction

The introduction of the paper should explain the nature of the problem, previous work, purpose, and the

contribution of the paper. A T-shirt (or T shirt, tee-shirt, or tee) is Reactive dyeing is now the most important

method for the coloration of cellulosic fibers. Reactive dyes have a low utilization degree compared to other

types of dyestuff, since the functional group also bonds to water, creating hydrolysis of Reactive Dye. Reactive

dyes have good fastness properties owing to the bonding that occurs during dyeing. Cotton is made of cellulose

molecules which react with the dye. During reactive dyeing the H atom in the cellulose molecule combines with

the Chlorine atom in the dyeing process and results in a bond. Tri-functional dyestuffs also exist [1].

Roll to roll shade variation always confused for matching the batch with standard shade and produces a

variety of shade within a batch. This is a result of mixing of fabric roll produced from different fiber lot, yarn

count, GSM, structure and even sometime for different machines. So to avoid such problems one has to avoid

mixing of different types of fabrics. Patchy is the real uneven dyeing; this may result of uneven absorbency,

electrolytes (salt) alkaline pH, uneven and sudden alkali dosing, wrong dye combinations, improper mixing of

dyes, improper neutralization after scouring-bleaching and dyeing, fabric entanglement during process etc. If

above mentioned points are under controlled then possibility of patchy is very low. It is the solution only for

batch to batch shade variation but uneven shade problem need to be considered in case of compact single jersey

fabrics. Color spot is the result of improper color mixing (very serious issue in case of turquoise dyes as their

dye molecules are comparatively larger), water hardness and presence of heavy metal sulphate, sulphides,

sulphites & alkali especially caustic soda. Water treatment plant, sequestering agent and proper mixing of dyes

are fundamental solution of this problem. White specks are mainly yarn problem i.e. dead or immature fibers.

Moreover contamination in water, improper dissolve of alkali and presence of silica based chemical before

dyeing also arise white spots. Excluding yarn quality; WTP, proper handling of caustic and de-finishing

removing silica based finishes, incase processing of finished fabric with such finishing chemicals, are necessary

to solve such problem. Only color spot can be removed by above this process but uneven shade problem may

not be reduced by using this process. So need to be considered solution for reducing uneven shade problem in

the knit fabric. Meter to meter shade variation is a typical shade variation problem. Very short dyeing arise

unleveled dyeing. Furthermore, it was found that, imbalance dosing time, run time and temperature gradient of

each step with cycle time of fabric is responsible for meter-to-meter shade variation. Six batches are dyed with

linear dosing system, in case of alkali & per-oxide dosing of scouring bleaching and dyes, salt, alkali of dyeing,

on this aspect and described in methodology and result section. By controlling proper addition of dyes,](https://image.slidesharecdn.com/g0214046-150625060352-lva1-app6891/75/Investigation-of-Reducing-Process-of-Uneven-Shade-Problem-In-Case-Of-Compact-Single-Jersey-Cotton-Knit-Fabric-with-Turquoise-Color-Reactive-Dyes-1-2048.jpg)

![Investigation of reducing process of uneven shade problem in case of compact single jersey…

DOI: 10.9790/019X-0214046 www.iosrjournals.org 41 | Page

electrolytes, and alkali dosing, meter to meter shade variation can be removed but random uneven shade

problem may be minimized by adopting grey fabric stripping process in the compact single jersey [1].

Roll to roll shade variation, patchy dye, color spot could be minimized by controlling knitting process,

dyeing parameter etc. but uneven shade problem may be minimized by grey fabric stripping before dyeing. Due

to the compactness of the fabric structure dye molecules may not penetrate into the cotton fiber core. Stripping

may reduce the compactness of the fabric as well as increase the size of the porosity of cotton fiber so that the

dye molecules may enter the fiber polymer system. So stripping may be performed in the gray fabric to reduce

such type of problem. It may be the latest concept to remove uneven shade problem in case compact single

jersey with reactive turquoise colorants.

II. Materials

2.1 Material used

Compact single jersey cotton fabric

Single jersey fabrics are based on plain structure used to produce fully fashioned knitwear. Plain is a knit

structure family, which is produced by the needles of only one set needle with all the loops intermeshed in the

same direction. Although plain knit family encompasses a great number of structures all produced on single

needle bed. The basic element of knit fabric structure is the loop intermeshed with the loops adjacent to it on

both sides and above and below it [2].

Turquoise color reactive dyes

In 1954, dyes were discovered which containing dichlorotriazinyl group could be applied from aqueous solution

and caused to form a covalent bond with cellulose by increasing the pH. This discovery resulted in the first

commercial reactive dyes for cellulose, the procion dyes, being marketed in 1956 [3].

Hydrose

Custic soda

Hydrosen peroxide

Sequestering agent

Detergent

Sodium carbonate etc.

III. Different Process/Method

3.1 Scouring process

Scouring is performed to remove any impurities present in the fabric. The impurities (i.e. oil & wax,

lubricants, dirt, surfactants, residual tints) are removed using an alkaline solution, typically sodium hydroxide, at

high temperatures to breakdown or emulsify and saponify impurities.

Recipe

Fino wet-OSR (Detergent) : 1 gm/L

Caustic soda : 5 gm/L (Dosing at 600

C for 10 min)

Albafluid C (Anti-creasing) : 1 gm/L

Arboquest 340 (Sequestering) : 0.5 gm/L

Time : 40 min

Temperature : 900

C

Neutralization

Acetic acid : 1 gm/L

Time : 10 min

Temperature : 600

C

3.2 Stripping and scouring combined process

Place illustrations the gray compact single jersey cotton fabric has been subjected to scouring and

stripping process for removal natural impurities such as wax, pectin, fat, oil etc from cotton fibers. Here

scouring and stripping was carried out by using suitable recipe with maintaining proper time and temperature.

After treatment the fabric was washed off two times i.e. hot wash and cold wash and then dried.

Recipe

Fino wet-OSR (Detergent) : 1 gm/L

Caustic soda : 5 gm/L (Dosing at 600

C for 10 min)

Hydrose : 6 gm/L (Dosing at 800

C for 10 min)

Albafluid C (Anti-creasing) : 1 gm/L

Arboquest 340 (Sequester) : 0.5 gm/L

Time : 40 min

Temperature : 900

C](https://image.slidesharecdn.com/g0214046-150625060352-lva1-app6891/75/Investigation-of-Reducing-Process-of-Uneven-Shade-Problem-In-Case-Of-Compact-Single-Jersey-Cotton-Knit-Fabric-with-Turquoise-Color-Reactive-Dyes-2-2048.jpg)

![Investigation of reducing process of uneven shade problem in case of compact single jersey…

DOI: 10.9790/019X-0214046 www.iosrjournals.org 42 | Page

Neutralization

Acetic acid : 1 gm/L

Time : 10 min

Temperature : 600

C

3.3 Dyeing method

Reactive dyes can be applied by a conventional batch wise dyeing method for cellulosic materials. Dye

auxiliaries were taken into the dye bath along with the samples. Then the dye solution was poured into the dye

bath for absorption that was carried out by the gluber salt and migration was done at 800

C for 30 min. Finally

sodium carbonate was dosed at 500

C for 20 min for fixation. Then the dyed samples were neutralized, hot

washed and cold washed.

Recipe

GSS (Leveling agent) : 0.12 gm/L

Arboquest 340 (Sequester) : 1 gm/L

Albafluid C (Anti-creasing) : 1 gm/L

Glauber salt : 35 gm/L

Reactive Turquoise Blue H2GP : 2.52%

Reatobond Blue RR : 0.06%

Indofix yellow ME4GL : 0.64%

Sodium carbonate : 15 gm/L (at 500

C for 20 min.)

Time : 30 min

Temperature : 600

C

Cold wash

Acetic acid : 1.5 gm/L

Time : 15 min

Temperature : 400

C

Hot wash

Jintex (Detergent) : 1 gm/L

Time : 20 min.

Temperature : 900

C

Cold wash

Time : 10 min.

Temperature : 400

C

3.4 Scanning electron microscopy (SEM) test

The characterization of textile materials has employed many microscopic techniques such as optical

and electron microscopy. Scanning electron microscopy (SEM) uses electrons rather than light to form an

image. An SEM can produce high resolution and depth of field of images, and provides useful tools for

examining structural and surface characteristics of textile materials. The specimen to be observed in the SEM

must remain at a constant potential during examination. Specimens that are not naturally conductive have to be

coated with a thin layer of a conductive material. A development in electron microscopy in the form of an

ESEM opens up new possibilities for textile research. In the ESEM, specimens can be hydrated or dehydrated

by controlling the temperature of the specimens and the chamber pressure in favor of water condensation or

evaporation at different relative humidity. The SEM is specifically suited to dynamic experimentation of the

micron scale and below. SEM technology allows dynamic experiments at a range of pressures, temperatures and

under a variety of gases/fluids. Some accessories can also be added into an SEM to expand its observation

capacity for characterizing textile materials. The SEM is able to physically examine virtually any textile

materials without any special preparation or conductive coating. [4].

Rapid, high resolution imaging with identification of elements present. Spatially resolved quantitative

EDX (EDA) analysis of user defined areas on sample surface. Characterization of particulates and defects.

Examination of grain structure and segregation effects. Coating thickness measurement using cross sectional

imaging of polished sections.

Fig.1: Scanning Electron Microscope tester](https://image.slidesharecdn.com/g0214046-150625060352-lva1-app6891/75/Investigation-of-Reducing-Process-of-Uneven-Shade-Problem-In-Case-Of-Compact-Single-Jersey-Cotton-Knit-Fabric-with-Turquoise-Color-Reactive-Dyes-3-2048.jpg)

![Investigation of reducing process of uneven shade problem in case of compact single jersey…

DOI: 10.9790/019X-0214046 www.iosrjournals.org 43 | Page

3.5 CMC value measurement

The color of an object depends on the relative quantity of the light reflected or transmitted at different

wavelengths within the visible range (400-700 nm). Spectrophotometric measurements provide the numerical

description of the reflection or transmission of light by an object. The reflection or transmission spectrum gives

the fraction of the incident light that an object reflects or transmits as a function of wavelength. For color

measurement on textiles correct sampling is important.

The result was analyzed by a CIELAB color system. CIE (Commission Internationale de I’Eclairage)

color coordinates include color qualities in terms of L* (lightness and darkness), a* (redness and greenness), b*

(yellowness and blueness), C* (chroma) and H (hue angle, the angle of the anticlockwise movement from an

axis of +a* direction, that is, +a*=00, +b*=900, -a*=1800, and –b*= 2700). The ΔE values of differently dyed

fabrics. ΔE value contains the information of color depth, shade, and the hue of a sample [5]. ΔE value is

calculated by using the CIE L*, a*, and b* values with the equation;

ΔE = (ΔL*2 + Δa*2 + Δb*2)1/2

where ΔL*, Δa*, and Δb* values were the difference between L*, a*, and b* values of a pair of color standard

and sample.

The values of C* and H are calculated from a* and b* as;

C* = (a*2 + b*2)1/2

H = tan-1(b*/a*)

The larger the ΔE value, the greater would be the color difference between this pair of color standard and

sample. The experiment was carried out under light source of D 65 at 100 and the outputs showed satisfactory

results remarked as “pass” for pairs of samples having a value of CMC DE value less than 1.00 will be an

acceptable match.

3.6 K/S value measurement

Colorant formulation procedures for spectrophotometric matching use the Kubelka–Munk equation

relating the absorption and scattering coefficients and the concentrations of the colorants in the sample with its

overall reflectance [5]. The global Kubelka–Munk K/S value at a given wavelength is:

K/S = (1-R) 2/2R

Where K and S are the respective values of the absorption and scattering coefficients of the various dyed and of

the undyed textile materials. R is the reflectance of a sample of fabric that is sufficiently thick to prevent light

transmission through it.

IV. Results And Discussions

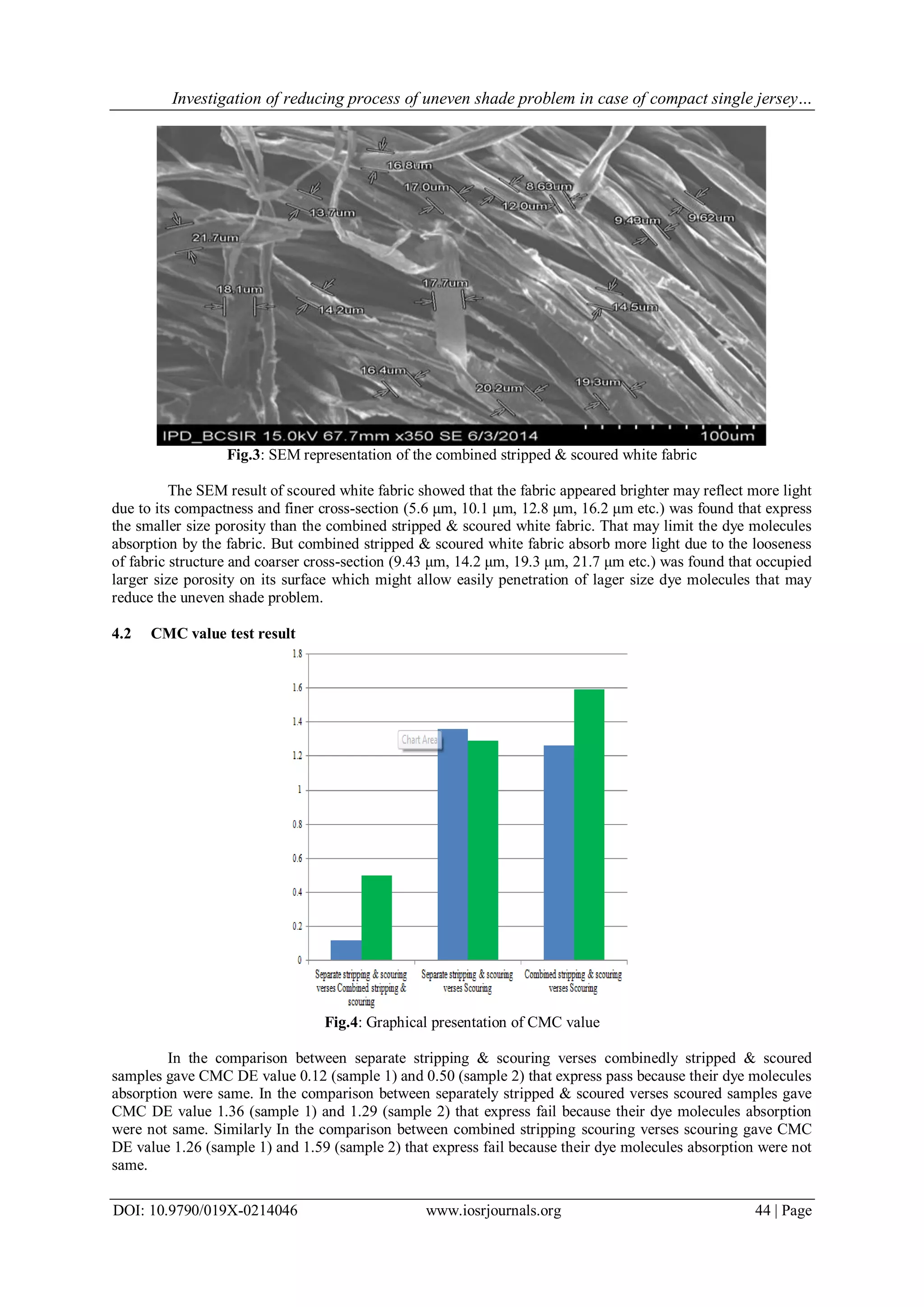

4.1 SEM result

Following mention the pictorial representation of scoured white fabric and combined striped & scoured fabric

surface structure.

Fig.2: SEM representation of the scoured white fabric](https://image.slidesharecdn.com/g0214046-150625060352-lva1-app6891/75/Investigation-of-Reducing-Process-of-Uneven-Shade-Problem-In-Case-Of-Compact-Single-Jersey-Cotton-Knit-Fabric-with-Turquoise-Color-Reactive-Dyes-4-2048.jpg)

![Investigation of reducing process of uneven shade problem in case of compact single jersey…

DOI: 10.9790/019X-0214046 www.iosrjournals.org 46 | Page

Reference

[1] Moin, C. J., & Mahabubuzzaman, A. (2006). Process For Level Dyeing Of 100% Cotton Knit Fabrics With Reactive Dye.

[2] Spencer, D. J. (2001). Knitting Technology: A Comprehensive Handbook And Practical Guide (Vol. 16). Crc Press.

[3] Ahmed, A. I. (1995). Reactive Dyes Development: A Review. Textile Dyer And Printer, 28, 19-24.

[4] Broadbent, A. D. (2001). Basic Principles Of Textile Coloration (Vol. 132). West Yorkshire: Society Of Dyers And Colorists.

[5] Standard, A. S. T. M. (2008). Standard Practice For Conditioning And Testing Textiles. Astm International, West Conshohocken,

Pa.](https://image.slidesharecdn.com/g0214046-150625060352-lva1-app6891/75/Investigation-of-Reducing-Process-of-Uneven-Shade-Problem-In-Case-Of-Compact-Single-Jersey-Cotton-Knit-Fabric-with-Turquoise-Color-Reactive-Dyes-7-2048.jpg)