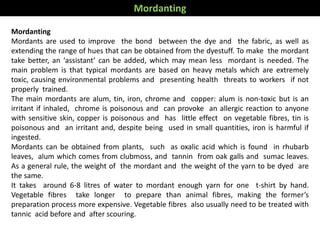

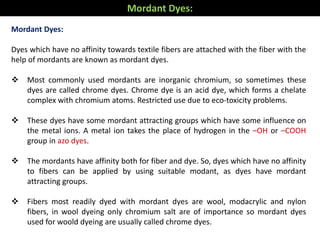

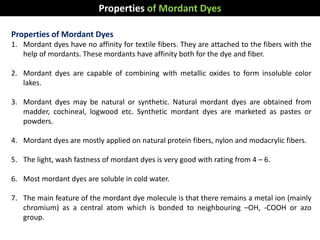

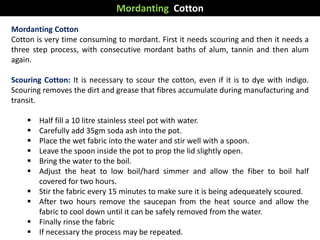

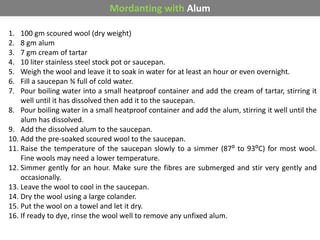

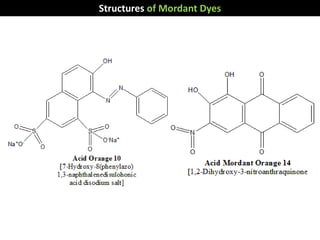

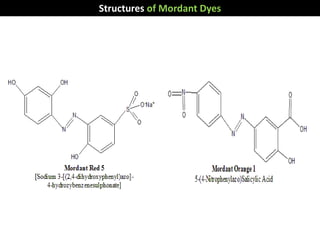

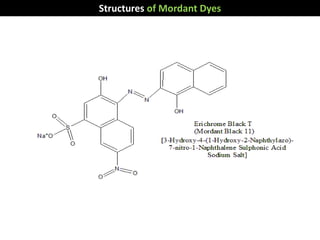

1. Mordants are chemical binding agents that help dyes adhere to fabrics by forming coordination complexes between the dye and the mordant, which then attaches to the fabric.

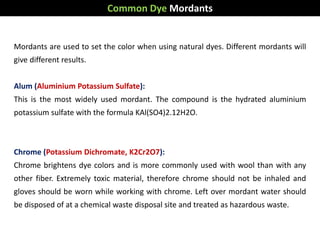

2. Common mordants include alum, tin, iron, chrome, and copper, though some can be toxic. Mordants are used before, during, or after dyeing to improve color fastness.

3. Different mordants will produce different dye colors; some darken hues while others brighten them. Proper mordanting is important for vibrant, long-lasting colors from natural dyes.