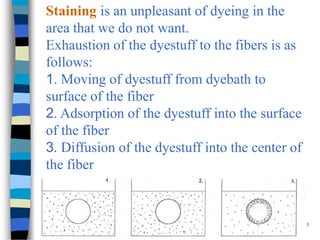

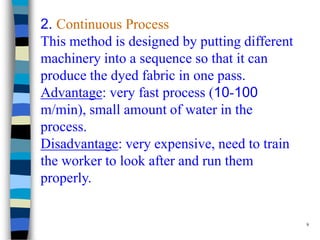

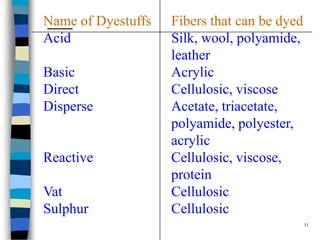

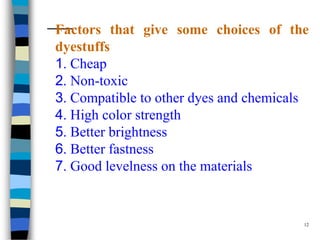

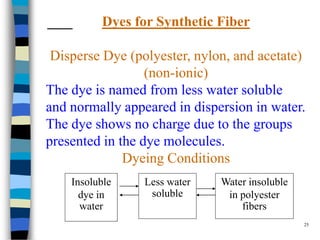

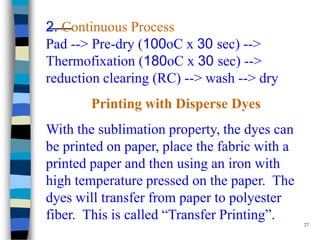

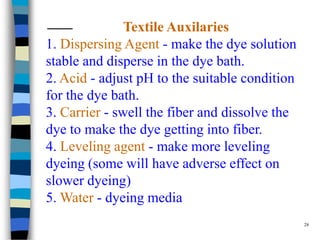

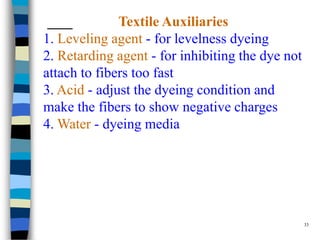

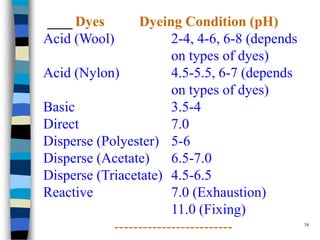

The document provides an introduction to textile dyeing, including definitions of basic terms like dyestuff and pigment, an overview of dyeing processes and factors that influence dye choices, and descriptions of different types of dyes including direct dyes for cellulosic fibers, reactive dyes, vat dyes, sulfur dyes, and disperse dyes for synthetic fibers. Classification methods for dyes and dyeing conditions for various fiber and dye combinations are also outlined.