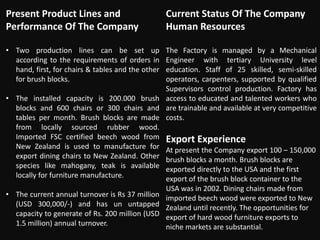

The company was established in 2000 to manufacture and export hardwood furniture and brush blocks. It operates a 20,000 square foot factory located in an export processing zone 50km from Colombo, Sri Lanka, and has space to expand to 60,000 square feet. The company seeks investors to inject capital and transfer technology to utilize local wood resources and craftsmanship to produce furniture for export markets like Europe, North America, and Asia. Current annual turnover is $300,000 with capacity for $1.5 million annually by expanding production lines and exports.

![[FURNITURE MANUFACTURING FACILITY]

The Company was established in the year

2000 to manufacture hard wood furniture and

brush blocks for export. The Company invites

local/ foreign investors to inject capital and

transfer modern furniture production

technology to convert the limited but valuable

tropical wood resources in Sri Lanka to

exportable finished products .

The Company was established in the year

2000 to manufacture hard wood furniture and

brush blocks for export. With experience in

the wood working industry and inspired by a

century old rich heritage of local craft skills

and entrepreneurial traditions we saw an

opportunity to set up a factory to combine

the modern with the traditional, offering

opportunities to our local craftsmen,

carpenters and locally grown teak, mahogany

to reach world markets.](https://image.slidesharecdn.com/furnituremanufacturing-140119015221-phpapp02/85/Furniture-Manufacturing-2-320.jpg)