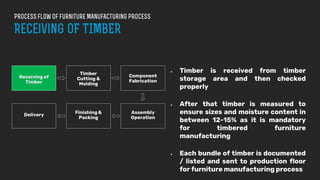

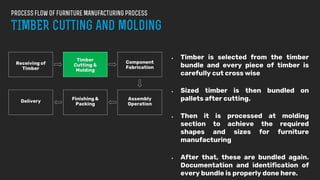

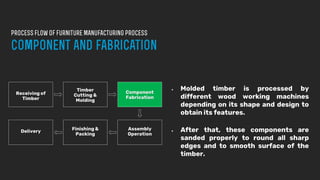

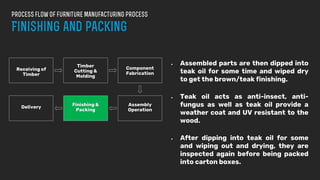

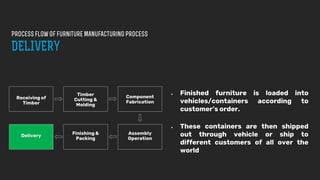

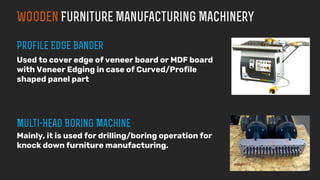

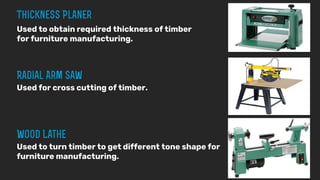

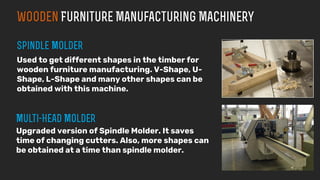

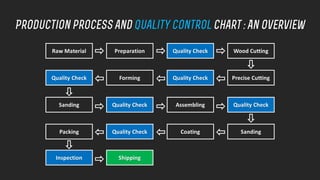

The document describes the furniture manufacturing process. Key steps include receiving timber, measuring and cutting it, molding pieces to required shapes, assembling components, finishing with teak oil, inspecting, and shipping the finished furniture to customers worldwide. Furniture provides movable objects to make rooms more comfortable for sitting, function, and decoration.