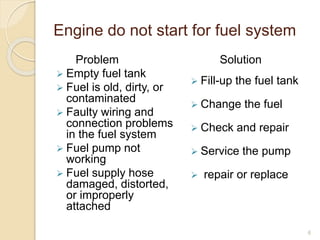

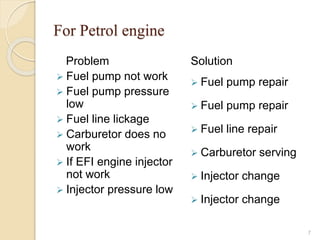

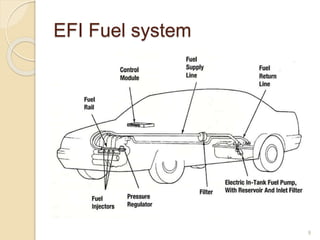

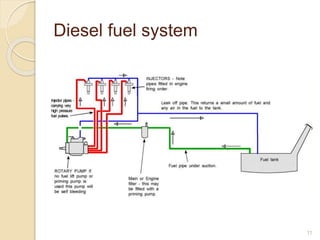

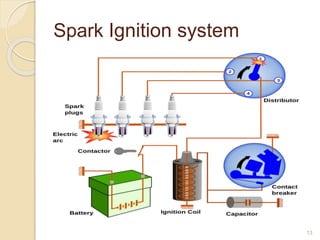

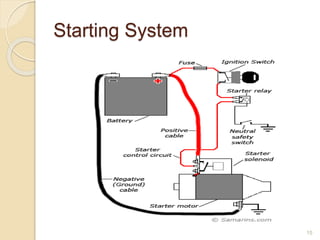

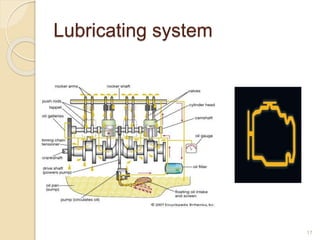

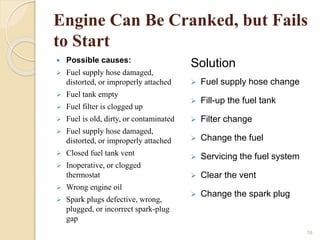

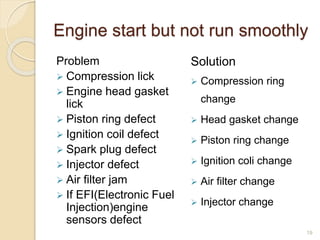

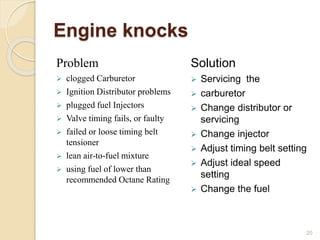

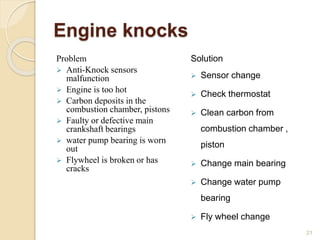

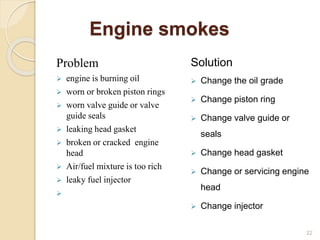

The document summarizes common problems with internal combustion engines and their solutions. It discusses issues that can prevent an engine from starting such as problems with the fuel system, ignition system, starting system, or lubrication system. Specific issues mentioned include empty fuel tanks, faulty wiring, non-working fuel pumps, weak batteries, and defective spark plugs. The document also covers problems that cause engines to run poorly such as compression leaks, worn piston rings, or ignition coil defects. Common causes of engine knocking and smoking are also listed along with recommended solutions.