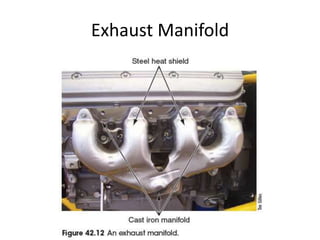

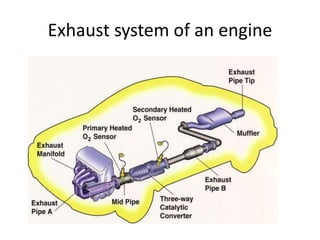

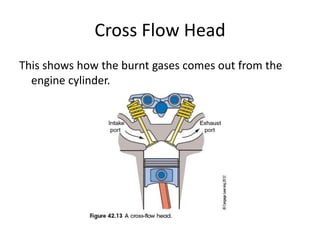

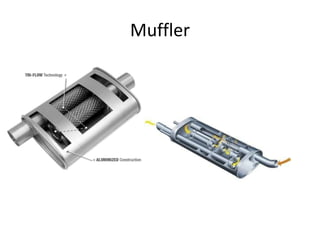

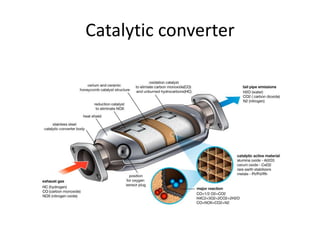

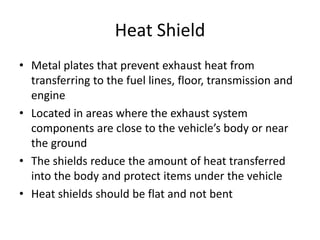

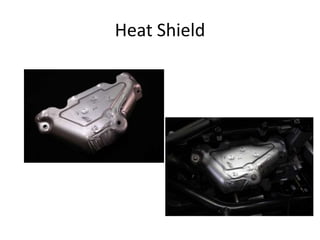

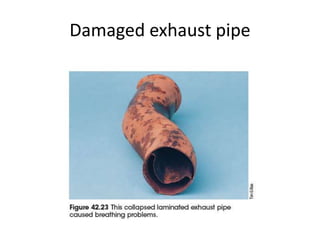

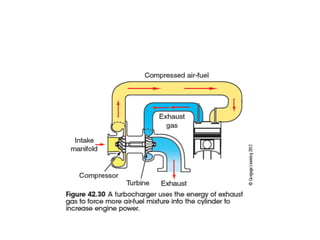

The document provides a comprehensive overview of an engine's exhaust system, including components like mufflers, catalytic converters, and turbochargers, detailing their function and operation. It highlights the role of the exhaust system in managing emissions, reducing noise, and enhancing engine performance. Additionally, the document addresses the importance of service and maintenance to prevent issues such as rust and backpressure.