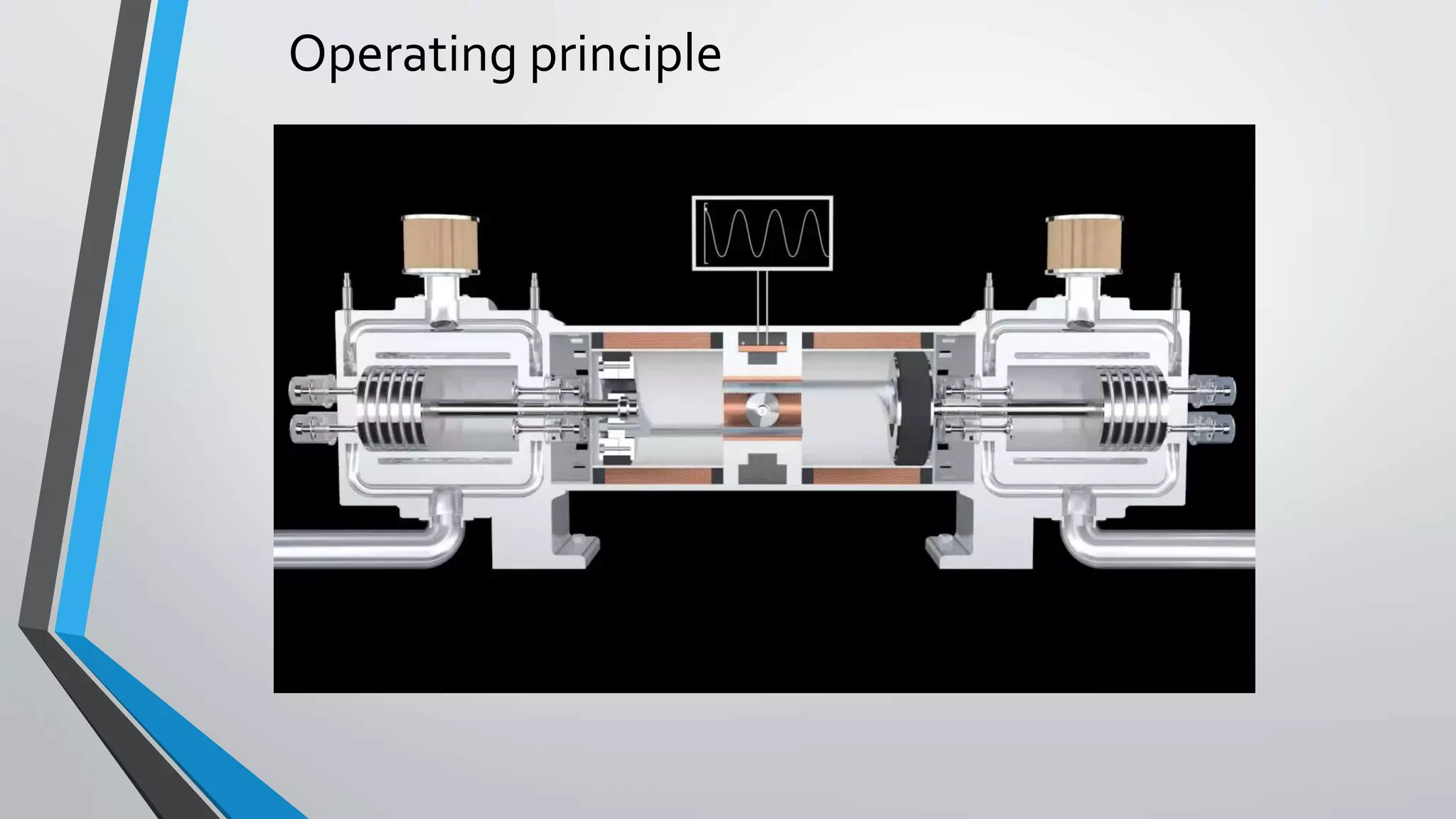

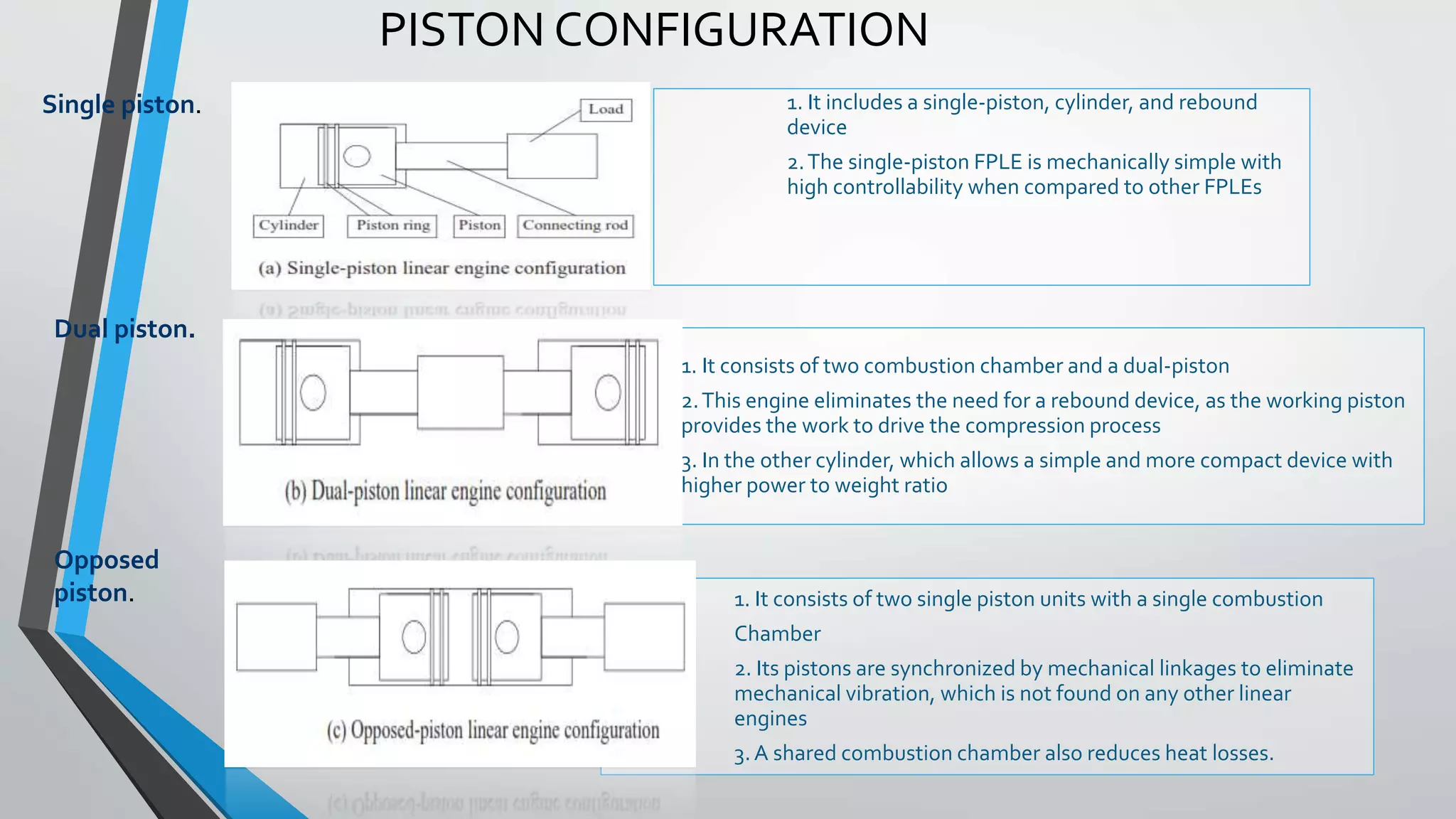

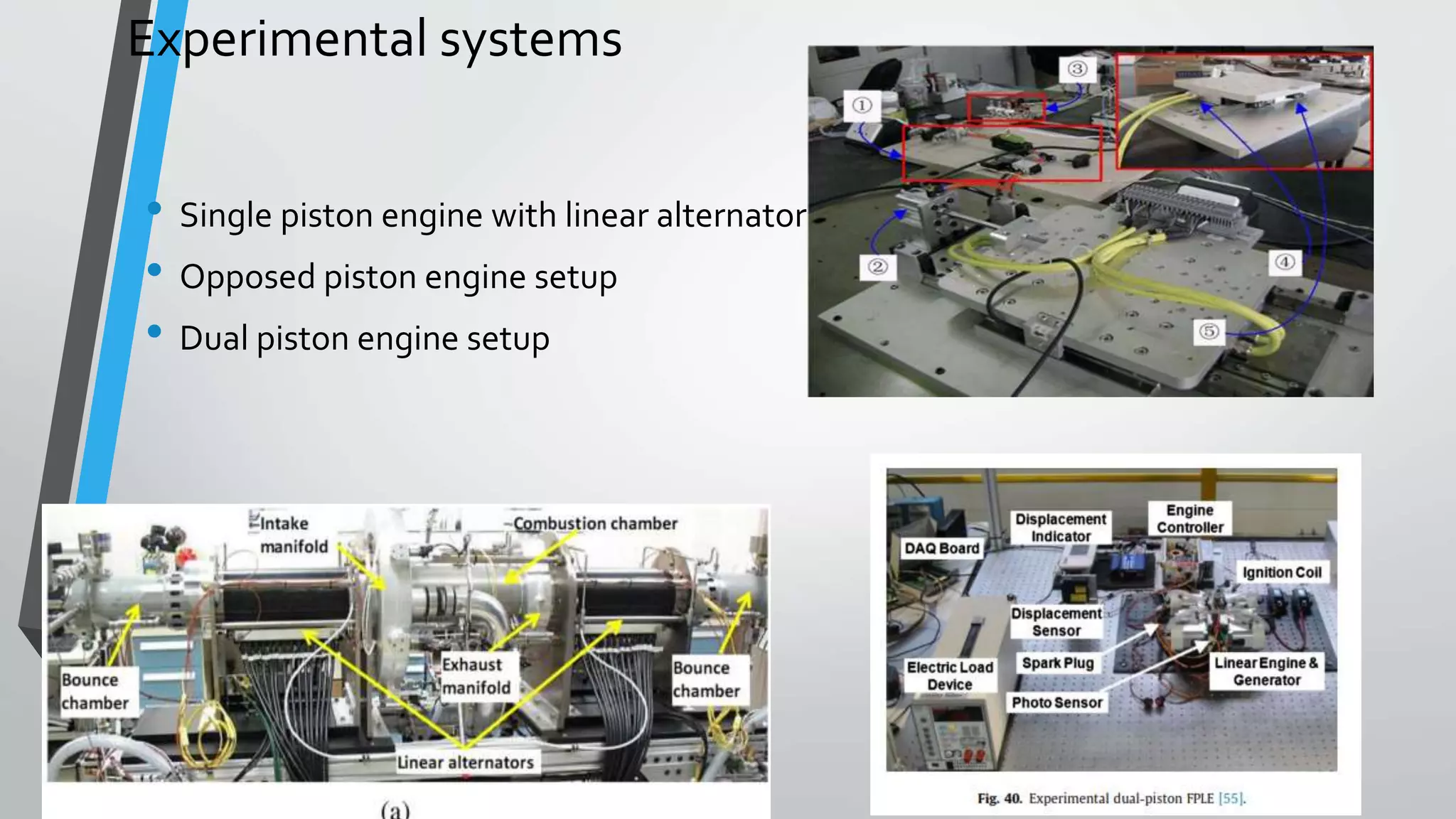

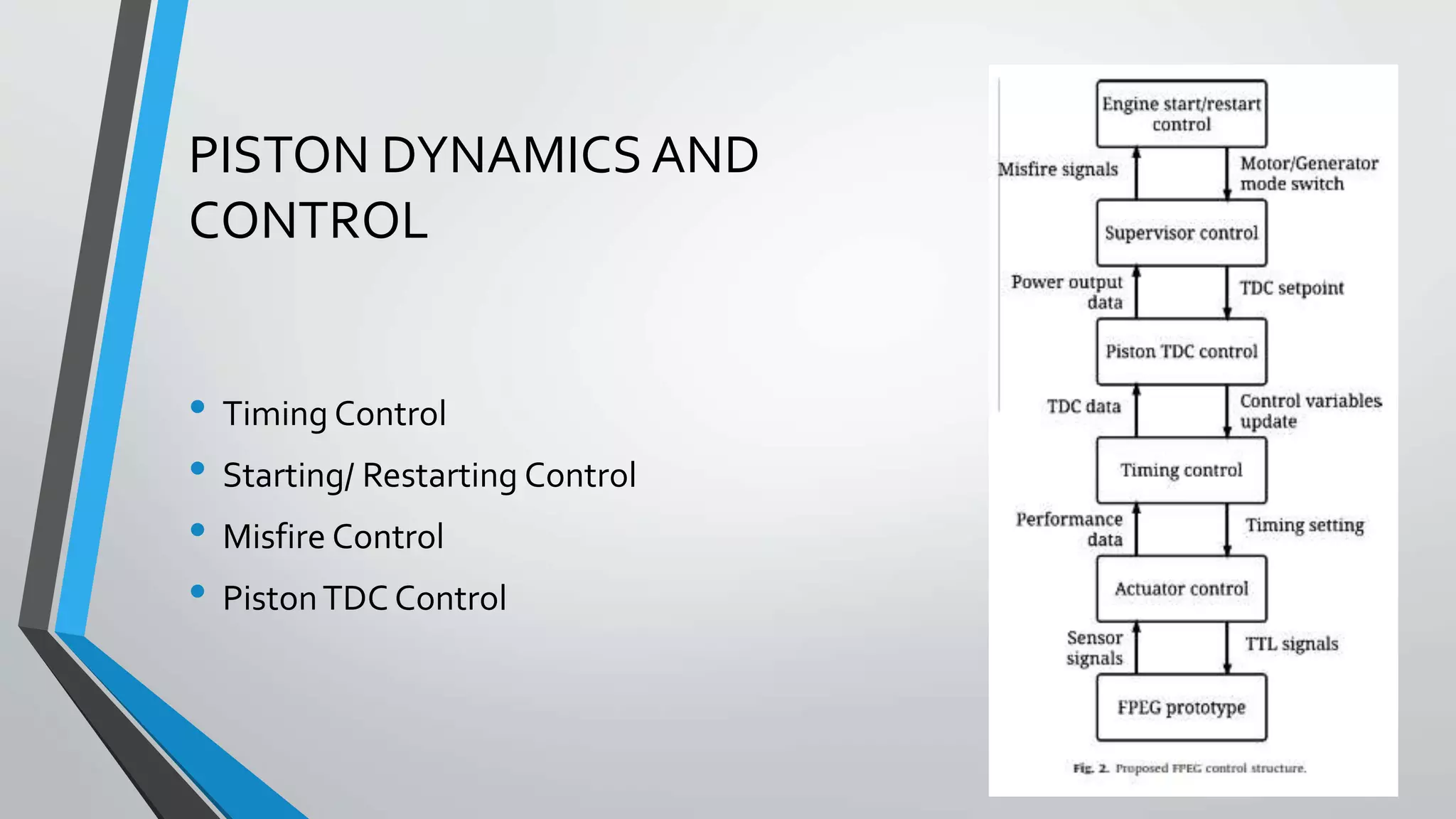

This document provides an overview of a review on free piston linear engines (FPLEs) and their control systems. It discusses the basics of FPLEs, including their operating principle and various piston configurations like single piston, dual piston, and opposed piston. It also describes experimental setups used to test FPLEs. Additionally, it covers piston dynamics and control topics like timing control, starting/restarting control, and misfire control. Applications of FPLEs discussed include improvements to efficiency, emissions reductions, and use in hybrid electric vehicles. The conclusion summarizes that two-stroke FPLEs are most commonly investigated due to advantages in structure and control.