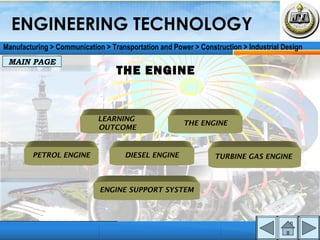

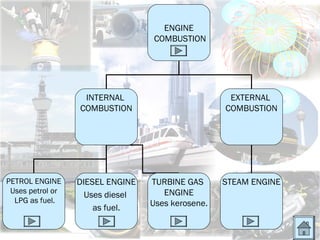

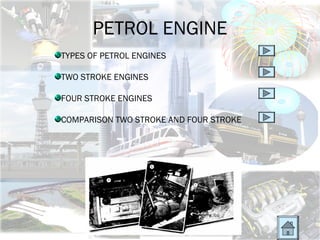

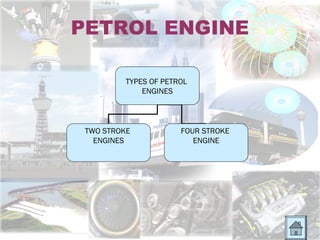

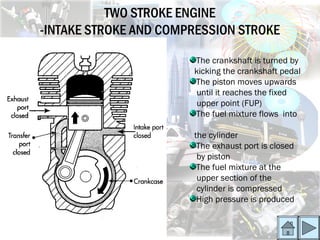

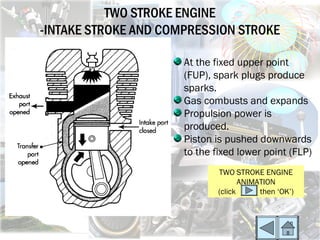

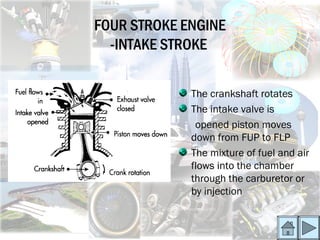

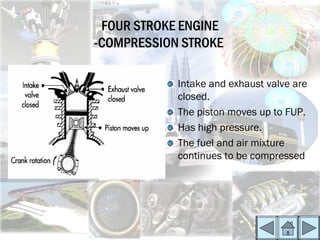

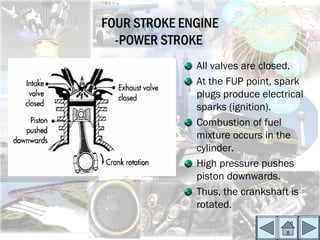

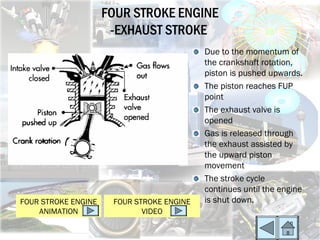

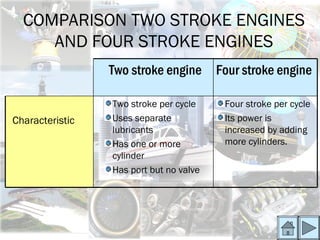

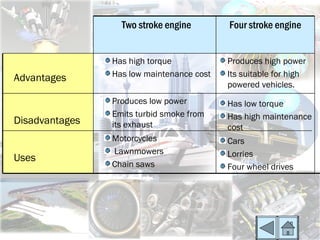

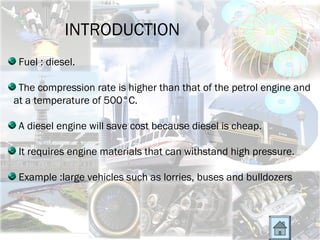

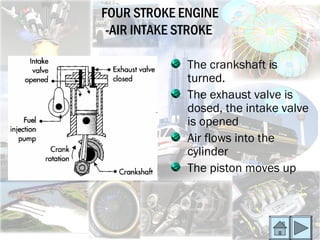

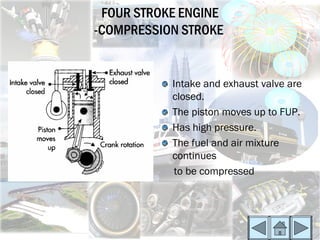

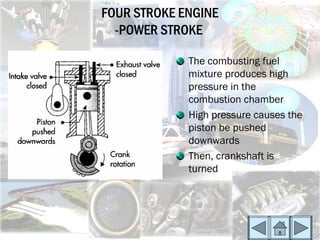

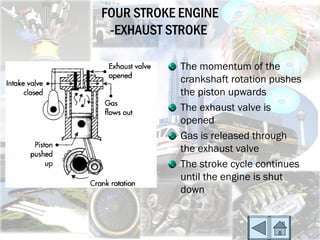

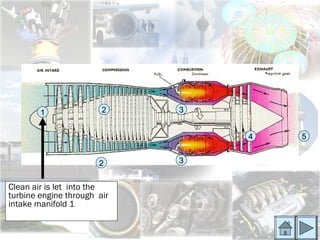

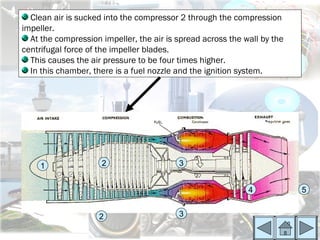

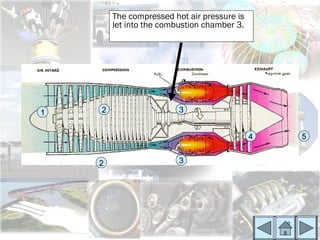

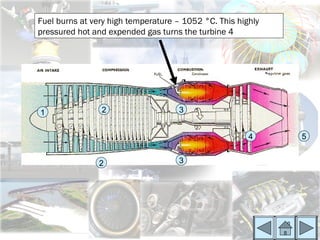

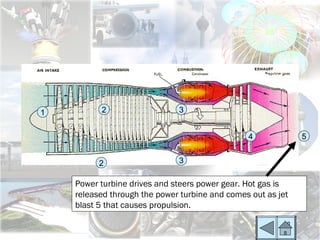

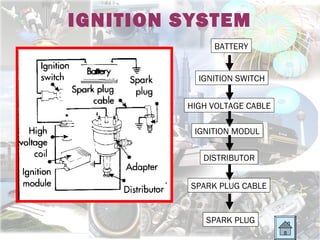

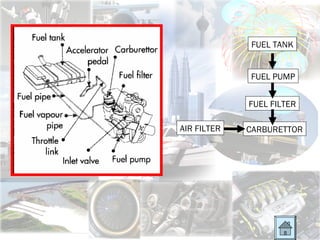

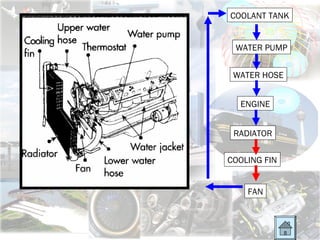

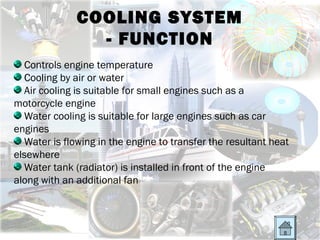

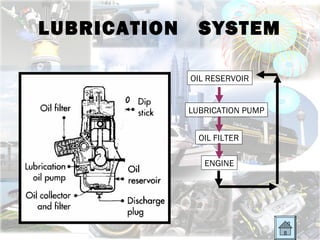

This document provides information about various types of engines. It discusses internal combustion engines like petrol engines and diesel engines. It explains the basic operating principles of 2-stroke and 4-stroke petrol engines. It also describes diesel engines and turbine gas engines. Additionally, it covers the main engine support systems, including ignition, fuel, cooling, and lubrication systems. The key components of each system are identified and their basic functions are explained.