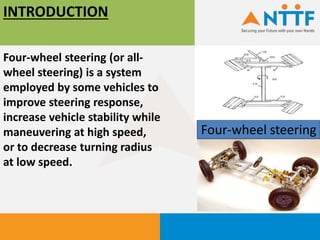

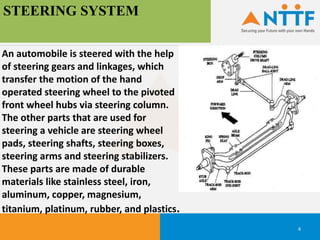

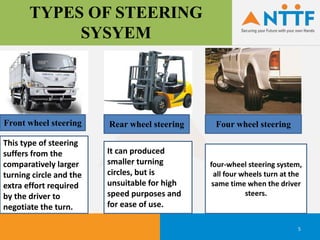

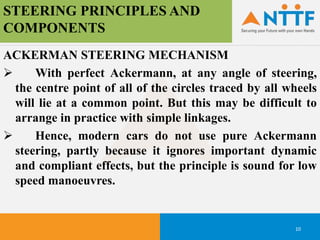

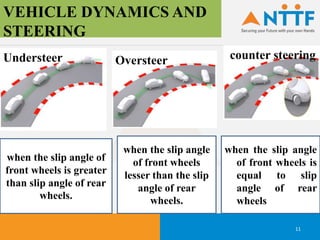

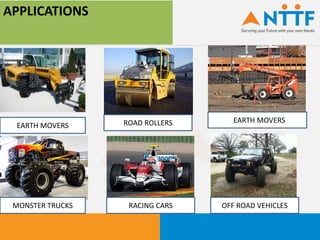

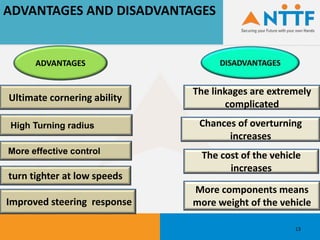

This technical presentation describes the four-wheel steering (4WS) system, which enhances vehicle stability and maneuverability. It details the working principle, wherein all four wheels turn simultaneously to improve turning radius at lower speeds, while discussing the components and advantages such as improved steering response. However, challenges include complexity and increased vehicle weight, and the design aims to optimize both maneuverability and stability.