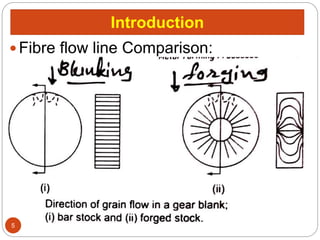

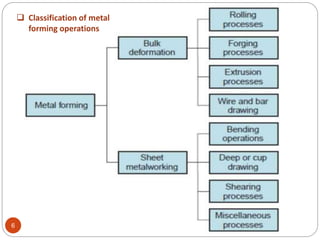

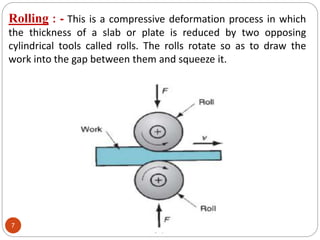

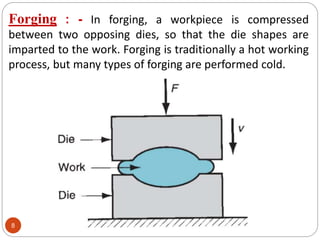

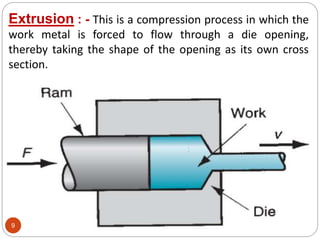

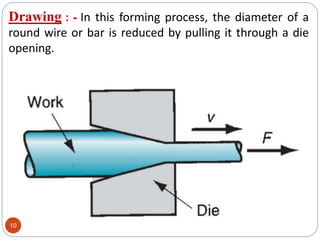

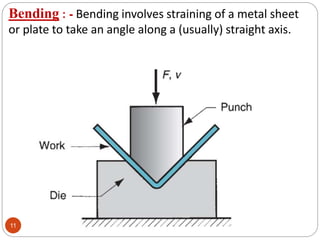

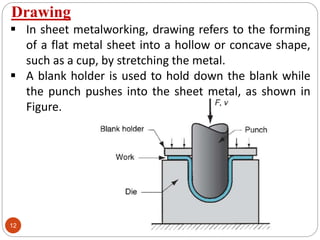

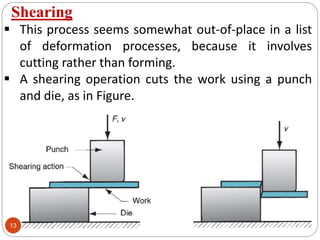

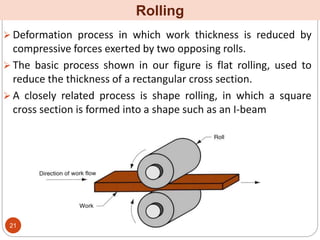

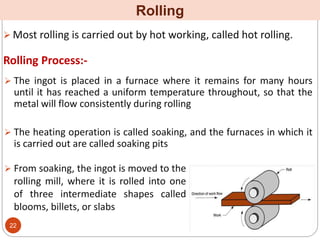

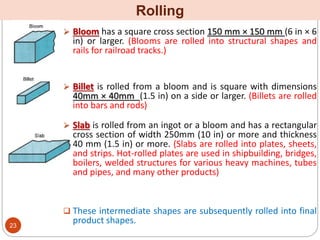

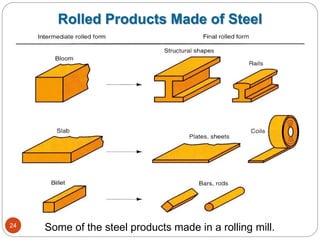

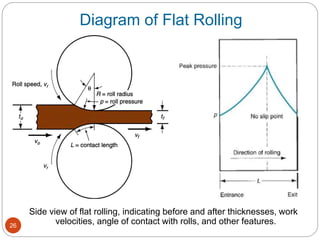

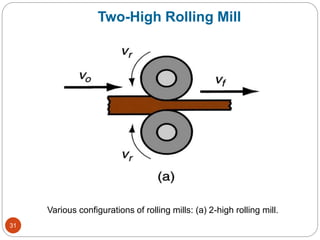

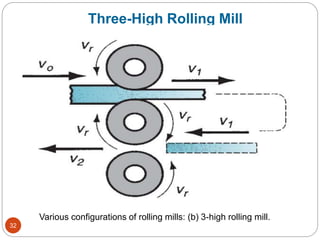

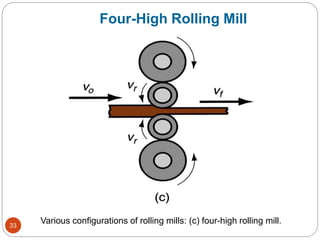

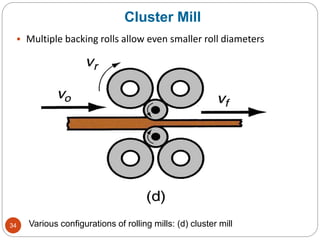

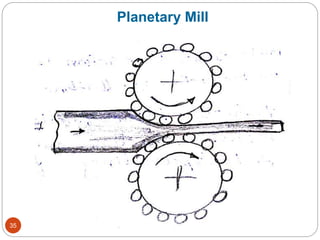

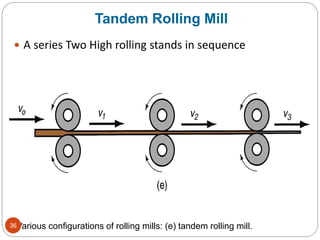

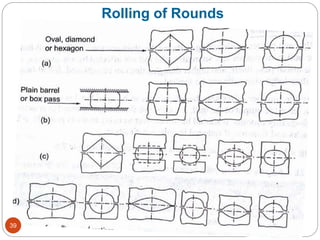

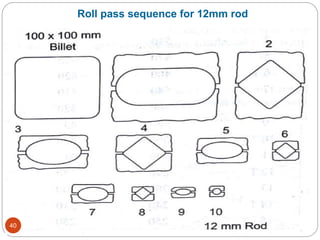

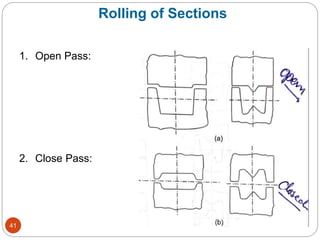

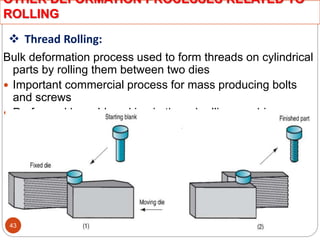

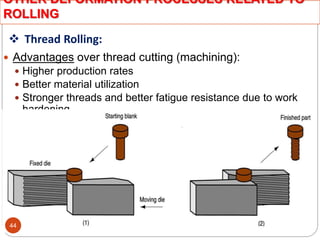

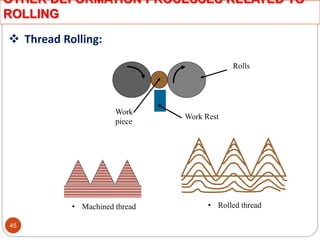

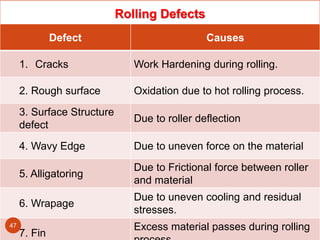

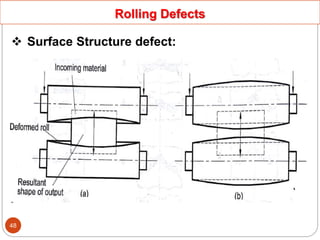

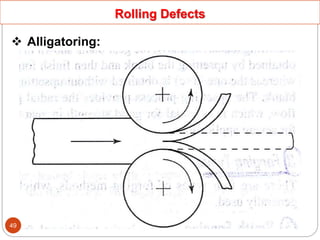

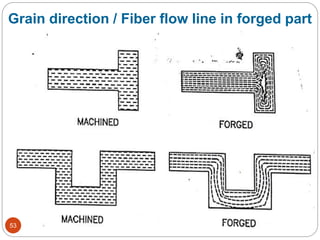

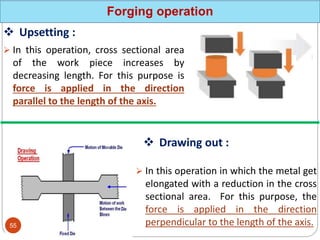

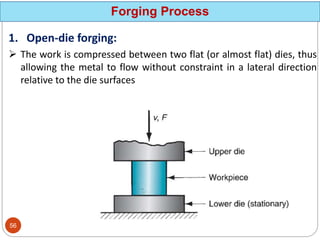

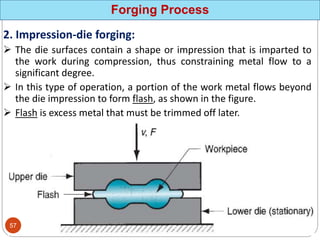

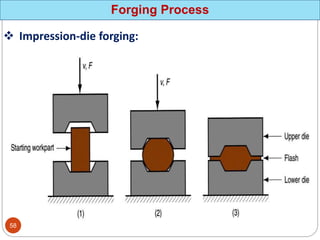

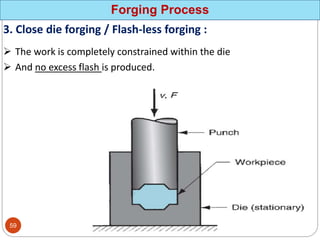

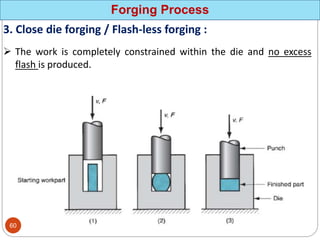

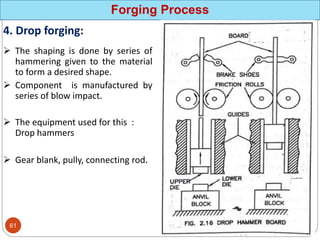

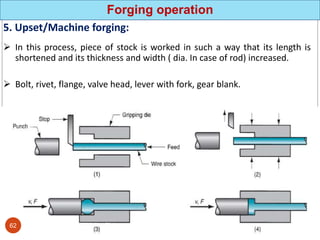

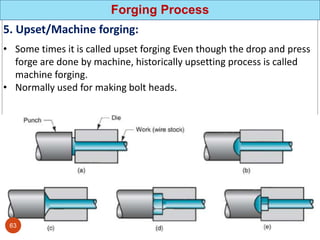

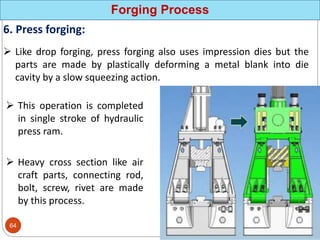

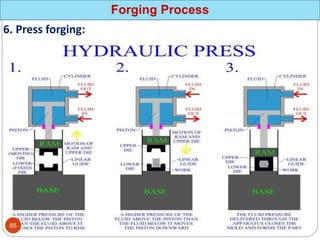

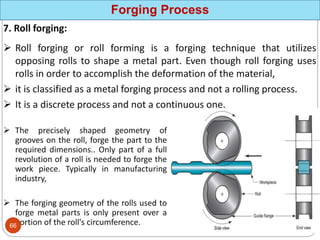

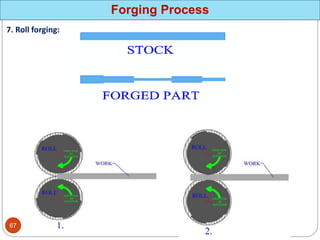

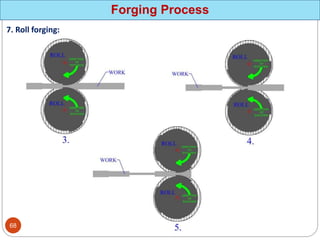

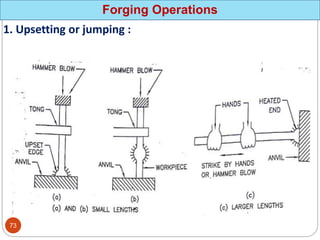

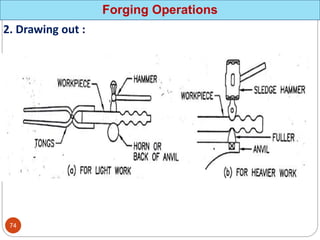

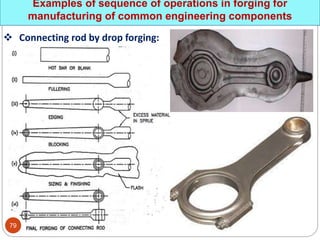

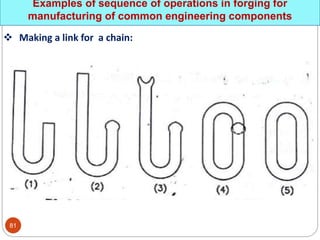

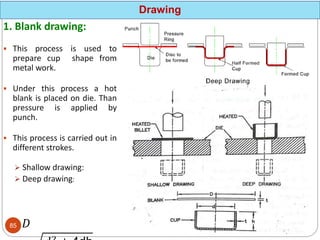

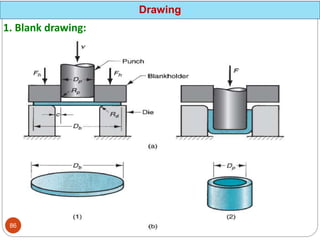

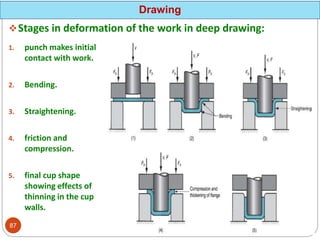

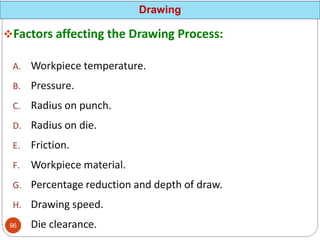

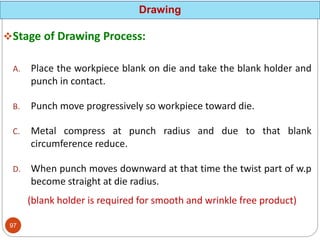

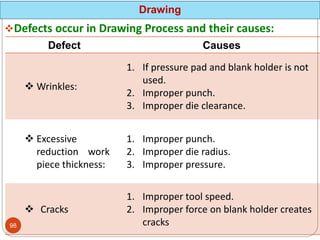

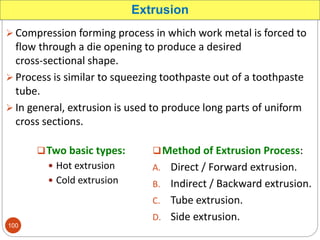

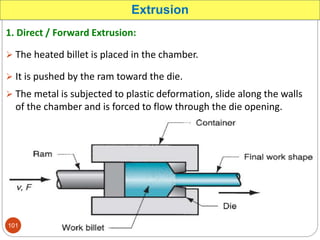

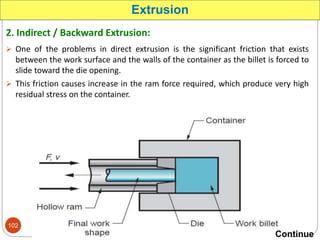

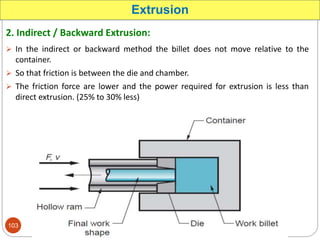

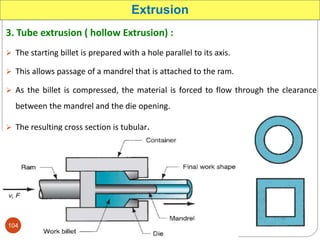

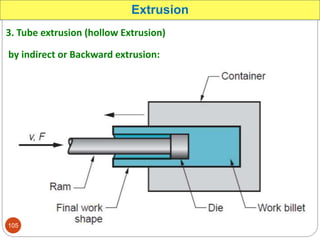

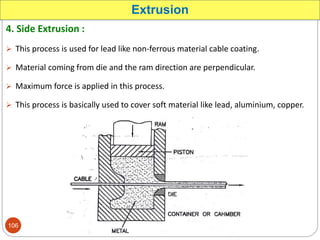

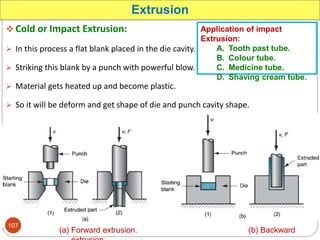

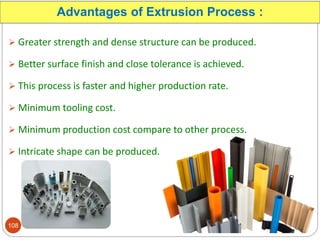

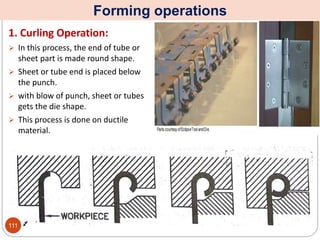

The document provides a detailed overview of various metal forming processes, including rolling, forging, extrusion, drawing, bending, and shearing, along with their advantages and disadvantages. It discusses the significance of temperature and material properties in these processes, as well as the classifications and specific techniques used in forging and rolling. Additionally, it highlights the applications, defects, and operational sequences involved in forging, and the importance of achieving precision in metal deformation.