1. Canning involves hermetically sealing food in containers, applying heat to sterilize the contents, and cooling for long-term storage.

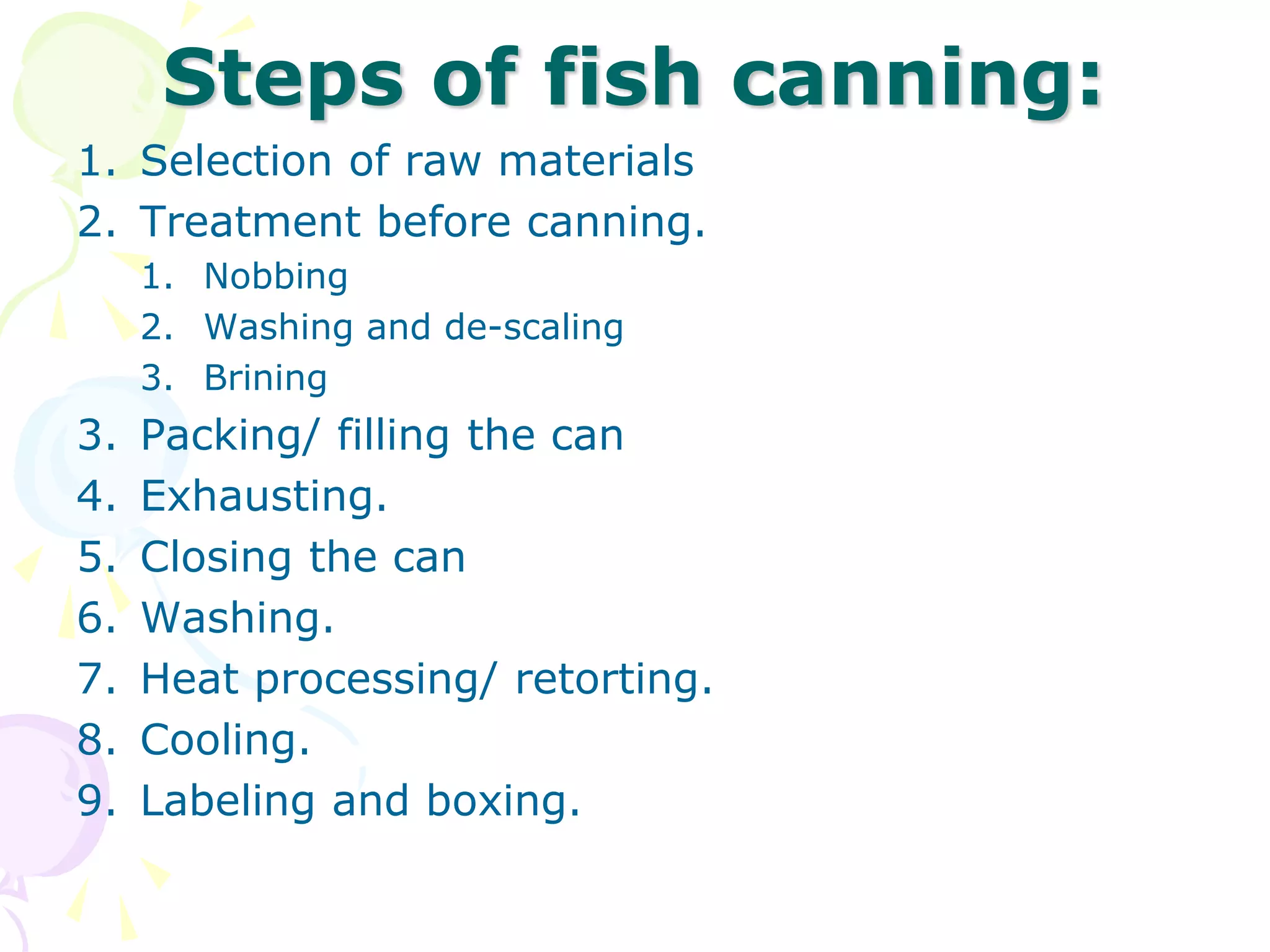

2. The fish canning process involves selecting suitable fish, treating and packing them into cans, exhausting the cans, sealing, washing, heat processing, cooling, and labeling for distribution.

3. Key steps include brining fish to add flavor, packing cans tightly, creating a vacuum through exhausting, fully sealing cans, applying precise heat treatment to achieve commercial sterility, and labeling for identification.