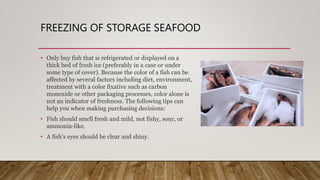

This document discusses the processing and freezing of marine products. It provides guidelines for freezing seafood, including looking for certification labels on shellfish, discarding cracked shells, and checking for leg movement in live crabs and lobsters. The freezing process is described, where the fish's temperature drops through stages of thermal arrest and ice formation. Frozen storage can preserve fish for over a year if done properly by preventing bacterial growth and slowing chemical changes through very low temperatures. Packaging and limiting oxygen exposure can reduce oxidation and dehydration, which are the primary causes of quality deterioration during frozen storage.