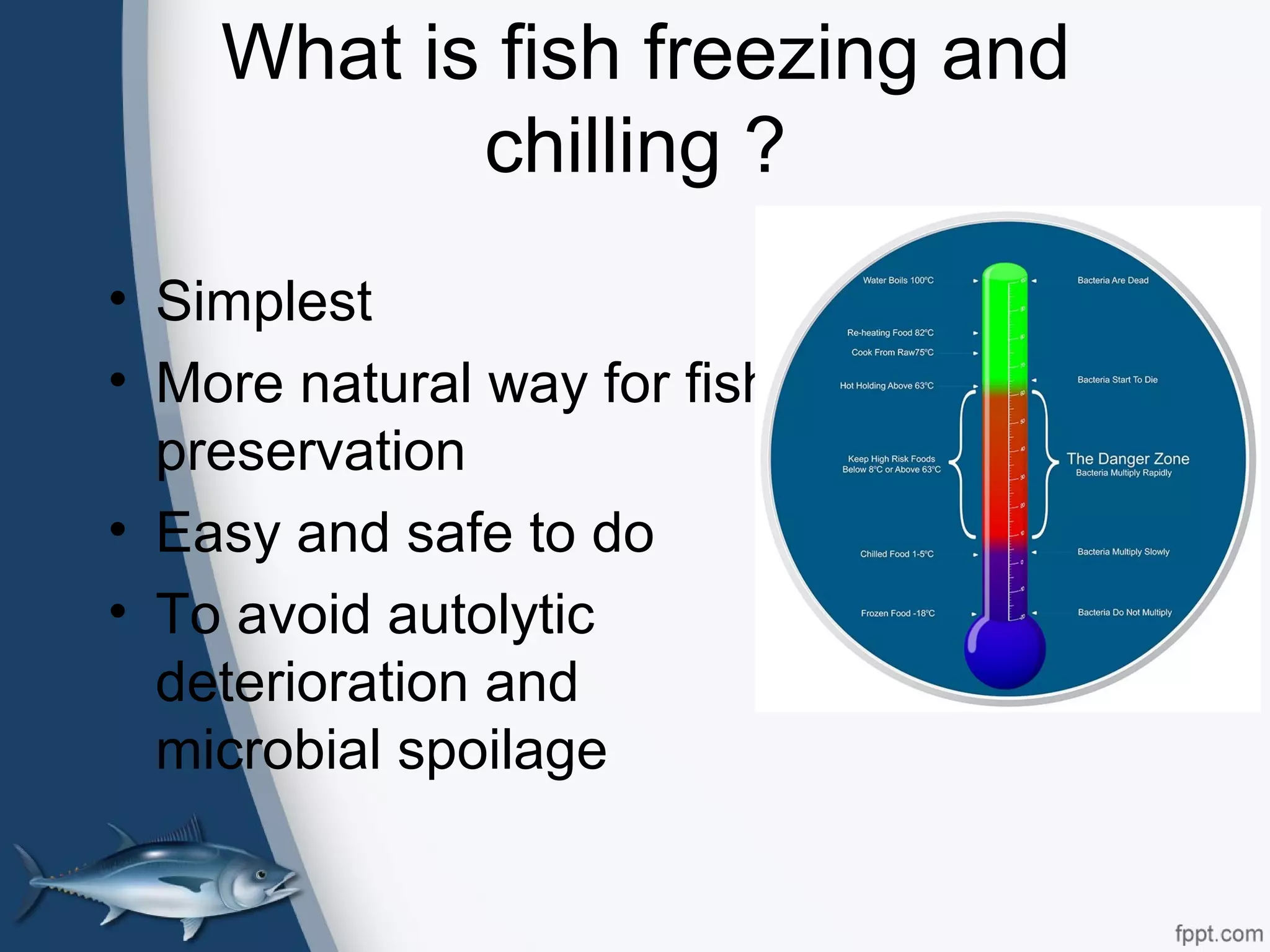

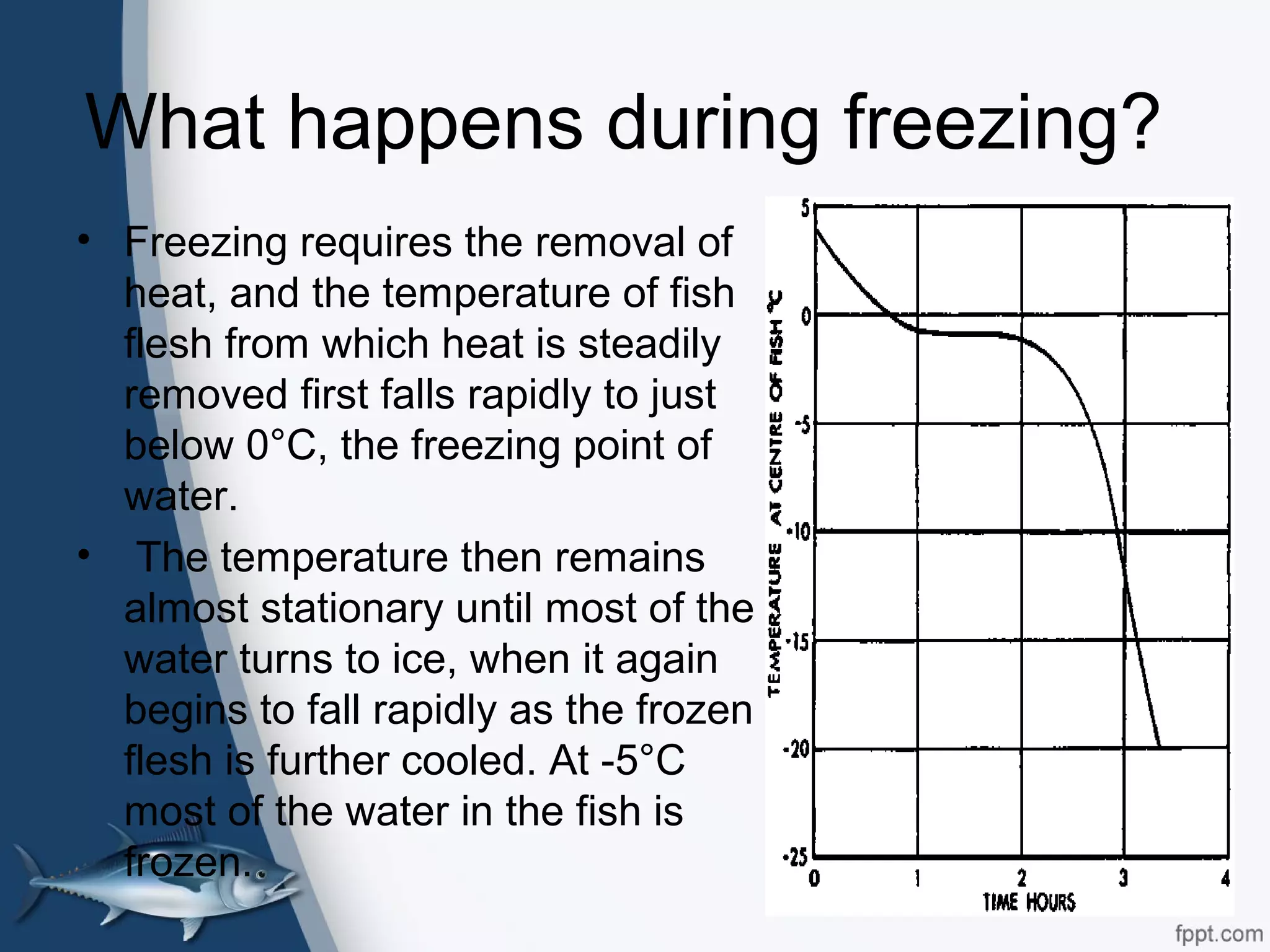

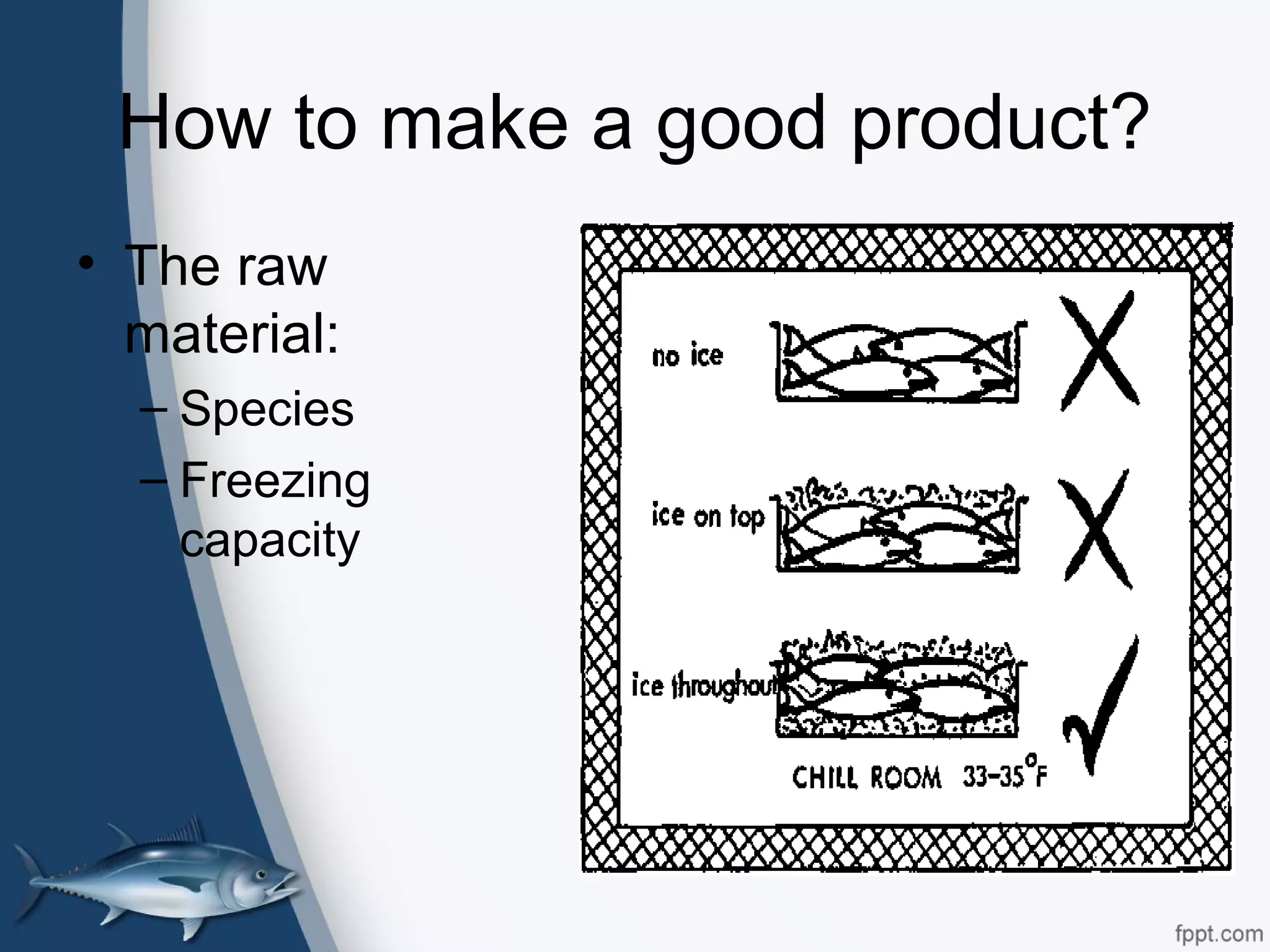

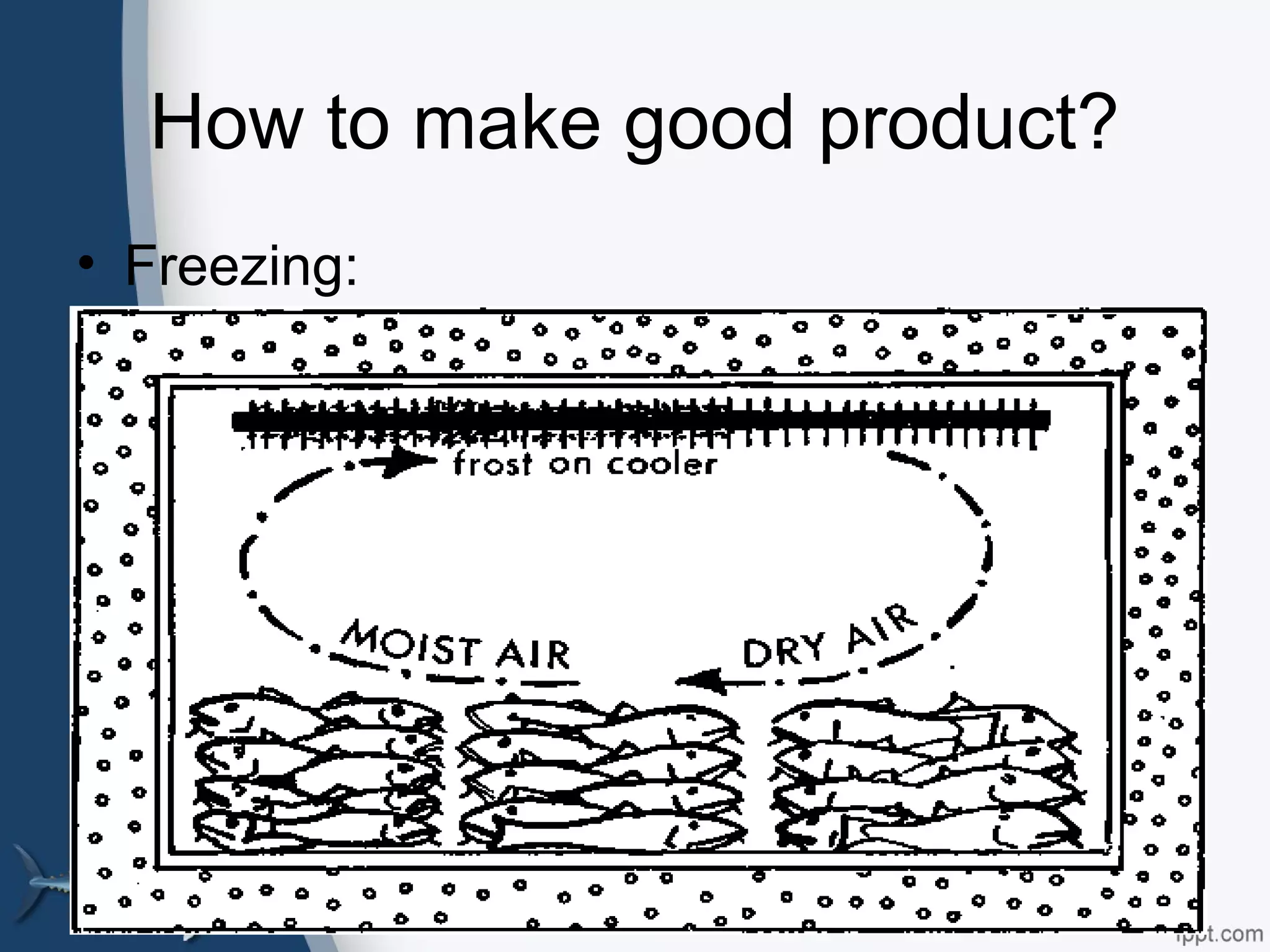

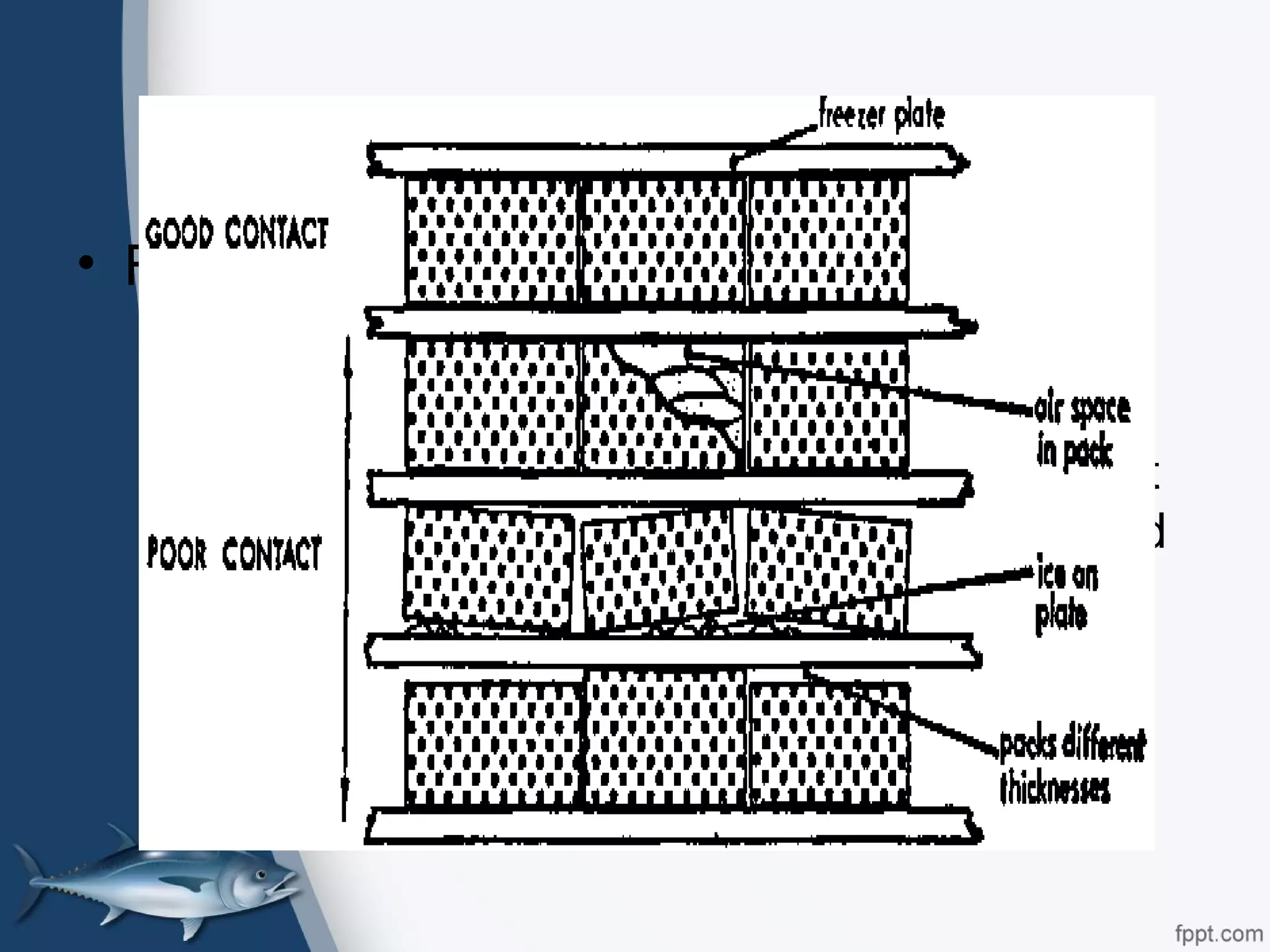

Freezing and chilling fish involves reducing the temperature to preserve it. Chilling means reducing temperature without freezing, while freezing occurs below 0°C. Freezing and chilling fish simply and safely avoids spoilage. The steps are selecting fresh fish, washing or removing scales, wrapping tightly, labeling, and freezing immediately. Freezing slows spoilage so fish maintains quality when thawed. During freezing, heat is removed until water turns to ice. Proper freezing methods and cold storage at -30°C maximize quality and safe storage time.