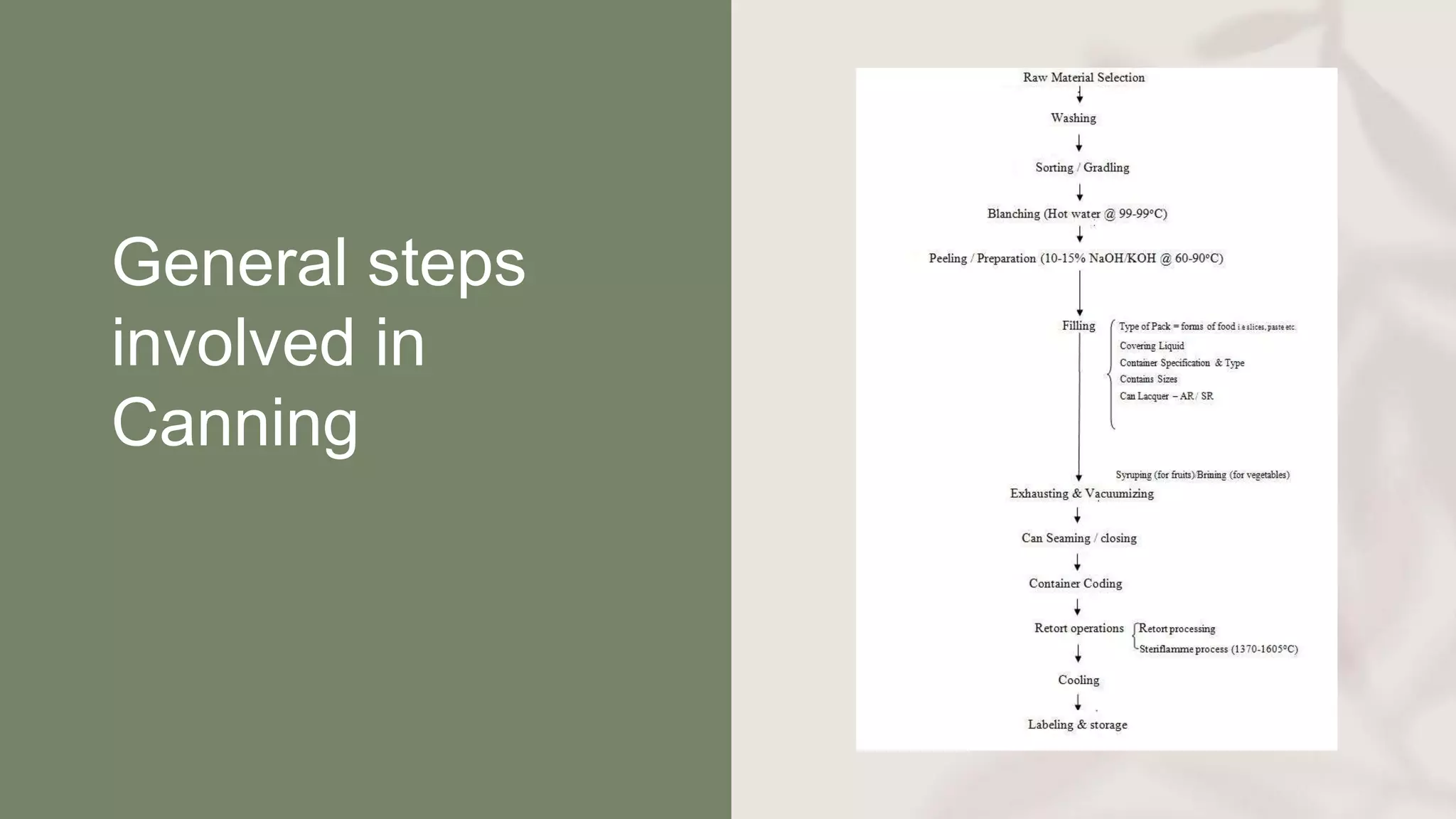

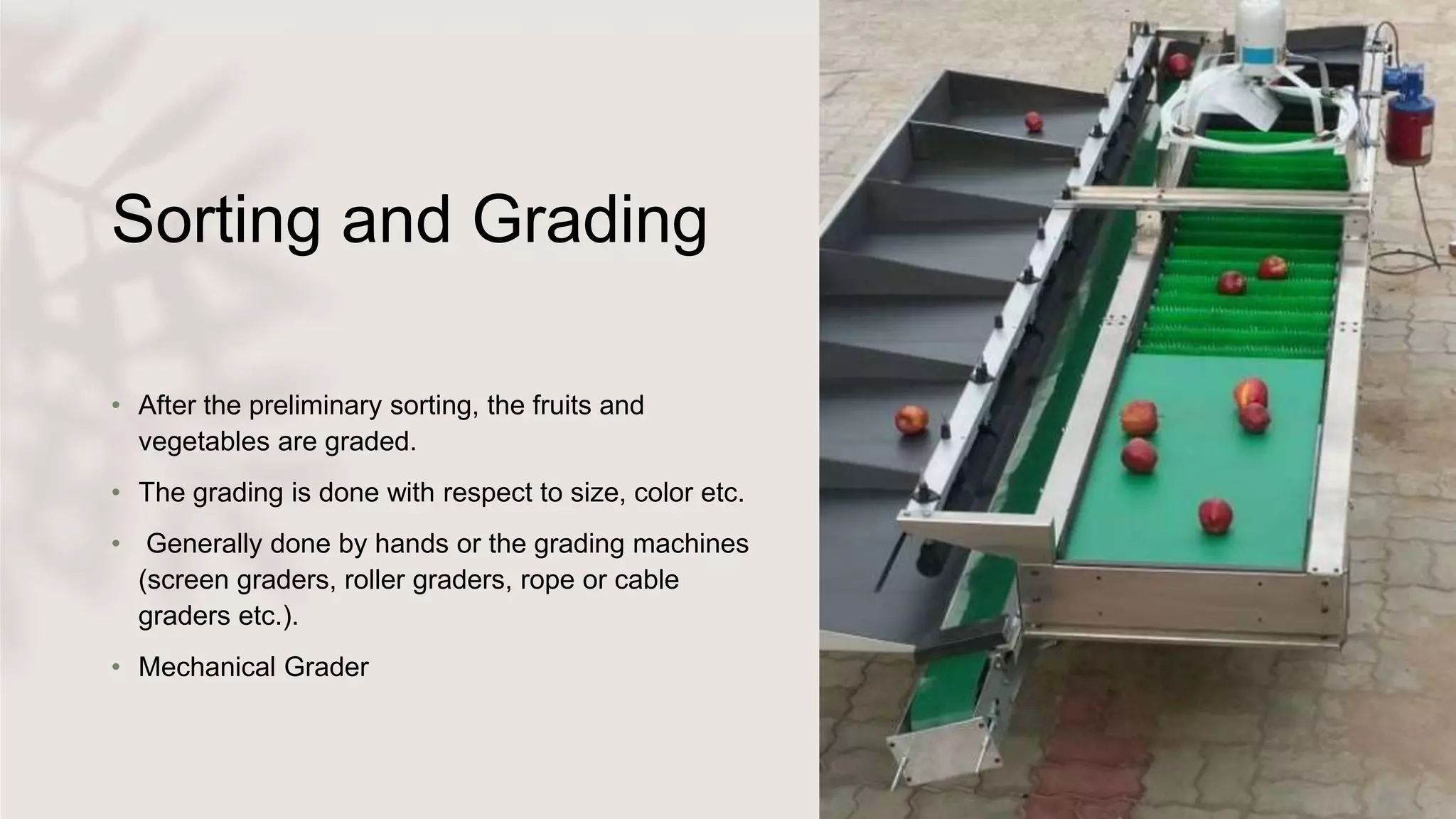

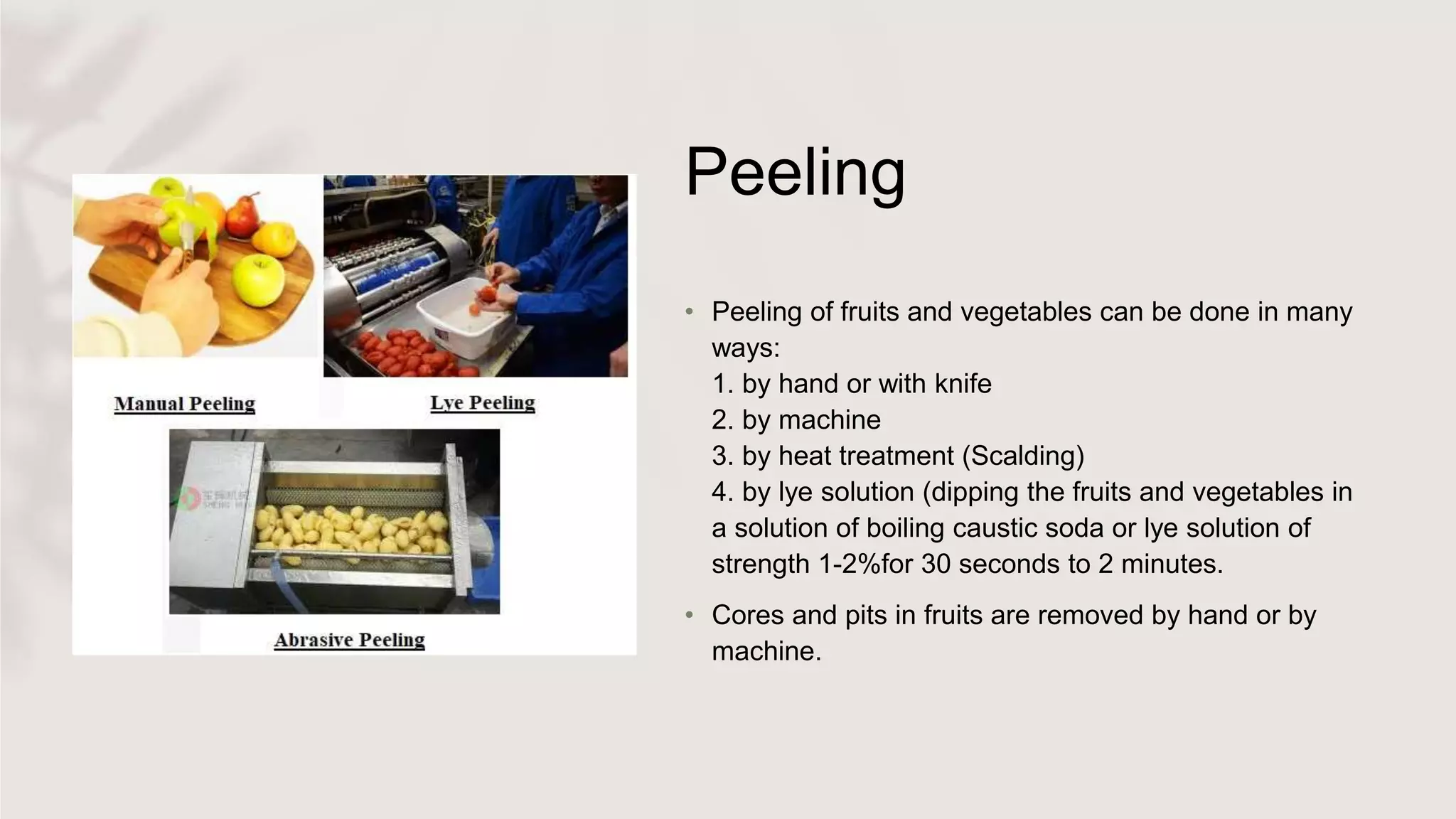

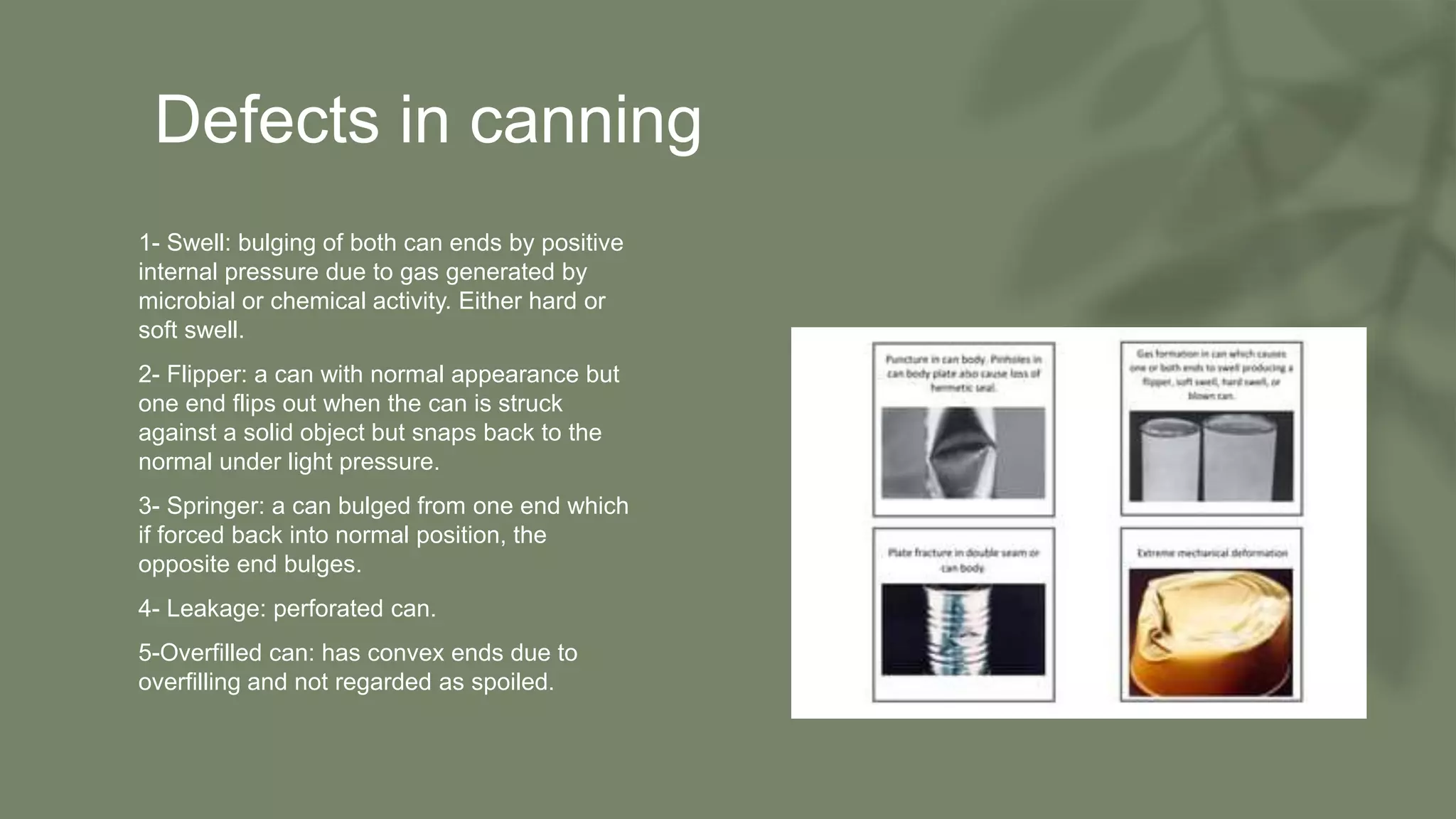

Canning involves processing and sealing food in air-tight containers to preserve it. Heat treatment is used to kill microorganisms and prevent reinfection. Proper canning can provide a shelf life of 1-5 years, or up to 30 years for dried products. The process involves selecting, sorting, washing, peeling, blanching, filling containers, adding syrup/brine, sealing, sterilizing, cooling, labeling and storing the canned food. Metal containers are preferred for canning due to properties like heat conductivity and ability to withstand thermal processing. Defects in canning include swelling, bulging or leakage of containers.