1. The document discusses various fish products including smoked fish, frozen fish, dried fish, and canned fish.

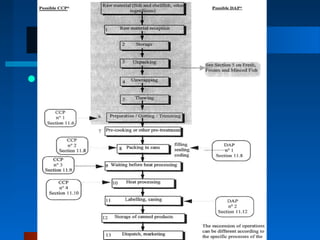

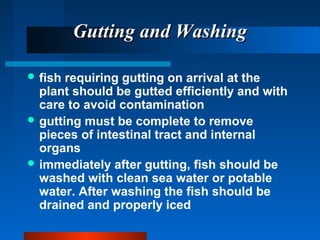

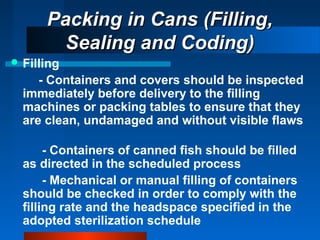

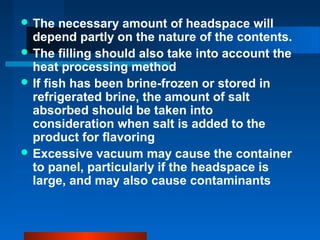

2. For canned fish specifically, it outlines the requirements for raw materials, handling and processing steps such as gutting, washing, pre-cooking, filling cans, sealing, heat processing and cooling, and labeling finished products.

3. Proper handling and processing is important at each step to prevent contamination and ensure the safety of canned fish products.