This document discusses fireball formation and combustion optimization in boilers. It covers topics such as:

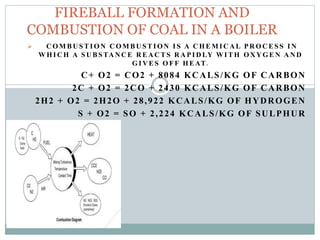

- Types of combustion (complete vs incomplete) and factors affecting combustion

- Temperature, turbulence, and time requirements for combustion

- Technologies for measuring fireball temperature distribution like acoustic and laser methods

- Software systems for advanced combustion control using modeling and CFD simulations

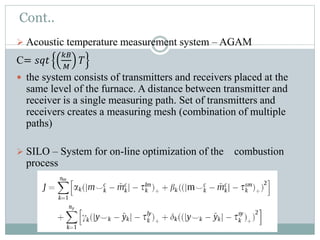

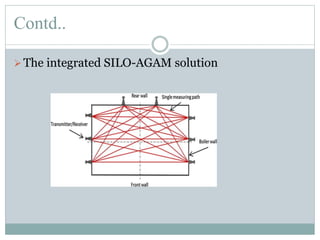

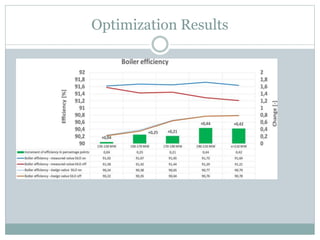

- An integrated solution combining acoustic temperature measurement and an online optimization system

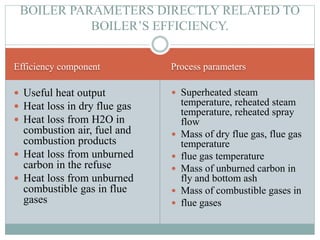

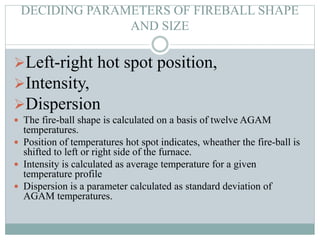

- Process parameters related to boiler efficiency and deciding fireball shape/size

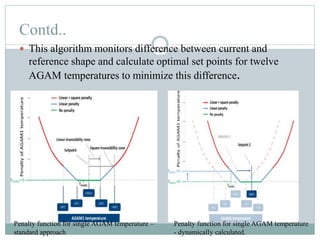

- An algorithm for optimizing burner setpoints to control the fireball shape based on temperature measurements