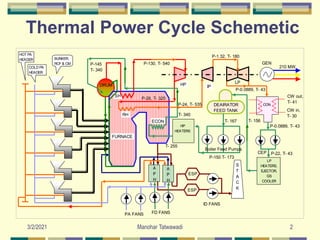

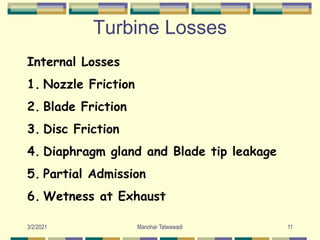

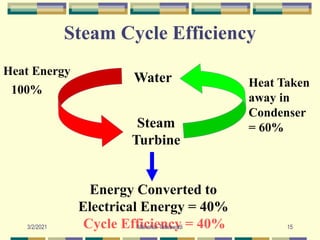

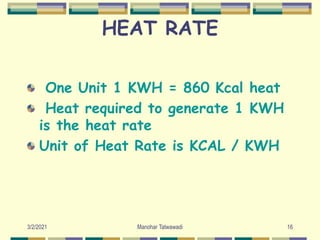

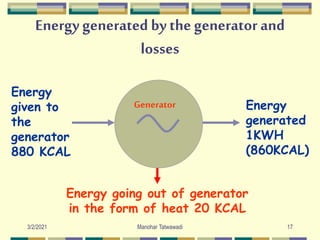

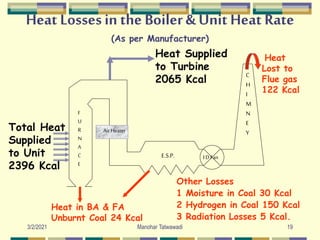

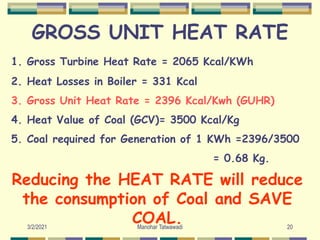

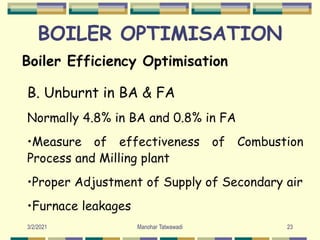

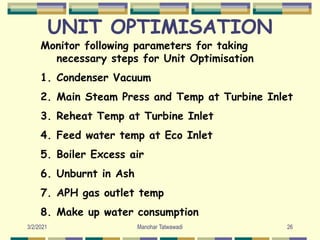

The document discusses the efficiency and heat rate of thermal power stations, detailing the components of thermal power cycles, including boiler and turbine efficiencies. Various losses affecting efficiency, such as moisture in fuel and air, are analyzed, along with methods to optimize performance and reduce heat rates. Additionally, a financial perspective is provided, showing potential cost savings from reducing heat rates in coal usage.