The document describes different types of fire protection systems in a building:

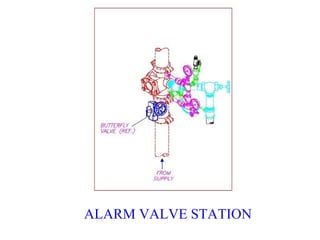

1) A sprinkler system with 4 zones and an alarm valve station.

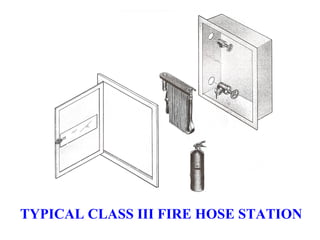

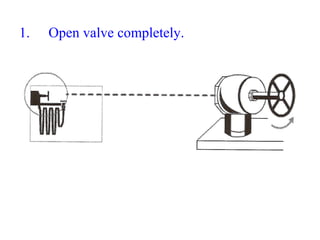

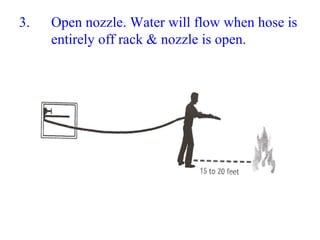

2) A standpipe system with Class III hose stations for occupants and the fire department.

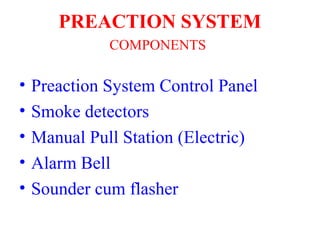

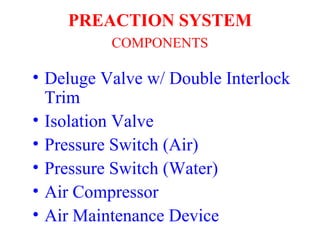

3) A pre-action system for the electrical substation with smoke detectors, a manual pull station, and components like a deluge valve and air compressor.