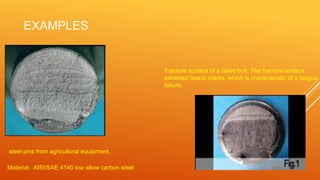

Fatigue is the weakening of a material caused by fluctuating stresses that occurs even at stress levels below the material's tensile strength. It happens in three stages: crack initiation, crack propagation, and final fracture. Fatigue life refers to the total number of cycles a material can withstand before failure. Fatigue strength is the stress level that causes failure after a given number of cycles. Endurance limit is the maximum stress that does not cause failure even after an infinite number of cycles. Fatigue testing determines the fatigue life and failure location of a specimen under repeated stressing to help prevent mechanical failures.