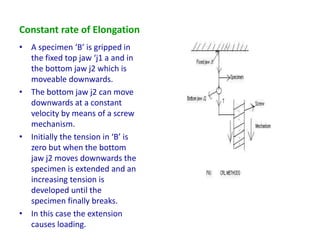

This document discusses two methods for testing the breaking strength of textile specimens: constant rate of loading (CRL) and constant rate of elongation (CRE). Under CRL, a specimen is gripped while a constant force is applied, extending the specimen until it breaks. Under CRE, a specimen is gripped while the bottom jaw moves at a constant velocity, elongating the specimen and developing tension until it breaks. Both methods measure the load and extension at break to determine breaking strength.