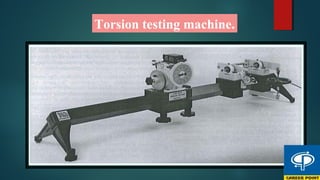

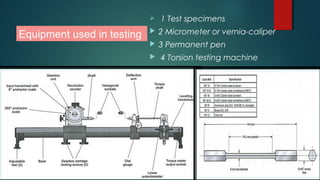

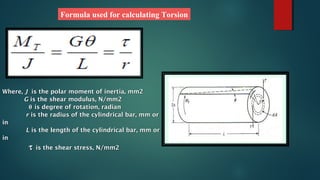

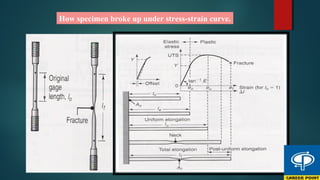

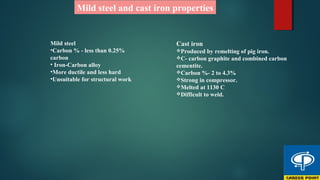

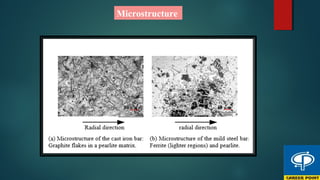

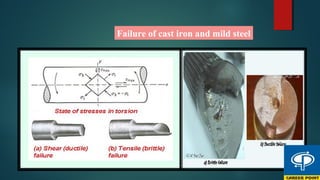

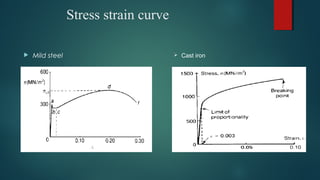

The document summarizes a presentation on torsion testing. It defines torsion as applying a twisting moment or torque to a member. Torsion testing determines parameters like ultimate torsional strength and shear modulus. It describes how torsion occurs in various engineering applications. The presentation covers objectives of torsion testing, the testing machine, formulas used, how materials break under stress, properties of mild steel and cast iron, their microstructures, and failure modes under torsion. It concludes torsion failures differ from tension and provide little deformation, with fracture surfaces related to stress state and two failure types in mild steel and cast iron.