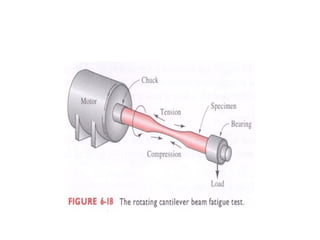

The document outlines the history and mechanisms of fatigue testing as a failure mechanism since the nineteenth century, particularly noting its significance in rail travel and rotating components. It discusses how fatigue failure occurs under cyclic stress, the factors that influence fatigue life, and the necessity for fatigue testing in design to predict service life accurately. Additionally, it highlights the relationship between stress cycles and material performance, emphasizing that higher strength materials do not necessarily improve fatigue life.