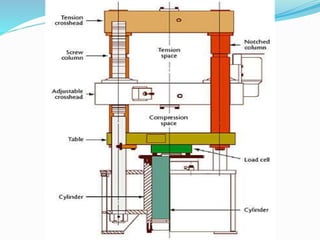

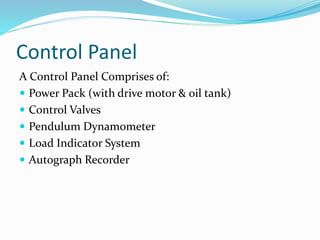

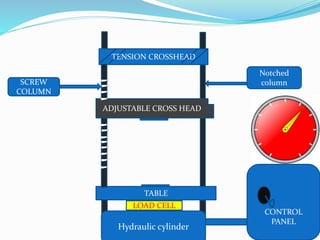

A universal testing machine is used to perform tensile, compressive, and shear strength tests on materials and structures. It consists of a loading unit, control panel, and control devices. The document outlines the components, working principle, and procedures for conducting compressive, tensile, and shear tests using a universal testing machine. Specimens are gripped firmly and loaded incrementally until the yield point is reached, then the maximum load is recorded to determine the material's strength. Proper specimen dimensions and a uniform loading rate without jerks are important to get accurate test results.