The document discusses the experimental behavior of self-compacting concrete (SCC) using ground granulated blast furnace slag (GGBS) as a partial replacement for cement. The study aims to improve compressive strength while reducing CO2 emissions and costs, exploring various mix designs and the effects of additives like poly carboxylic ether. Tests are conducted to measure workability and strength, with results indicating the potential for economical and efficient concrete solutions in construction.

![206

International Journal of Research and Innovation (IJRI)

Conclusion

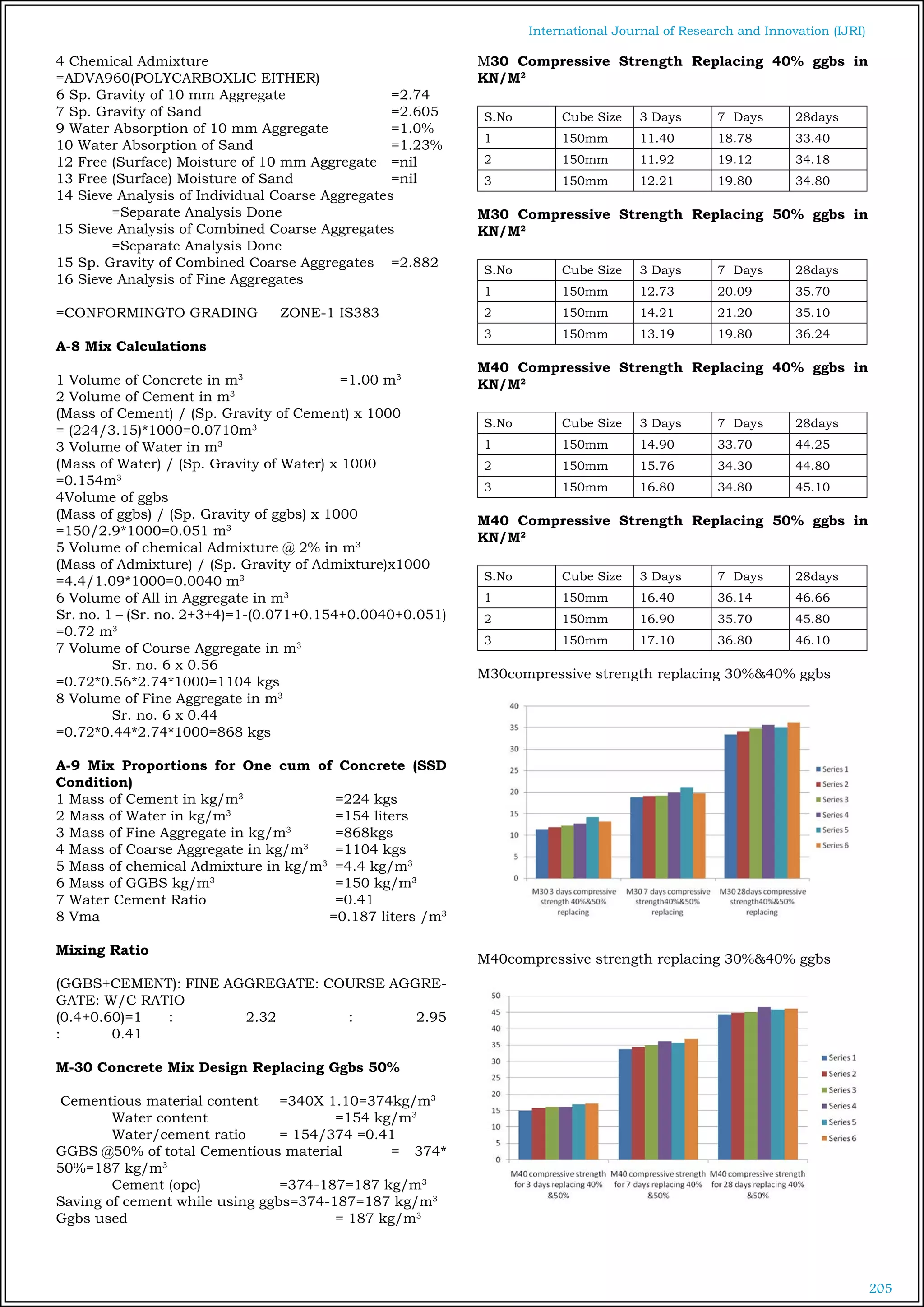

• When compare to the previous papers test’s on replacing GGBS

above 30% the compressive strength have reduced, for every in-

terval of replacing 5%. Added Conplast SP430 as super plasti-

cizer and maintained w/c ratio is kept constant throughout the

investigation as 0.45.

• as per Results suggest that as much of 50% of cement can be

replaced without any significant consequences on the concrete,

by using the chemical admixture as super plasticizer ADVA960

(poly carboxylic either) is a retarder increase the initial setting

time

• Compressive strength is increased by replacing 50% of GGBS

for cement and maintained w/c ratio as per mix design obtained,

the mineral admixture replacement have a better workable con-

crete.

• Avg Compressive Strength For M30scc Replacing 40%GGBS 3

days=11.84 KN/M2

• Avg Compressive Strength For M30scc Replacing 40%GGBS 7

days=19.23 KN/M2

• Avg Compressive Strength For M30scc Replacing 40%GGBS 28

days=34.12 KN/M2

• Avg Compressive Strength For M30scc Replacing 50%GGBS 3

days=13.37 KN/M2

• Avg Compressive Strength For M30scc Replacing 50%GGBS 7

days=20.36 KN/M2

• Avg Compressive Strength For M30scc Replacing 50%GGBS 28

days=35.69 KN/M2

• Avg Compressive Strength For M40scc Replacing 40%GGBS 3

days=15.82 KN/M2

• Avg Compressive Strength For M40scc Replacing 40%GGBS 7

days=34.26 KN/M2

• Avg Compressive Strength For M40scc Replacing 40%GGBS 28

days=44.71 KN/M2

• Avg Compressive Strength For M40scc Replacing 50%GGBS 3

days=16.80 KN/M2

• Avg Compressive Strength For M40scc Replacing 50%GGBS 7

days=36.21 KN/M2

• Avg Compressive Strength For M40scc Replacing 50%GGBS 28

days=46.18 KN/M2

Scope for Further Study

SCC can be replaced upto 50% further test can be carried out by

increasing percentage and maintain w/c ratio as per mix design,

Since there is no standard method of mix design is available for

SCC. Hence the mix proportion is obtained as per the guidelines

of IS10262-2009 so further study’s can be carried out to find the

Durability &serviceability factors, temperature effect and flexural

strength add present of GGBS more than 50% may shows vari-

ation in obtaining strength.

References

• [1] k.l.n madhav rao “experimental behavior of self compaction

concrete with GGBS “ by using mix design IS 10262-2009and IS

456-2000.

• B. H. Venkataram Pai, Maitreyee Nandy, A. Krishnamoorthy,

Pradip Kumar Sarkar, C.Pramukh Ganapathy, Philip George,

“Development of self compacting concrete with various mineral

admixtures”, American Journal of Civil Engineering, May 30,

2014.

• Dinakarpasla,Mr. Kaliprasannasethy and Umesh c sahoo, “

Development of High Strength Self-Compacting Concrete with

Ground Granulated Blast Furnace Slag – A New Mix Design

Methodology”

• K. Ganesh Babu and V. Sree Rama Kumar, “Efficiency of

GGBS in concrete” , Cement and Concrete Research 30 (2000),

PP.1031- 1036.

• Mallikarjuna Reddy V, Seshagiri Rao M V, Srilakshmi P and

SateeshKumar B,“Effect of W/C Ratio on Workability and Me-

chanical Properties of High Strength Self Compacting Con-

crete (M70 Grade)” International Journal of Engineering Re-

search and Development.

• Mr. Dhruvkumar H. Patel, Mr Dixitkumar D. Patel, Mr

Dhaval P. Patel, Mr Vivek A. Patva, Mr Yashasvikumar R.

Patel, “ Literature Review On Self Compacting Concrete”, In-

ternational Journal For Technological Research In Engineering,

Vol 1, No 9, May-2014.

• P. Ramanathan, I. Baskar, P. Muthupriya, and R. Venkatasu-

bramani .

“ Performance of Self-compacting concrete containing differ-

ent mineral admixtures”. KSCE Journal of Civil Engineering

17(2):465-472, May 30. 2012.

• SabeerAlavi.C, I.Baskar and R.Venkatasubramani , “Strength

and Durability Characteristics of GGBFS based SCC , Interna-

tional Journal of Emerging trends in Engineering and Develop-

ment March (2013).

• EFNARC,“Specification and guidelines for Self Compacting con-

crete”, UK (2002).

• Jump up^ Winnefeld, F; Becker, S; Pakusch, J; Goetz, T (2011)

"Effects of the molecular architecture of comb-shaped super

plasticizers on their performance in cementitious systems". Ce-

ment and ConcreteComposites 41 (10): 1058. doi:10.1016/j.

cemconcomp.2006.12.006.

• Jump up^ Plank, J; Pollmann, K; Zouaoui, N; Andres, P;

Schaefer, C (2007). "Synthesis and performance of methacrylic

ester based polycarboxylate superplasticizers possessing hy-

droxy terminated poly(ethylene glycol) side chains". Cement

and Concrete Research 29 (4): 251. doi: 10.1016/j.cemconres

.2008.01.007.

Author

K.L.N.Madhav rao,

Research Scholar,

Department of Civil Engineering,

Aurora's Scientific Technological and Research Academy,

Bandlaguda,Hyderabad,

India.

Mythili Rao,

Assistant Professor,

Department of Civil Engineering,

Aurora's Scientific Technological and Research Academy,

Bandlaguda,Hyderabad, India.](https://image.slidesharecdn.com/ijri-cce-02-0012-160413093634/75/EXPERIMENTAL-BEHAVIOUR-OF-SELF-COMPACTING-CONCRETE-USING-GGBS-WITH-PARTIAL-REPLACMENT-OF-CEMENT-7-2048.jpg)