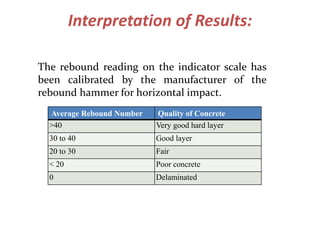

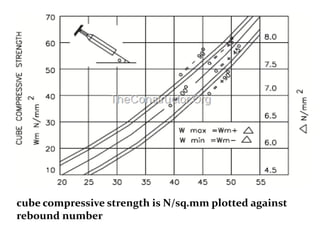

The document discusses the rebound hammer test, a non-destructive method for assessing the compressive strength of concrete through the measurement of rebound values related to surface hardness. The procedure, advantages, and disadvantages of the test are outlined, concluding that while the test is efficient and easy to perform, it has limitations such as evaluating local points only and being unreliable for flaw detection. Overall, combining rebound testing with traditional methods yields the best results for determining concrete strength without damaging the structure.