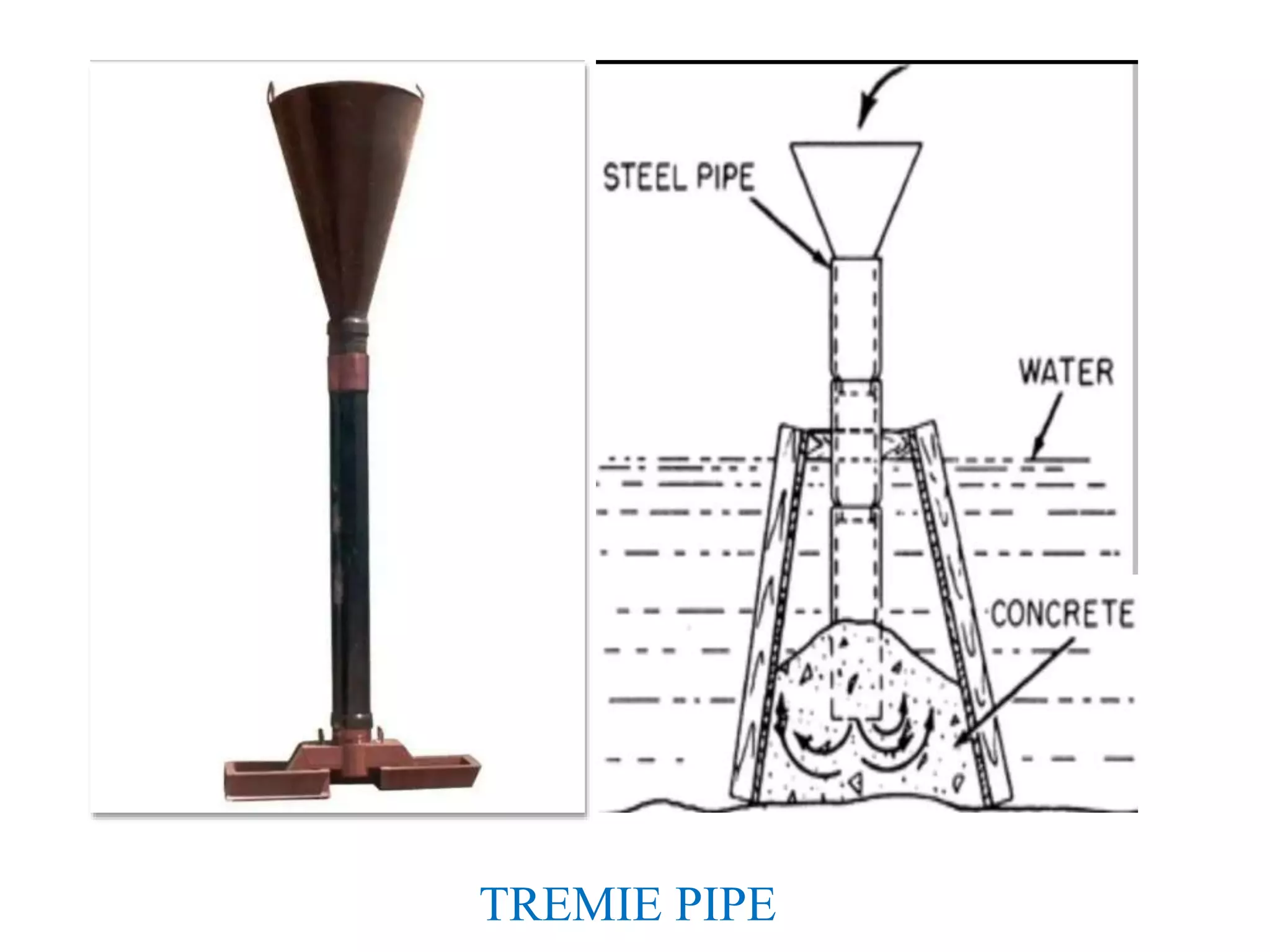

This document discusses placing and compaction of concrete. Placing involves depositing fresh concrete in its final position without dropping from height or piling to avoid segregation. Foundations require trenches be excavated and beds prepared before concrete is placed using chutes or tremie pipes for deep placements. Compaction removes air bubbles and improves packing using hand tools, internal vibrators like poker vibrators inserted in concrete, or external vibrators applying surface vibration. Proper placing and compaction results in dense, strong concrete.