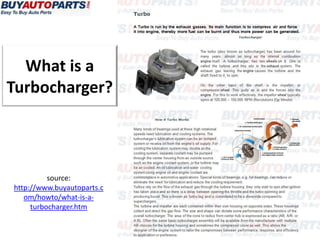

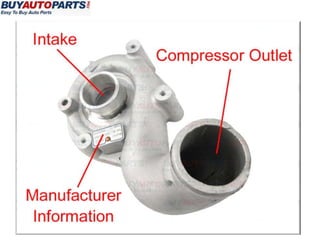

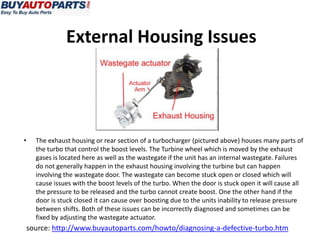

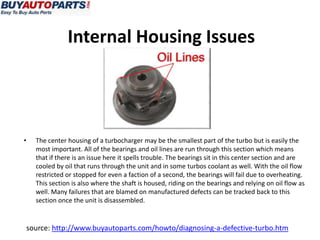

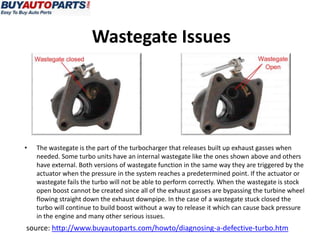

The document provides an overview of turbochargers, explaining their function, components, and common issues such as turbo lag, wastegate operation, and diagnostic methods for failure. It discusses how turbochargers compress air to enhance engine power, the significance of lubrication and cooling systems, and the effects of exhaust flow control by wastegates. Additionally, it details potential causes of failure, such as oil starvation and foreign object damage, emphasizing the importance of maintenance for longevity.