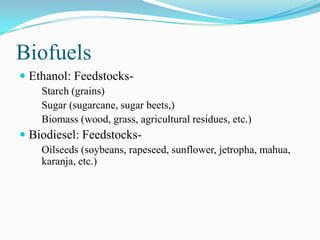

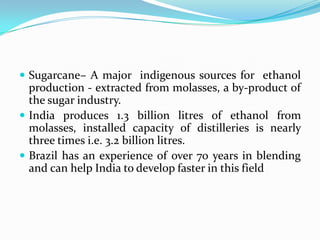

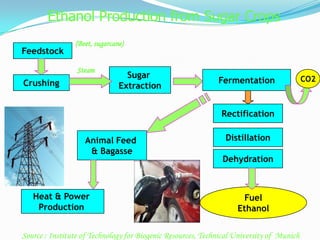

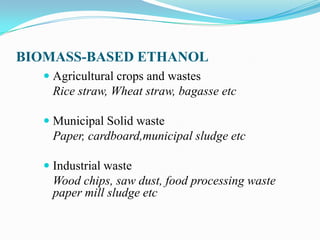

This document discusses biofuels such as ethanol and biodiesel. It provides information on their production sources and feedstocks. Ethanol can be produced from starch, sugar, and cellulosic biomass, with major global sources including sugarcane, corn, and cassava. Biodiesel is produced from oilseed crops like soybeans and rapeseed. The document also outlines the history and current state of biofuel production and use globally, particularly in countries like Brazil, the US, Europe, and India. It notes the potential benefits of biofuels in reducing dependence on crude oil and lowering emissions.