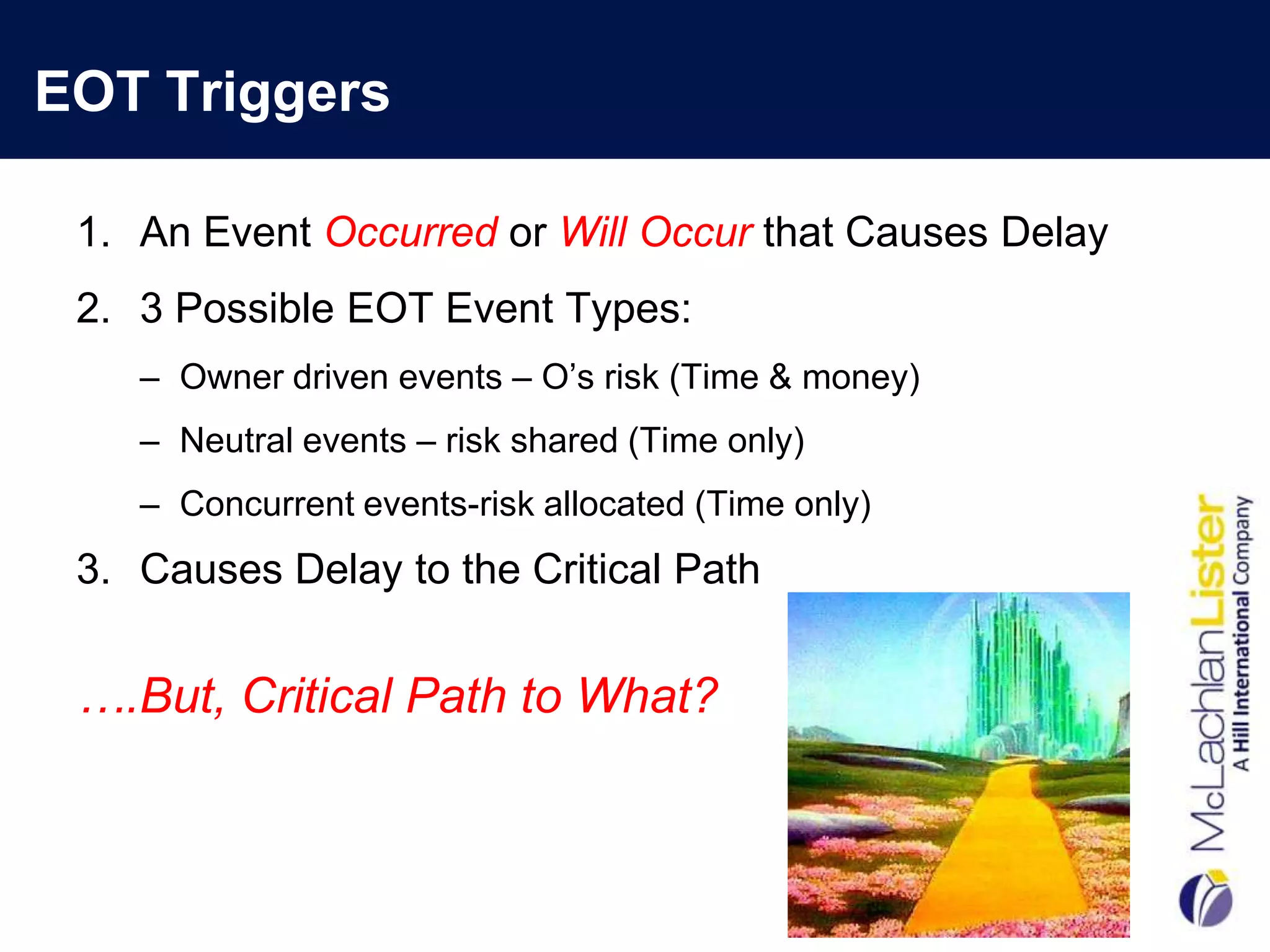

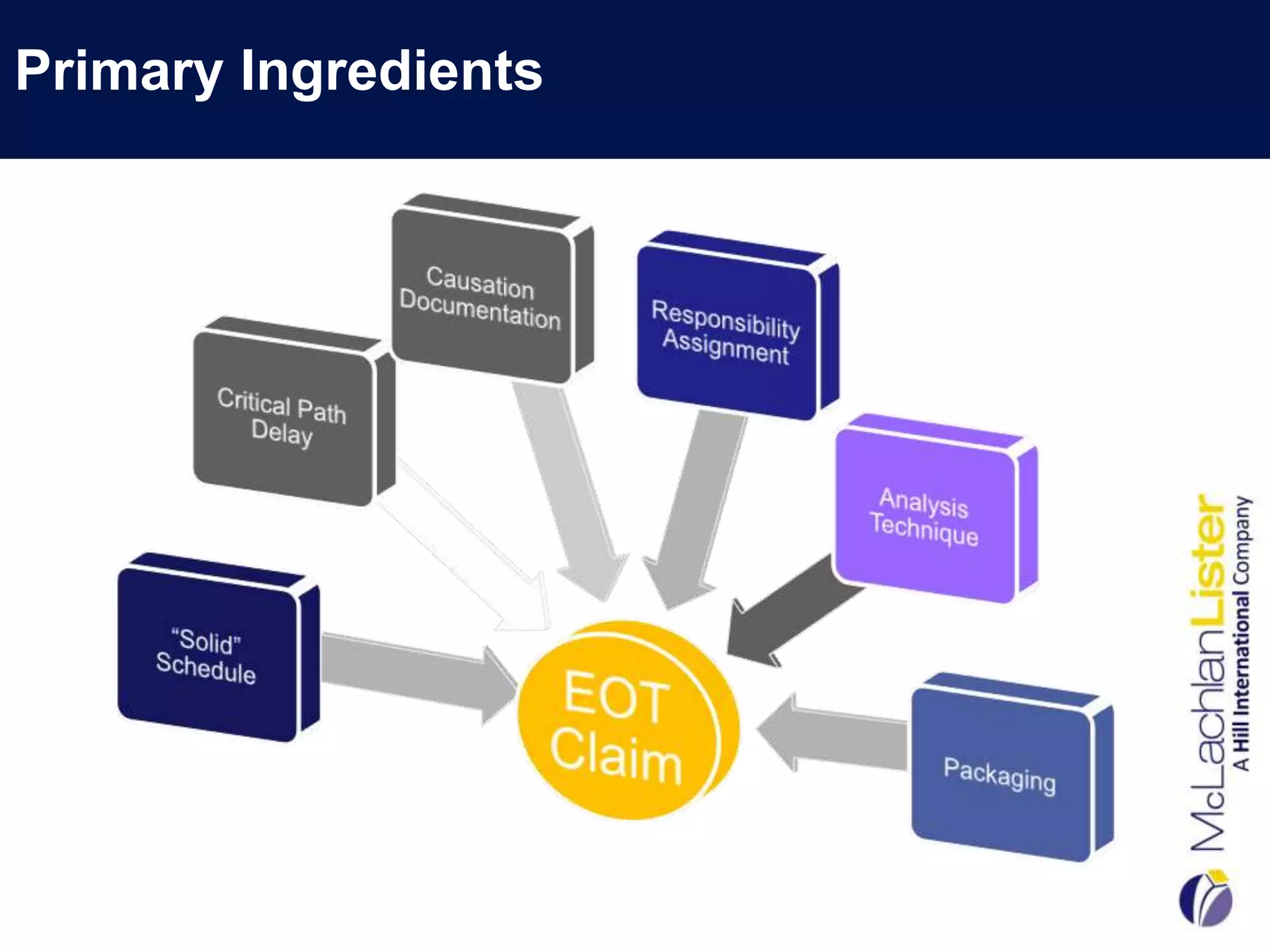

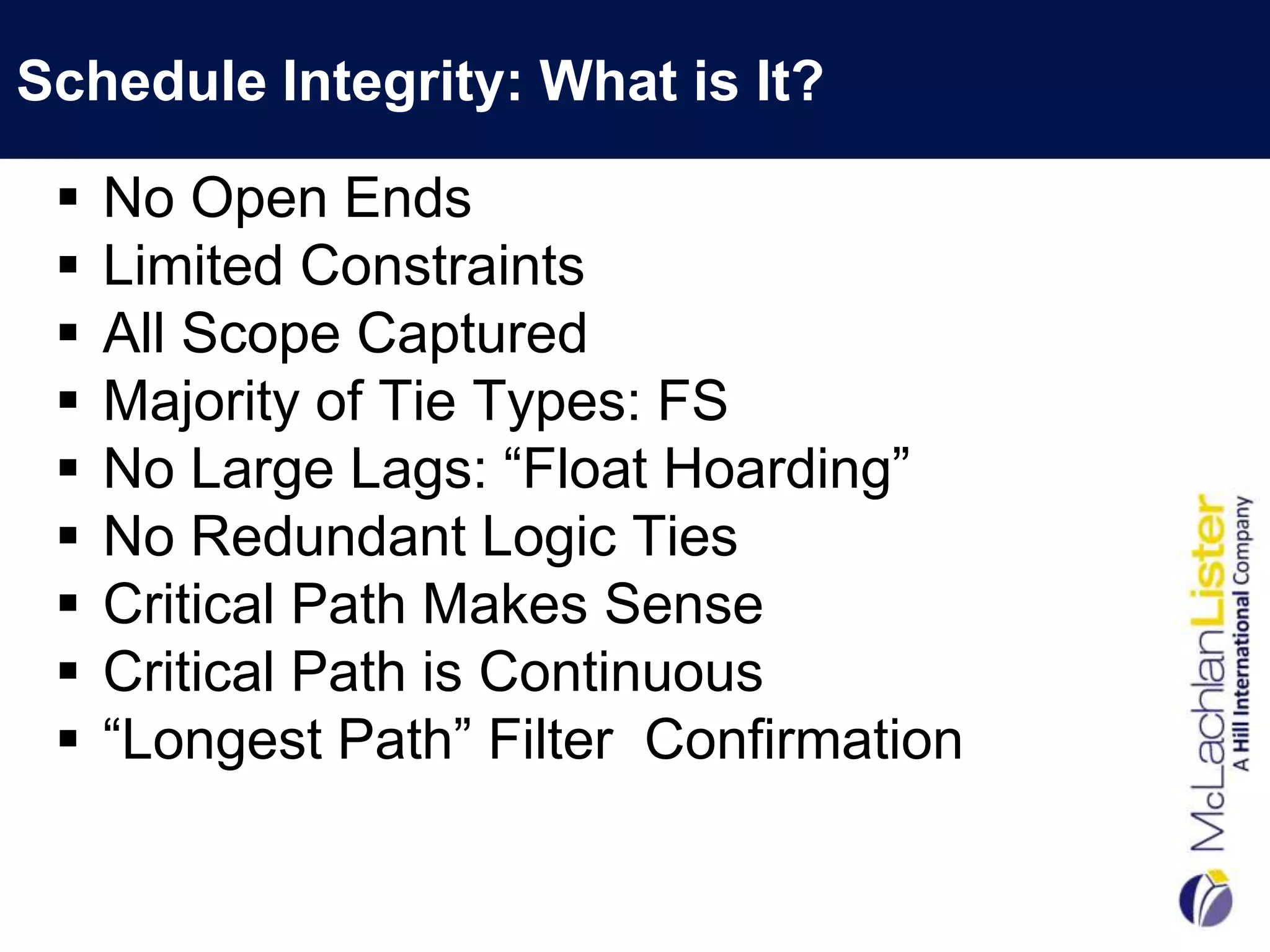

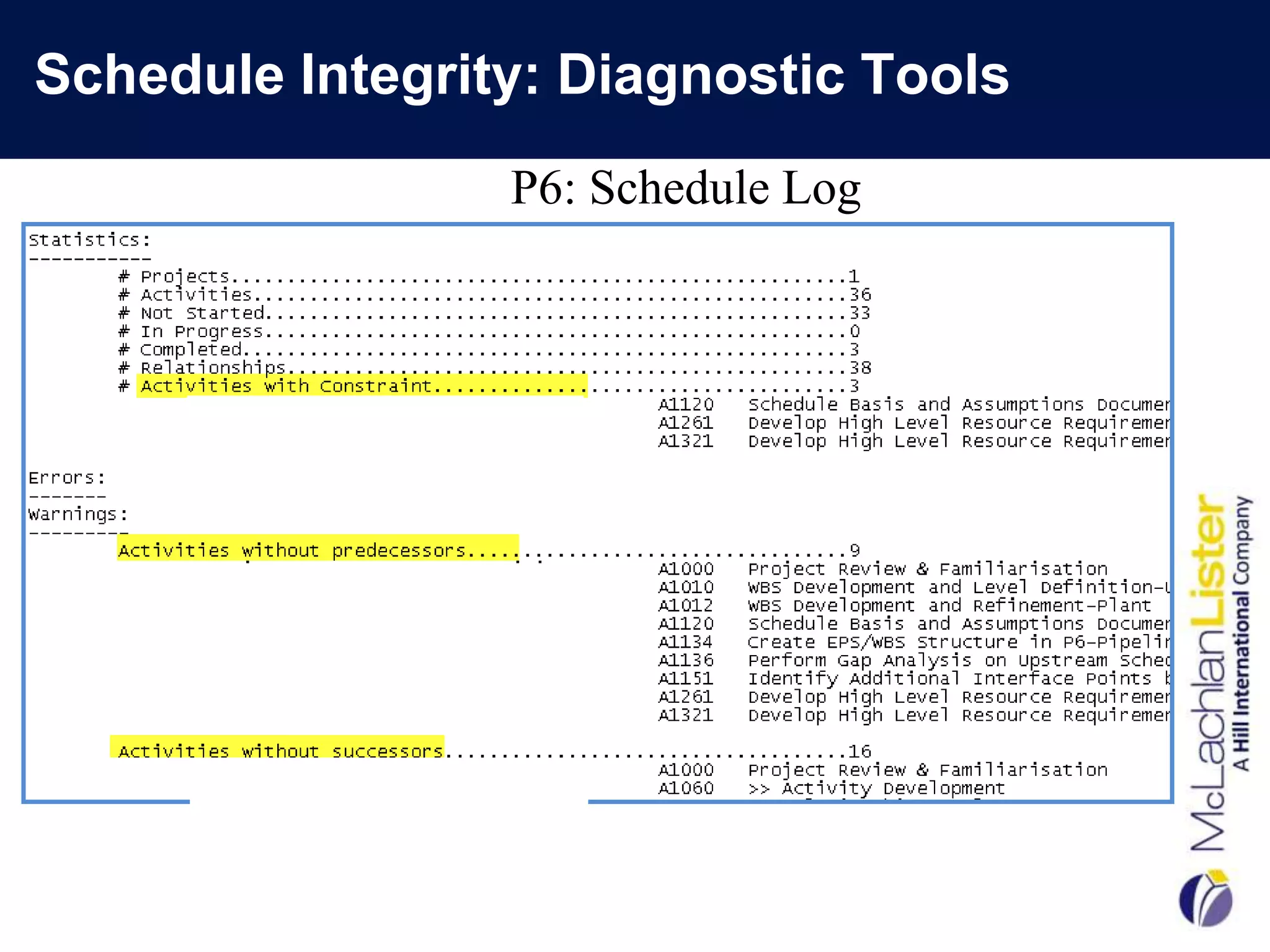

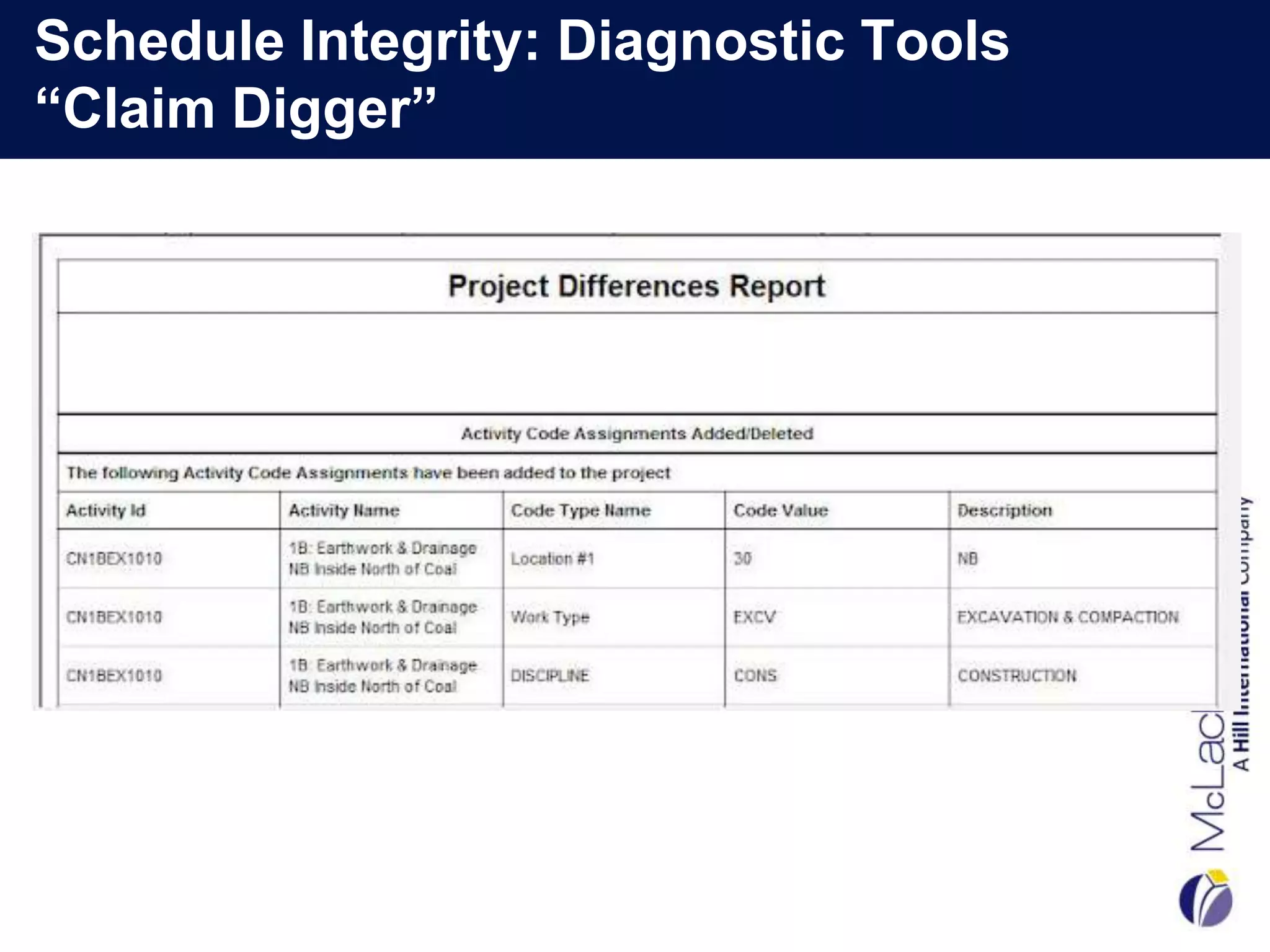

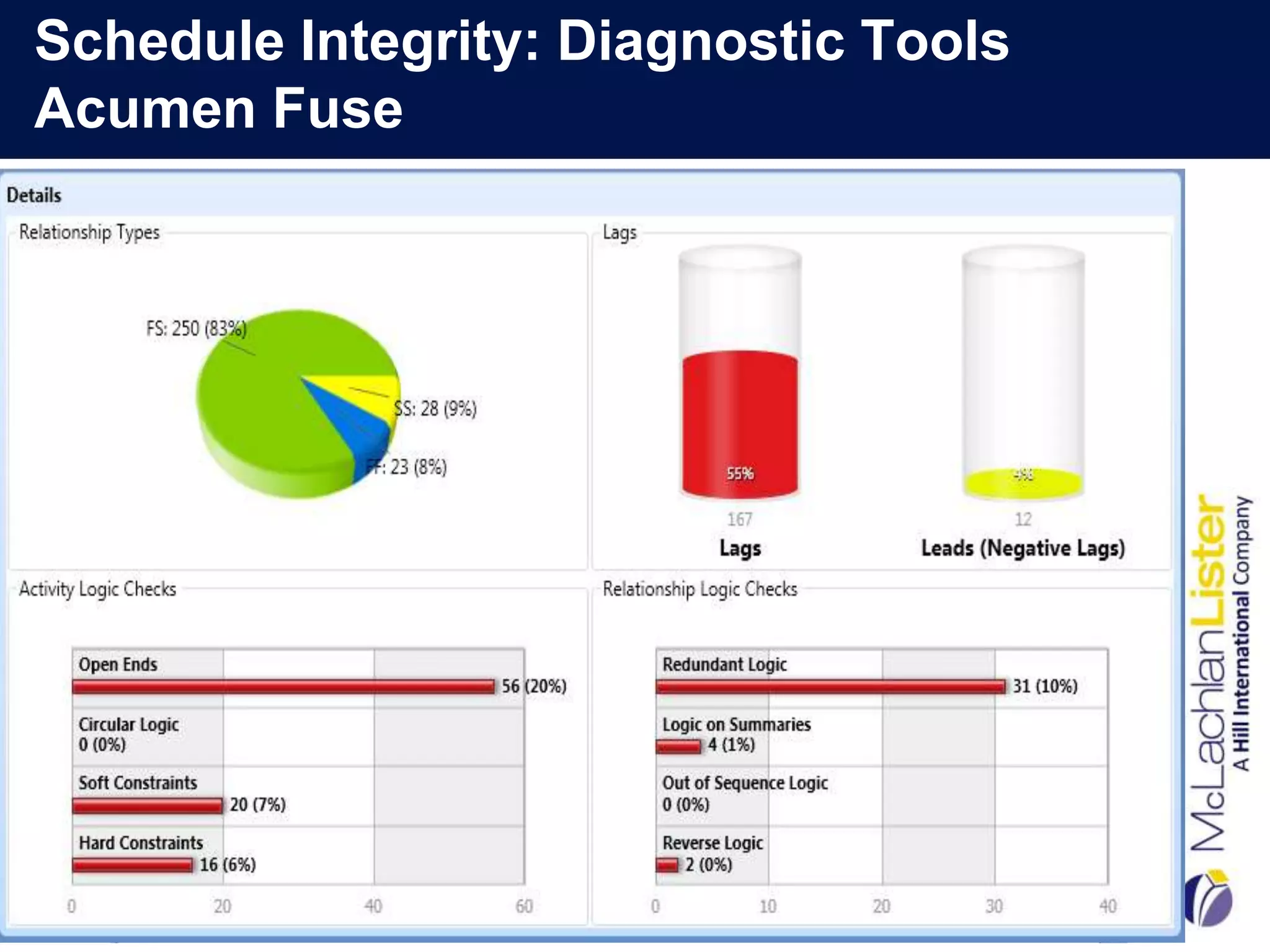

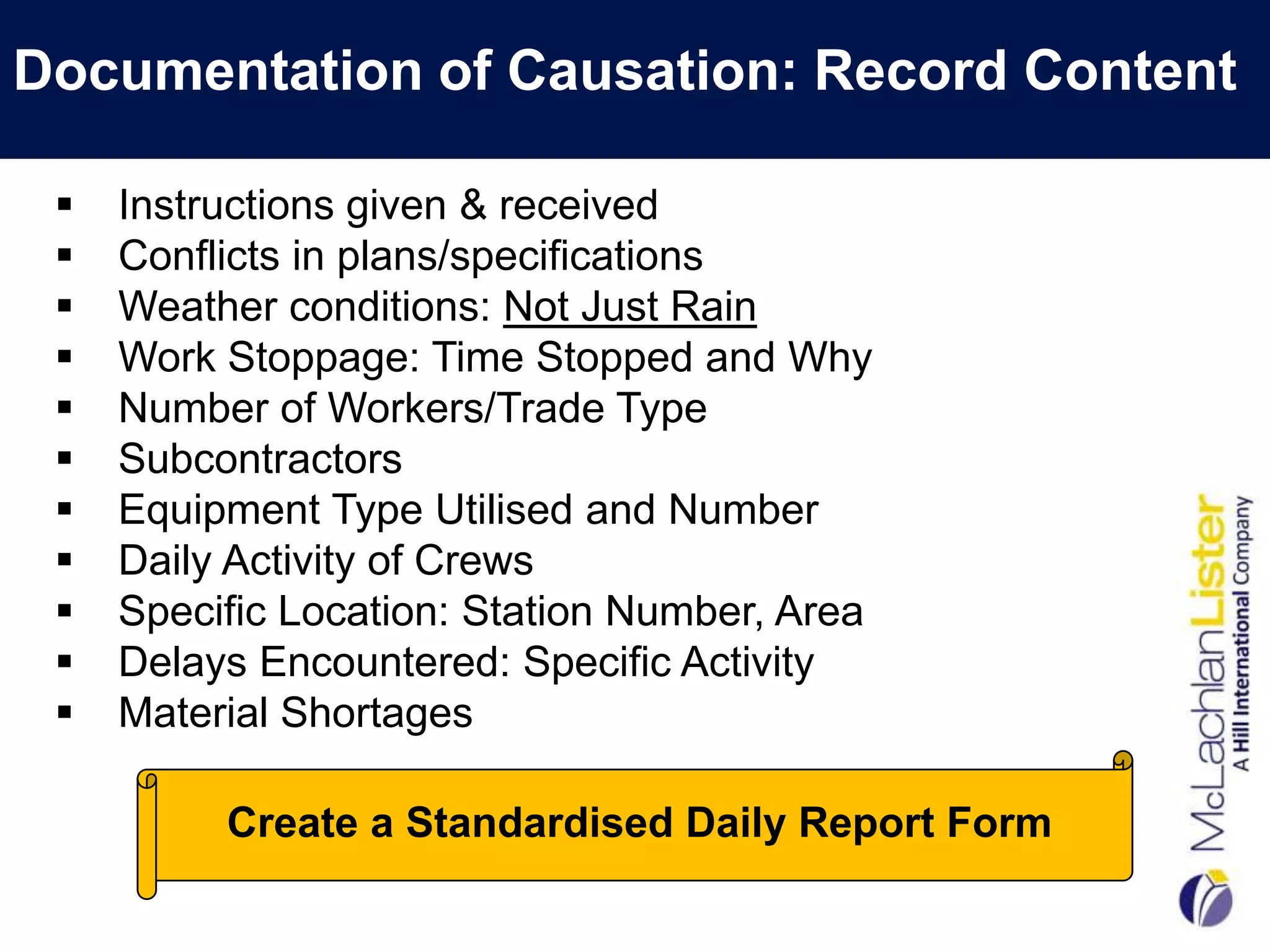

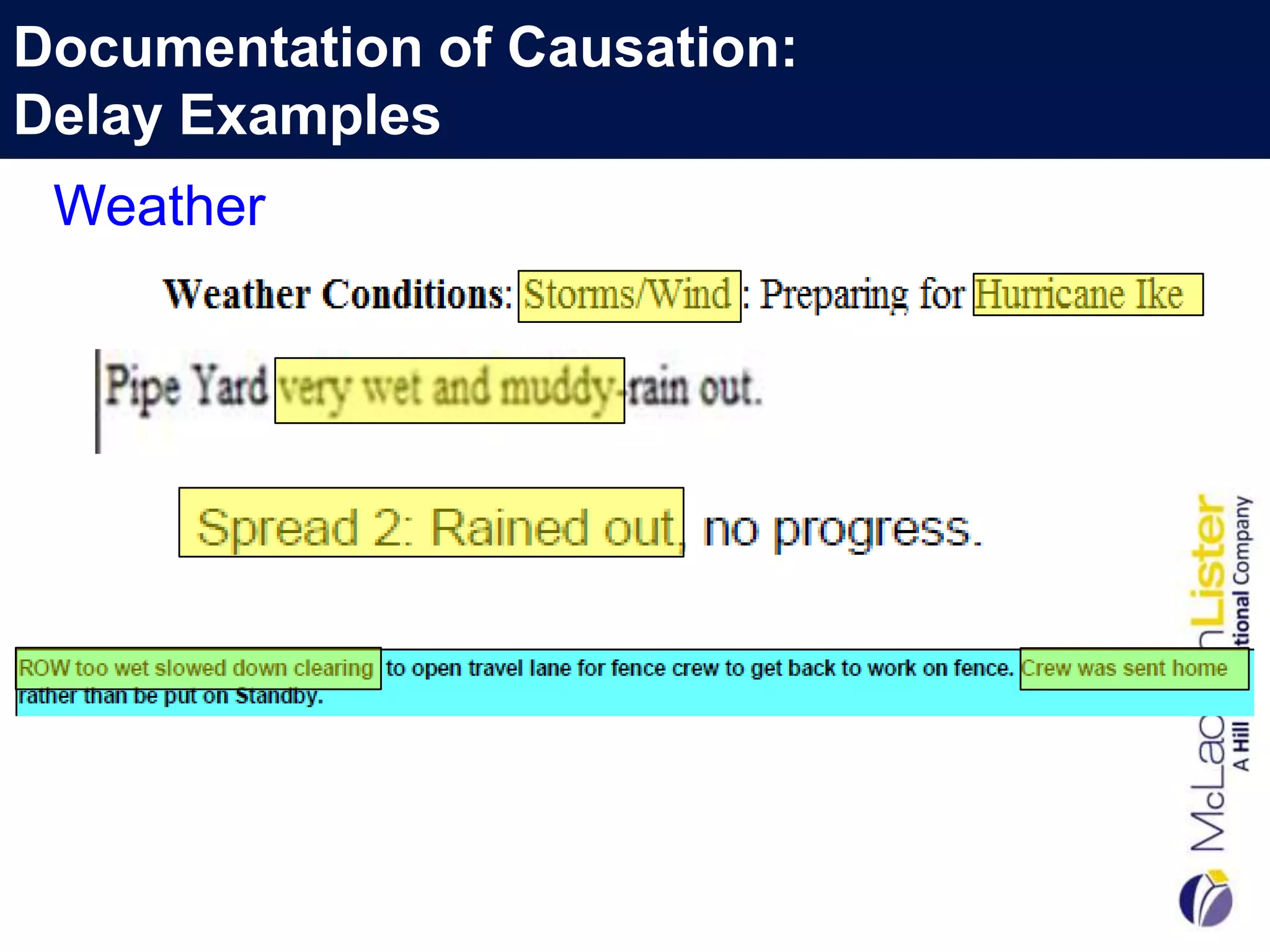

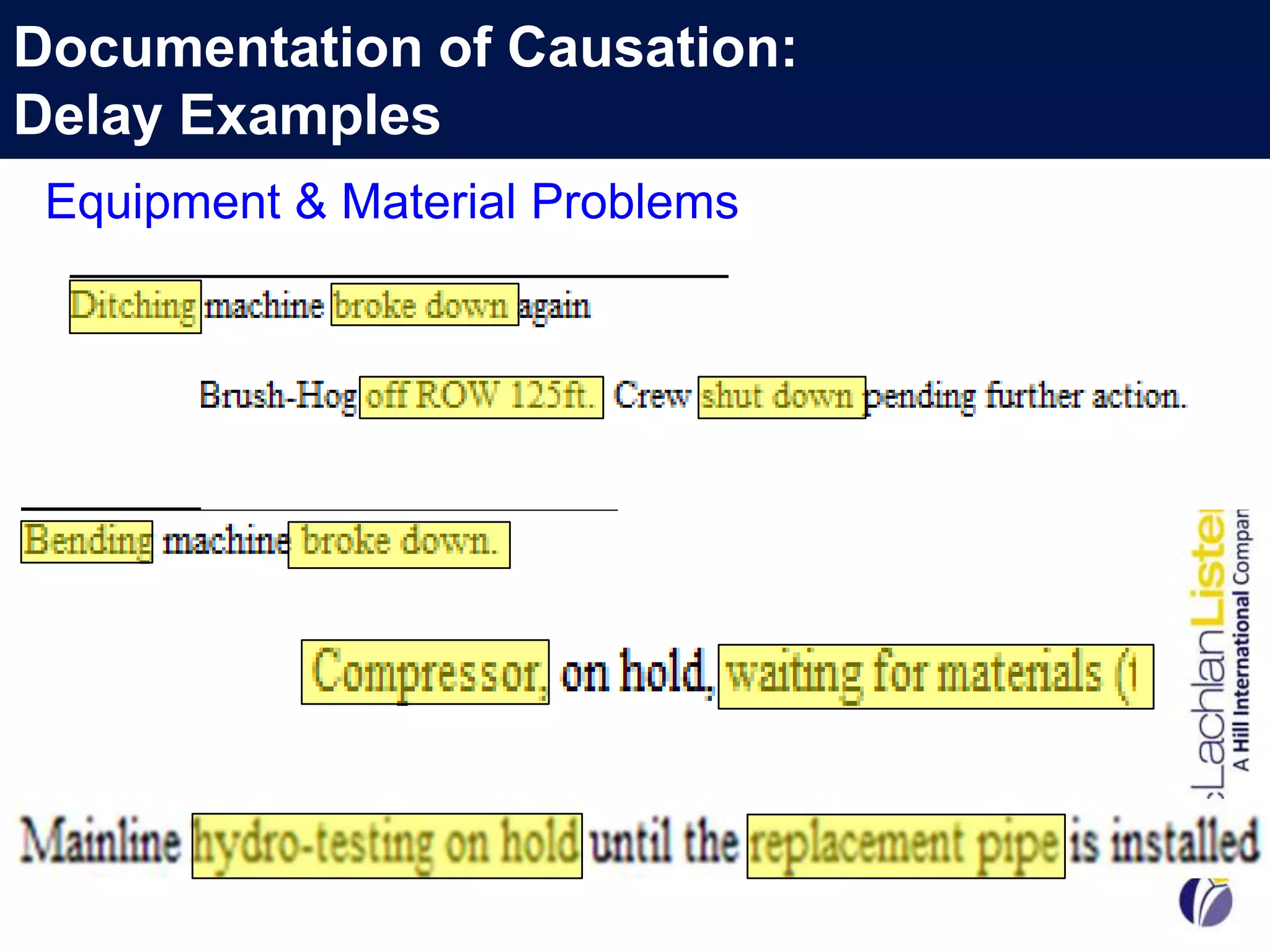

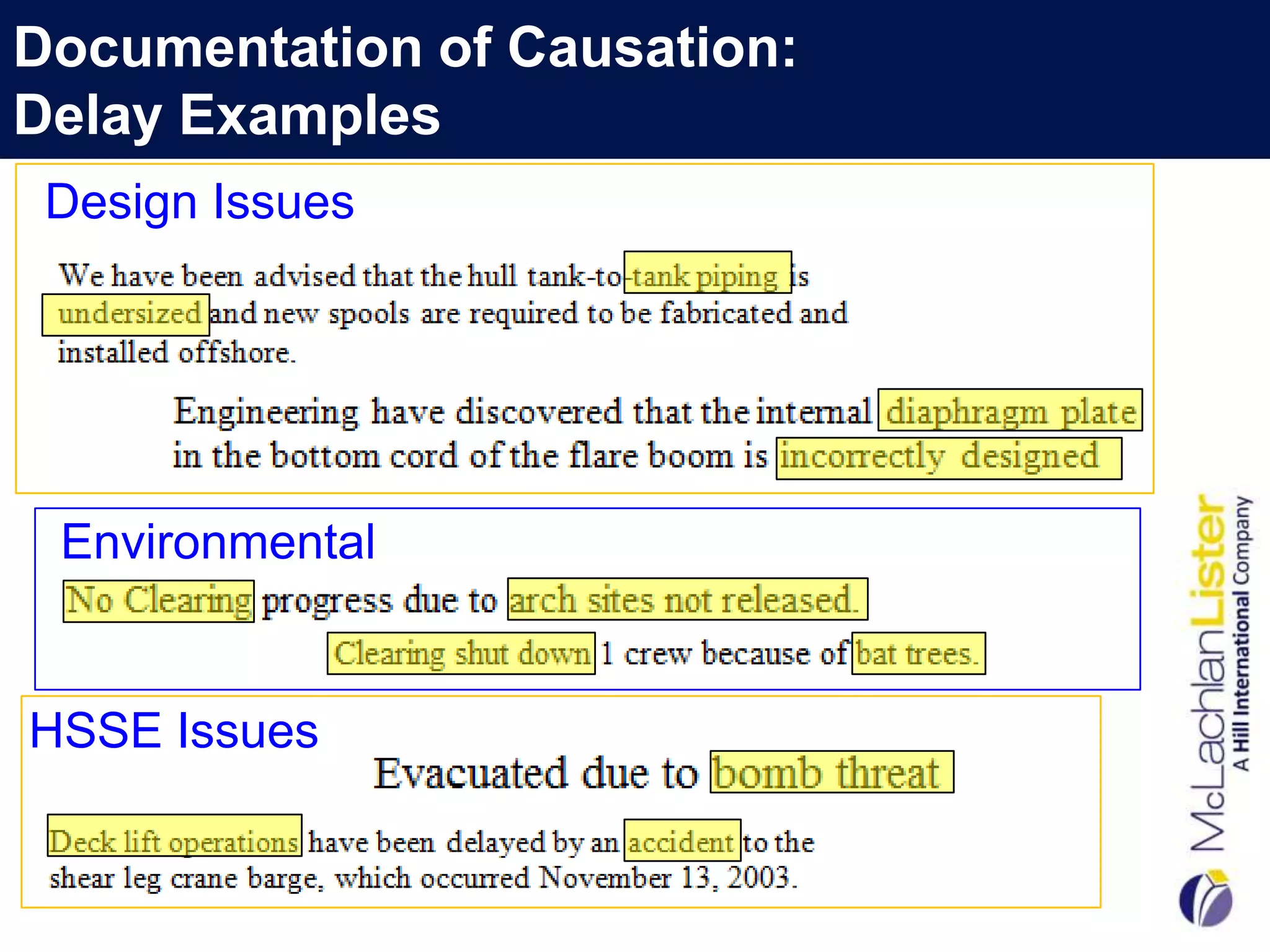

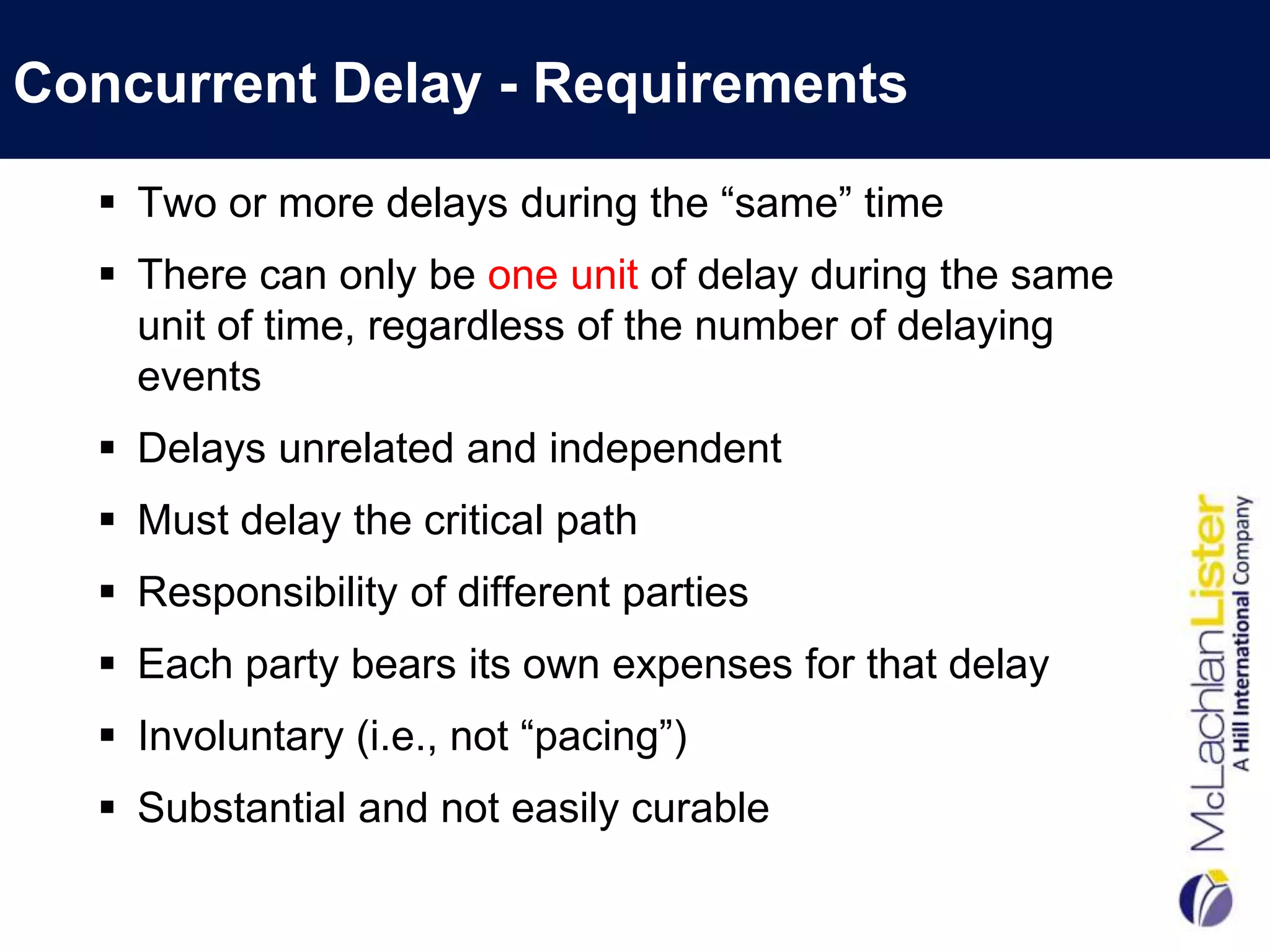

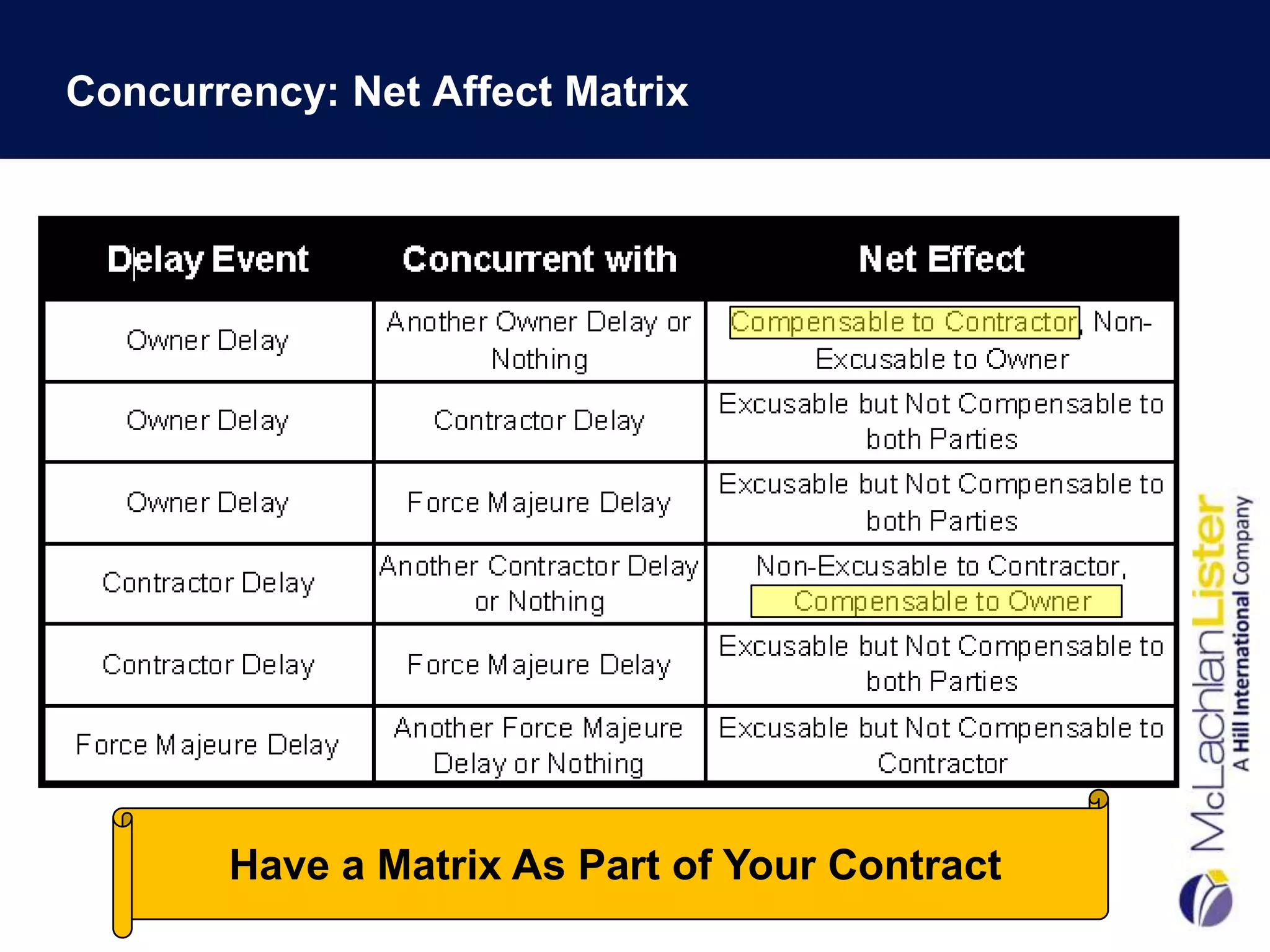

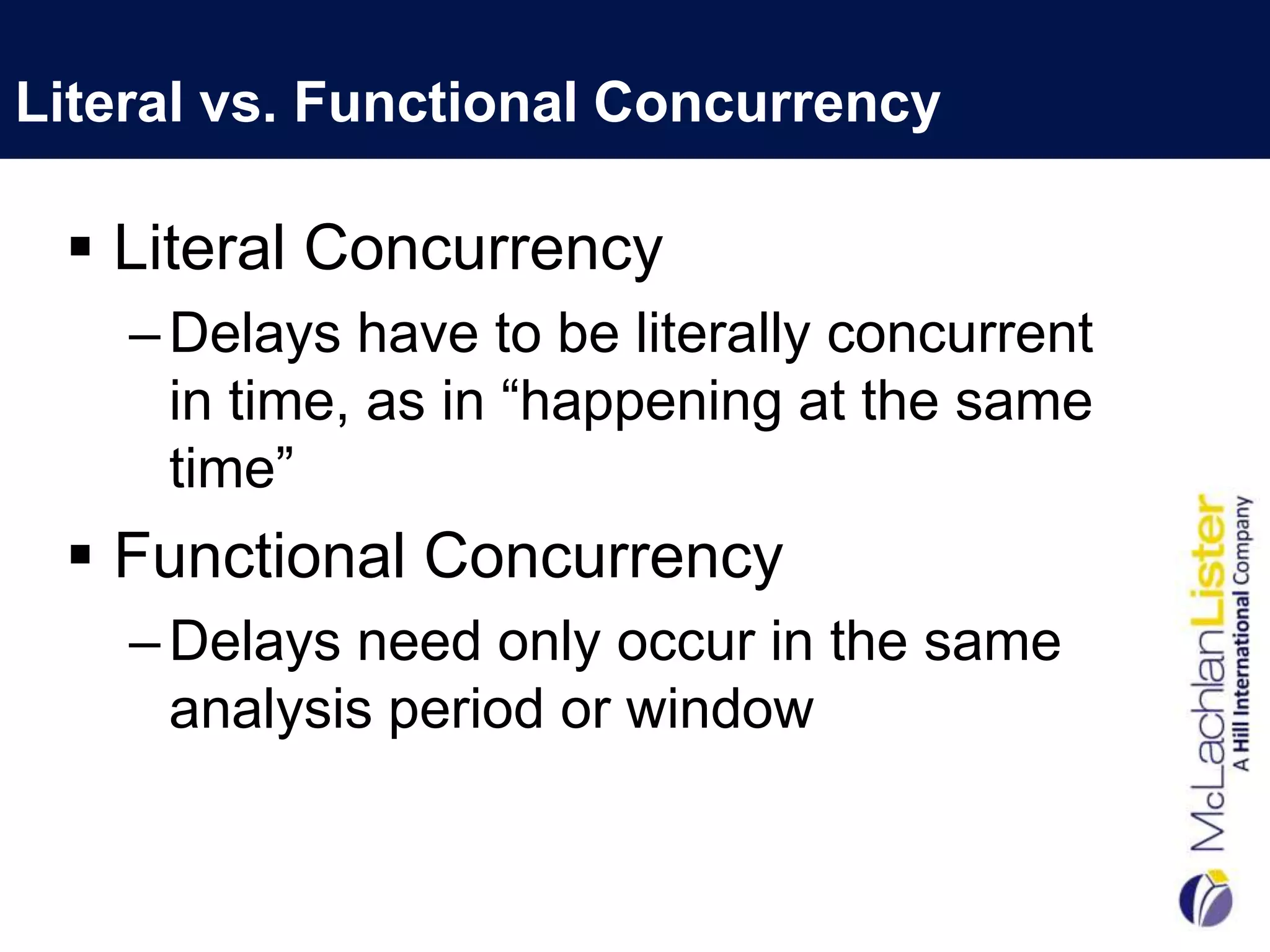

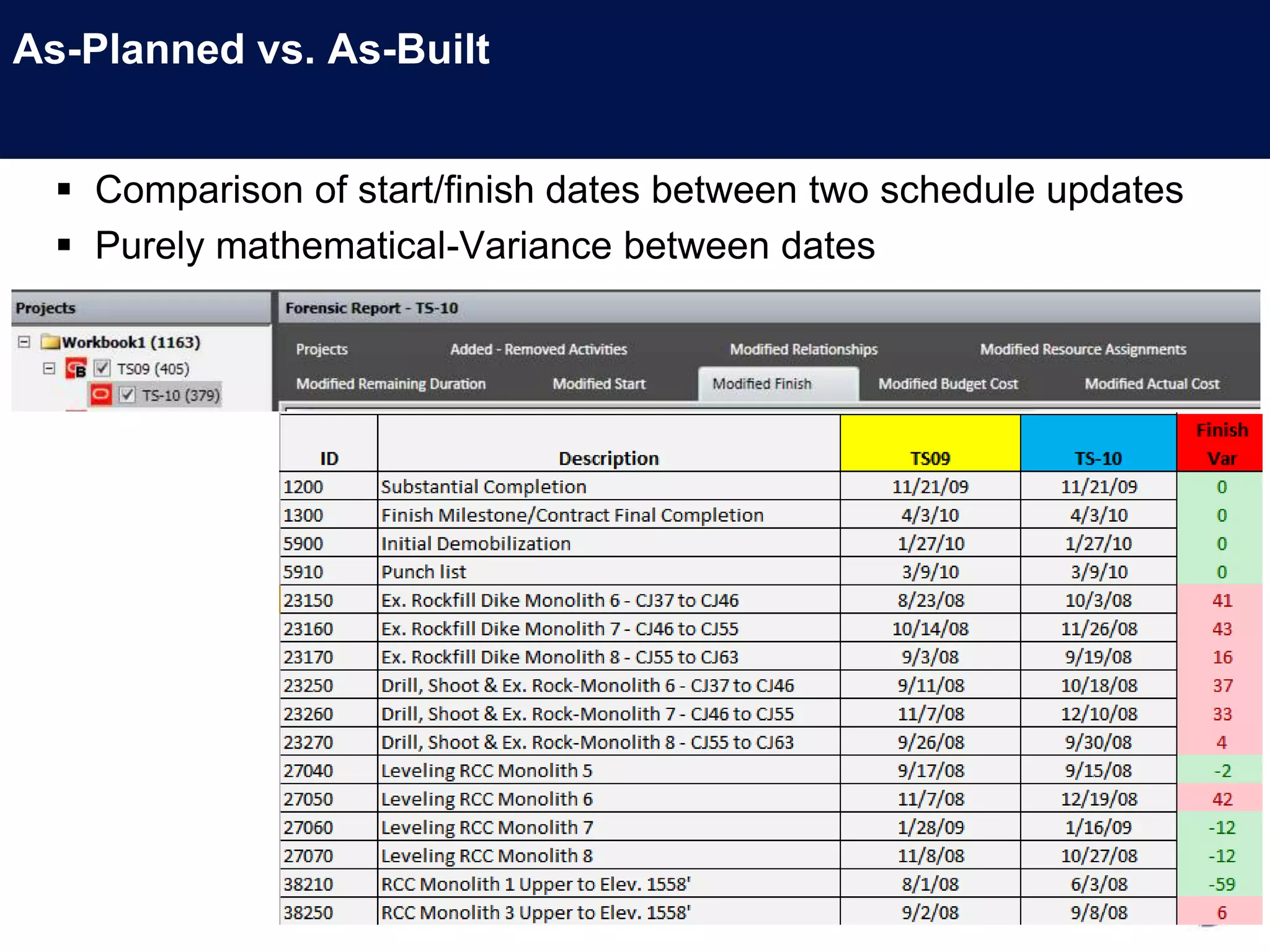

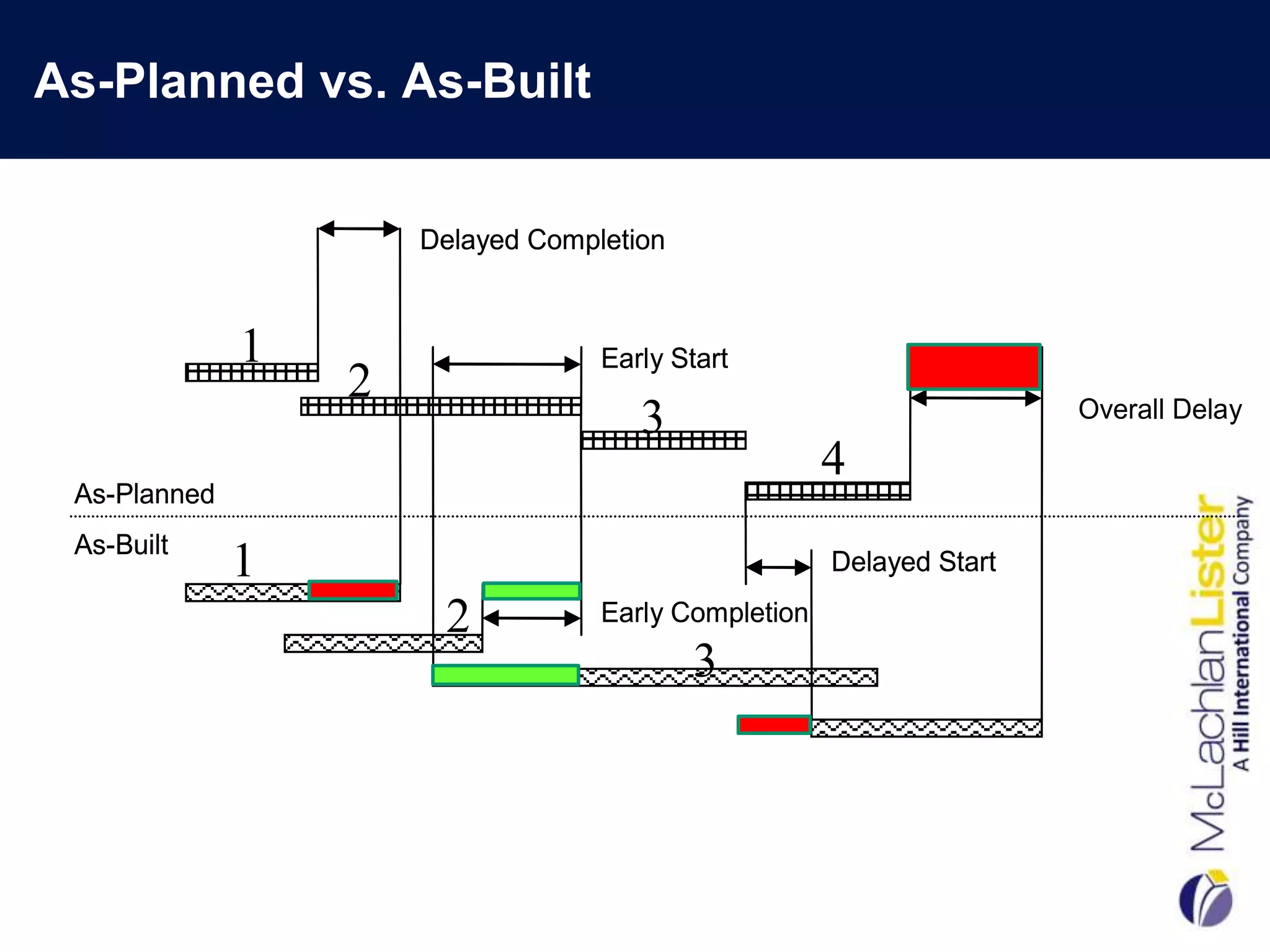

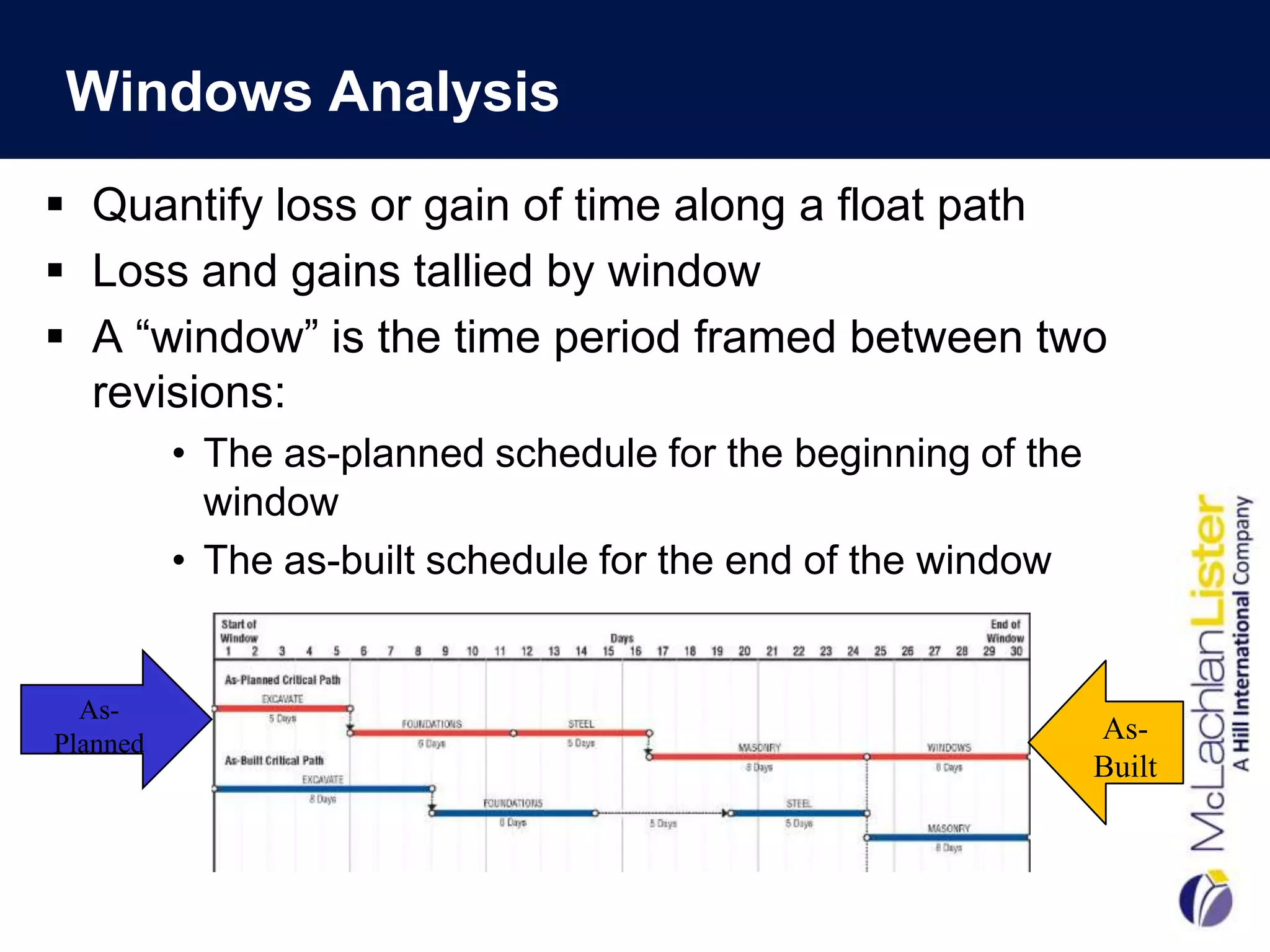

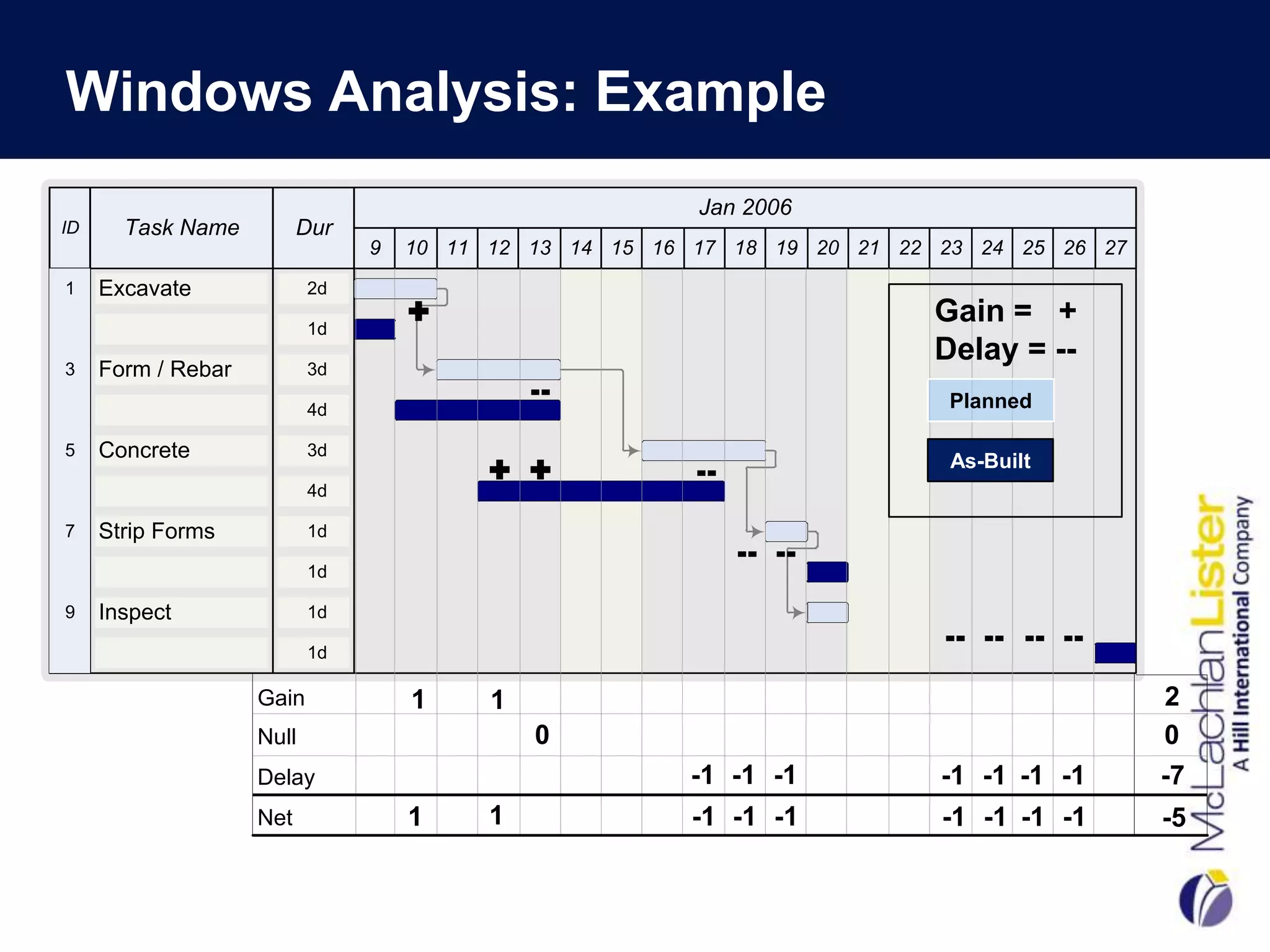

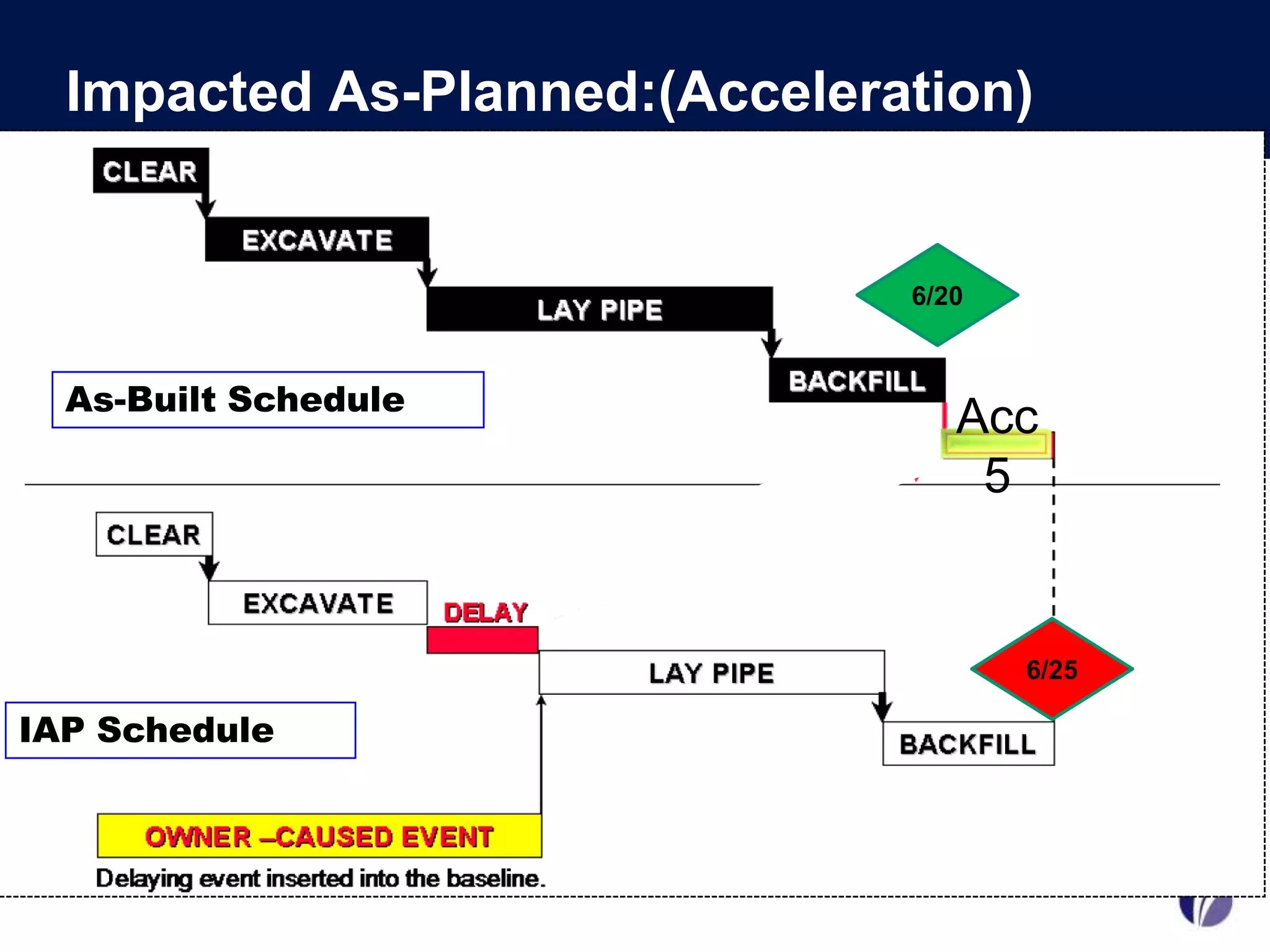

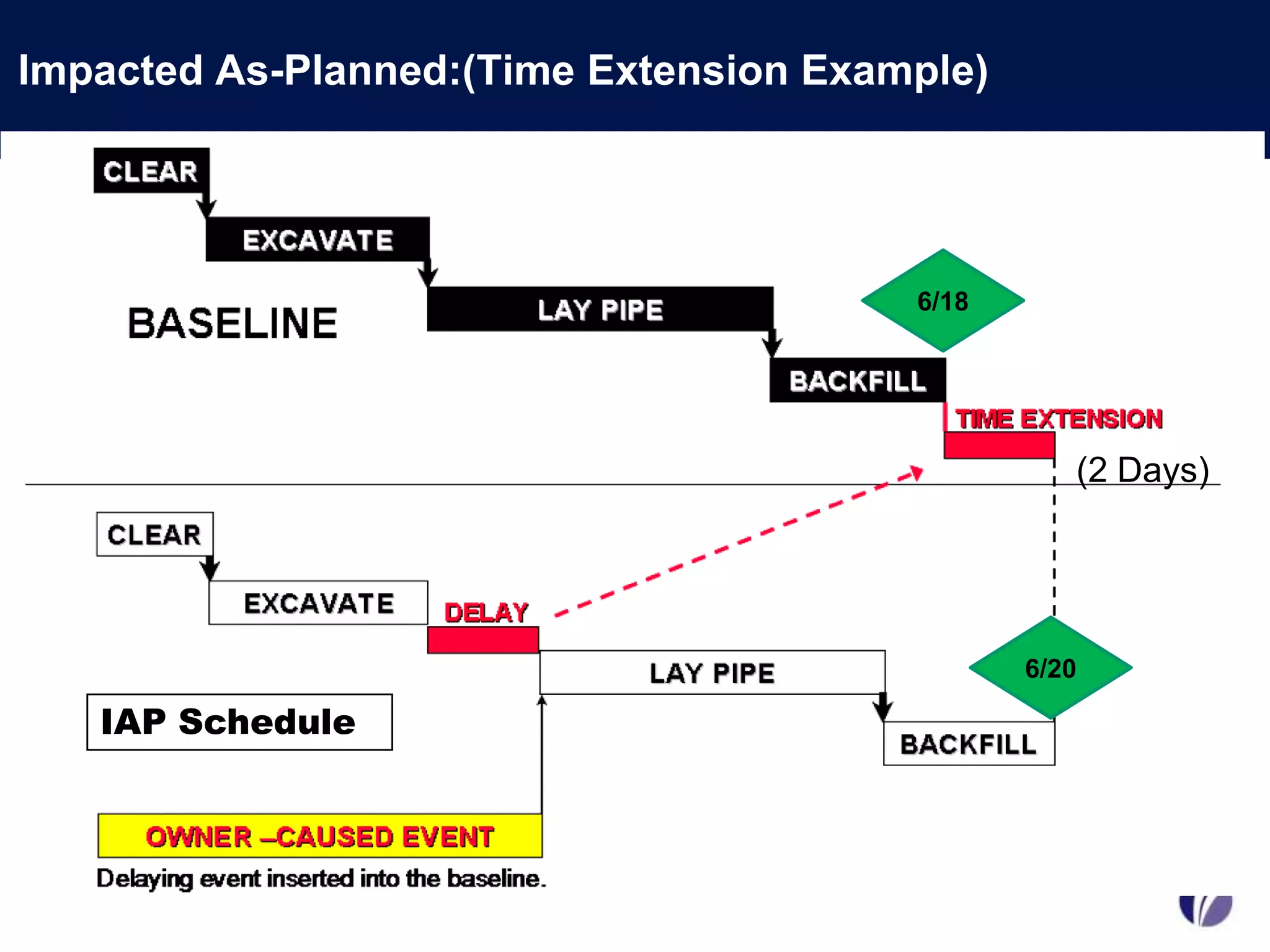

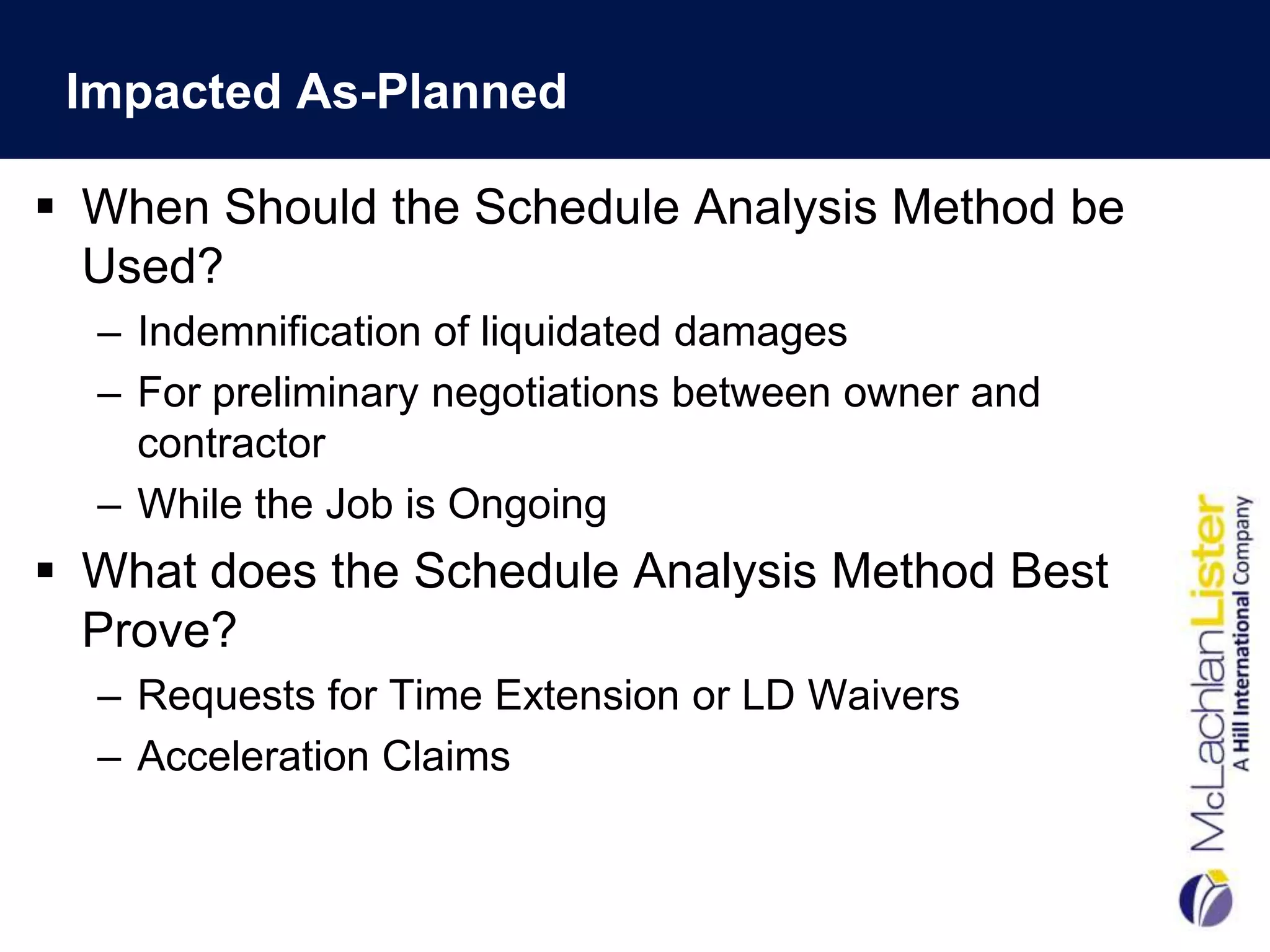

The document outlines the key aspects of determining and managing extensions of time (EOT) in construction projects, focusing on triggering events, schedule integrity, and documentation requirements. It discusses different types of delays, responsibility assignments, and various schedule analysis methods, emphasizing the importance of accurate documentation and sound scheduling practices. The presentation also highlights techniques for effective claims presentation and managing concurrency among delays.