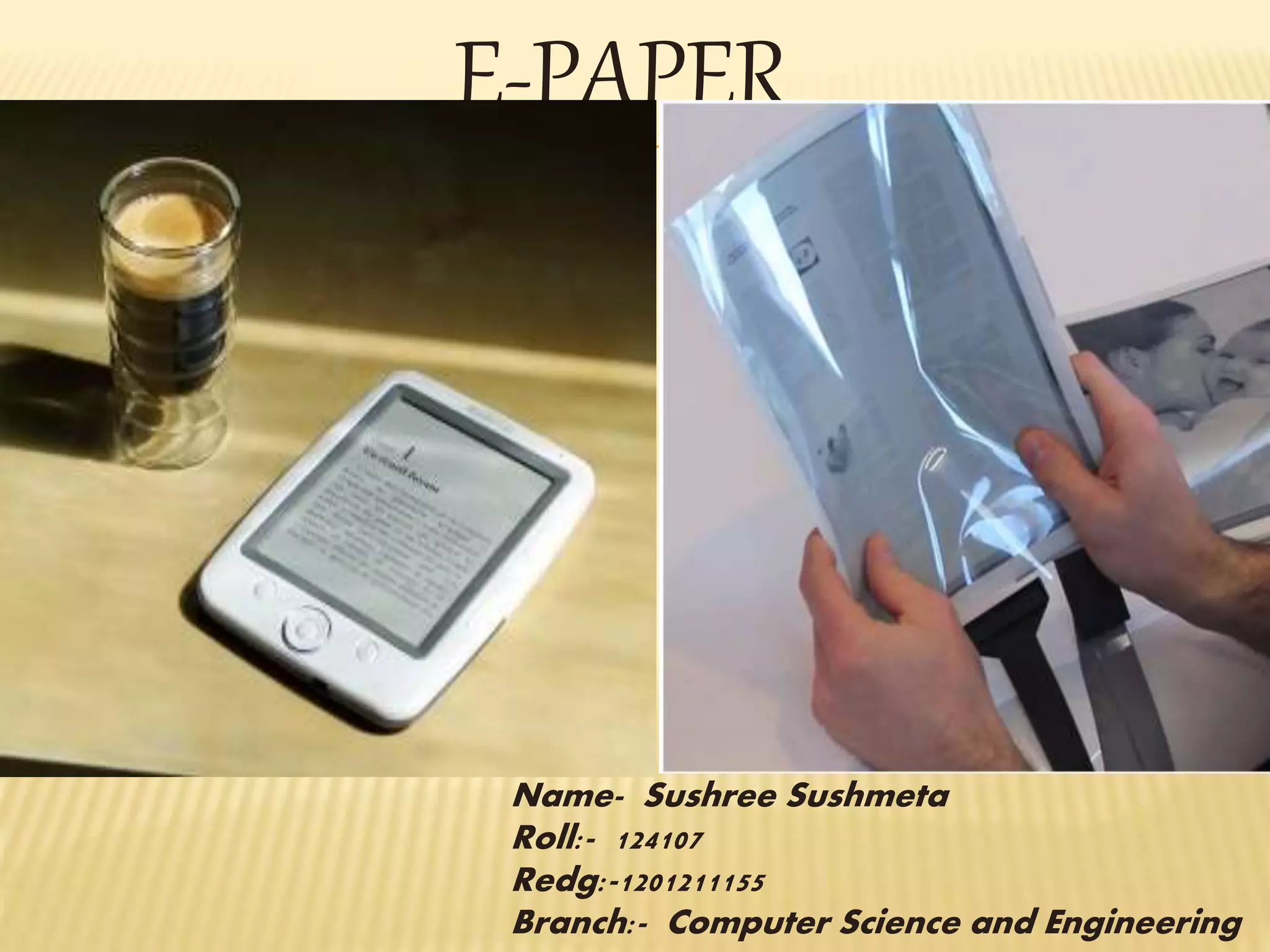

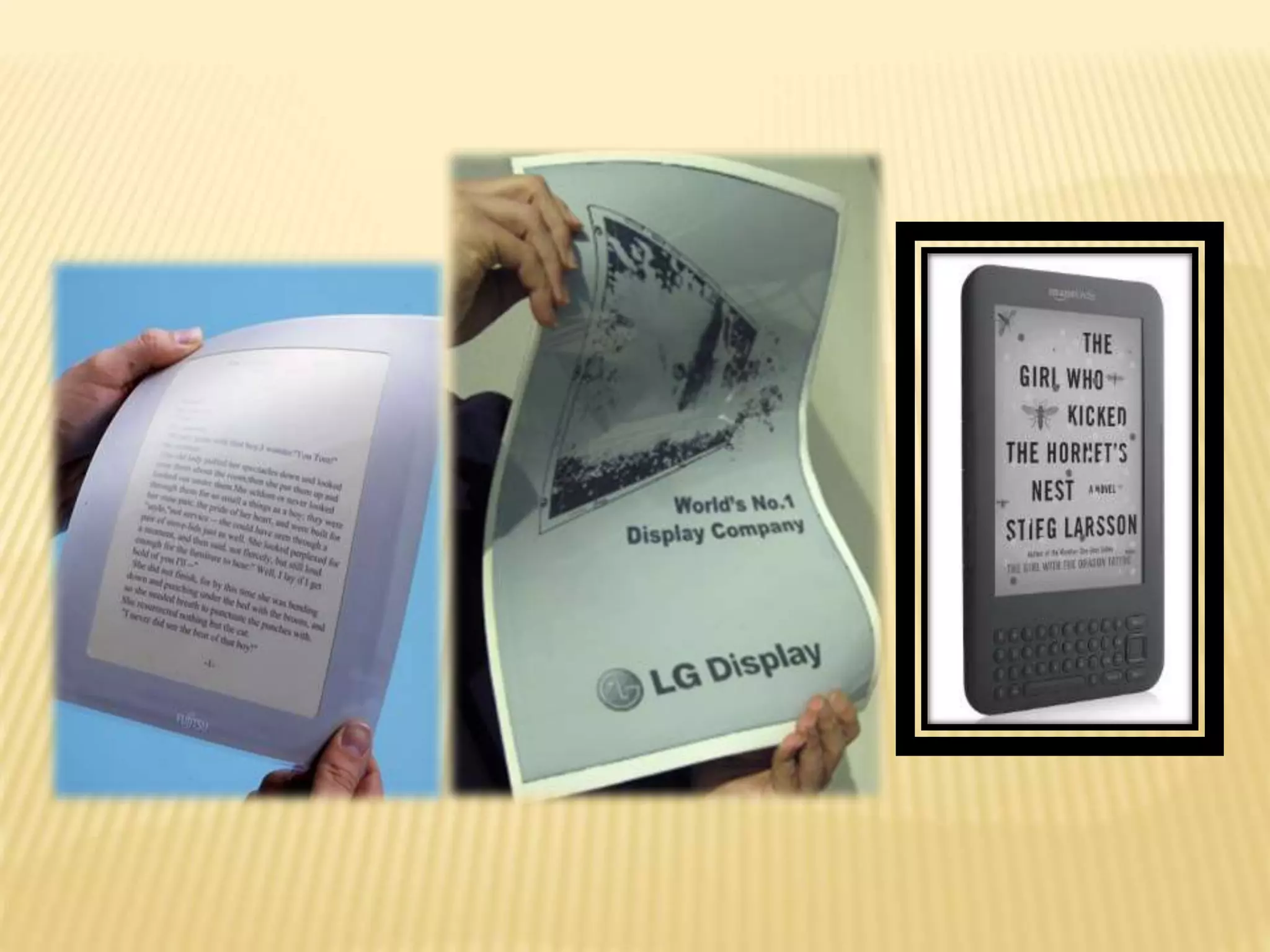

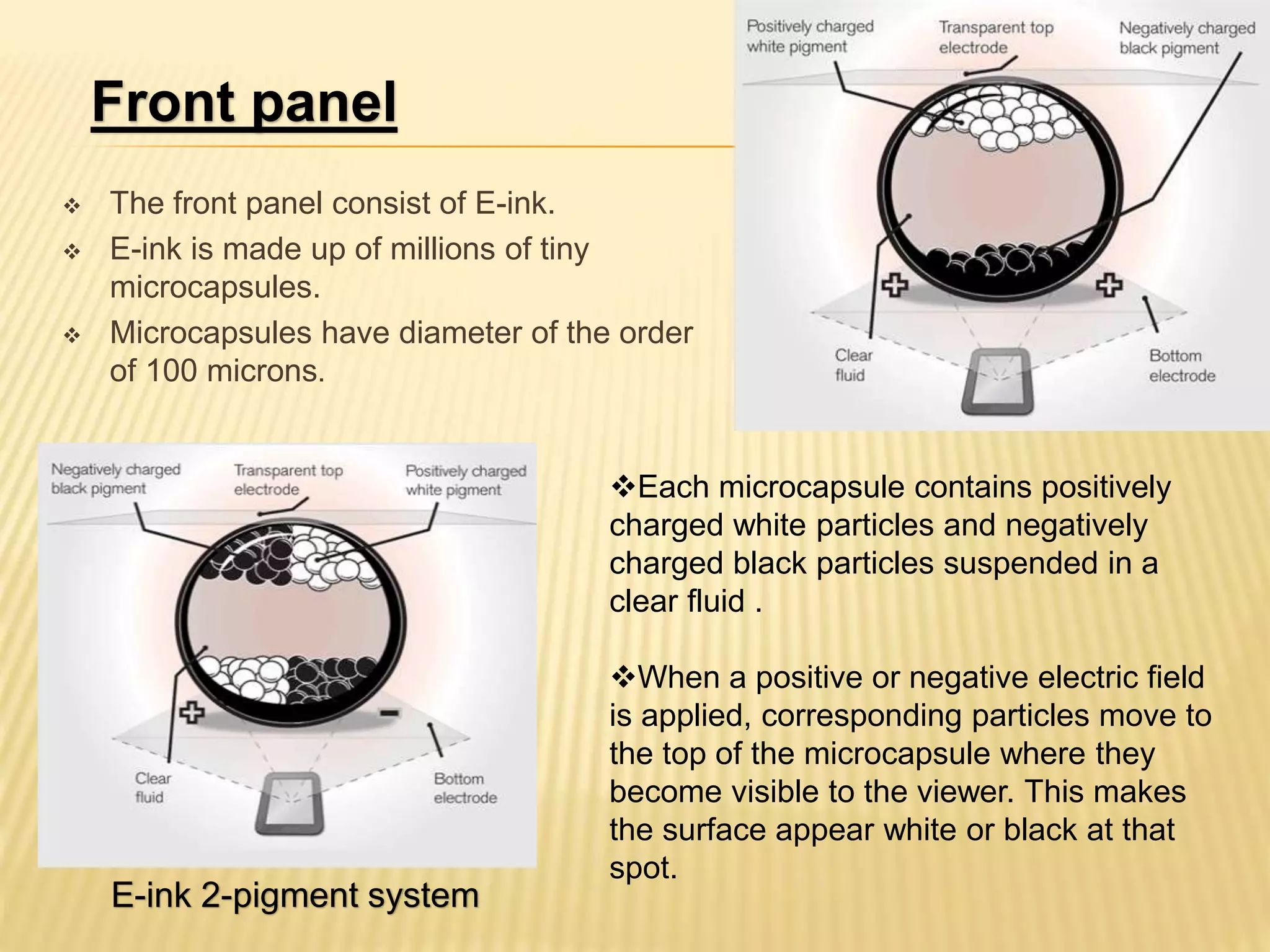

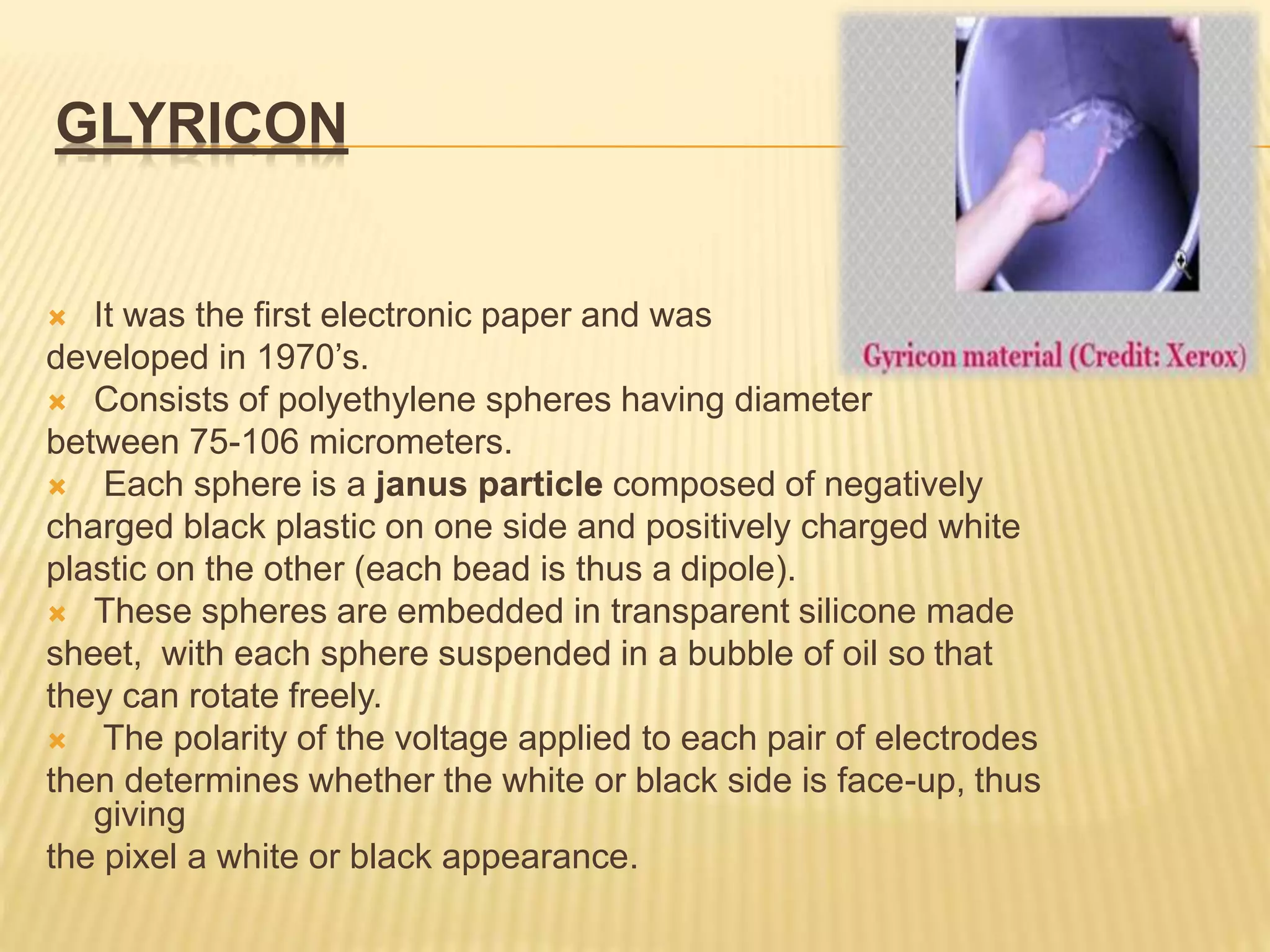

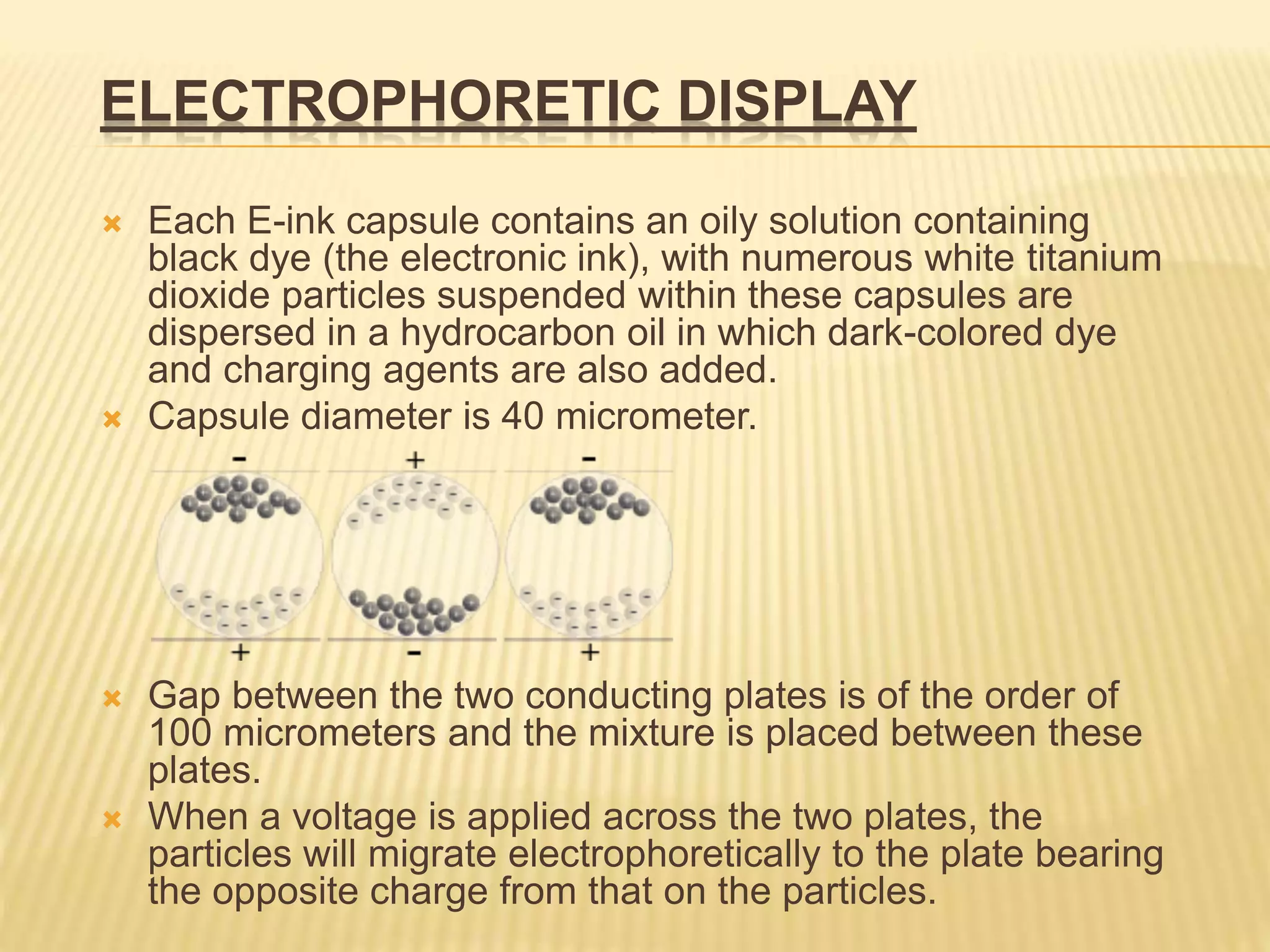

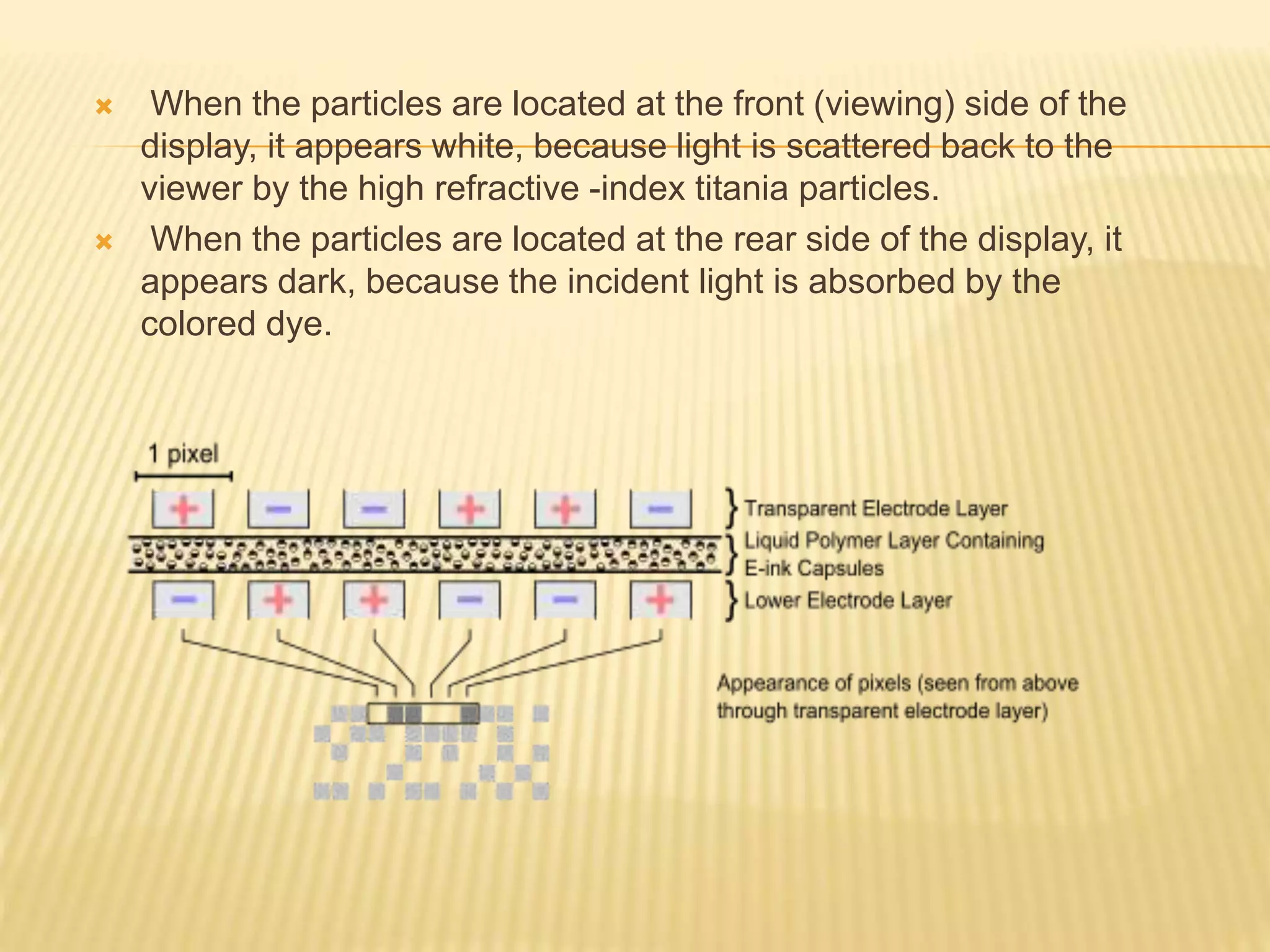

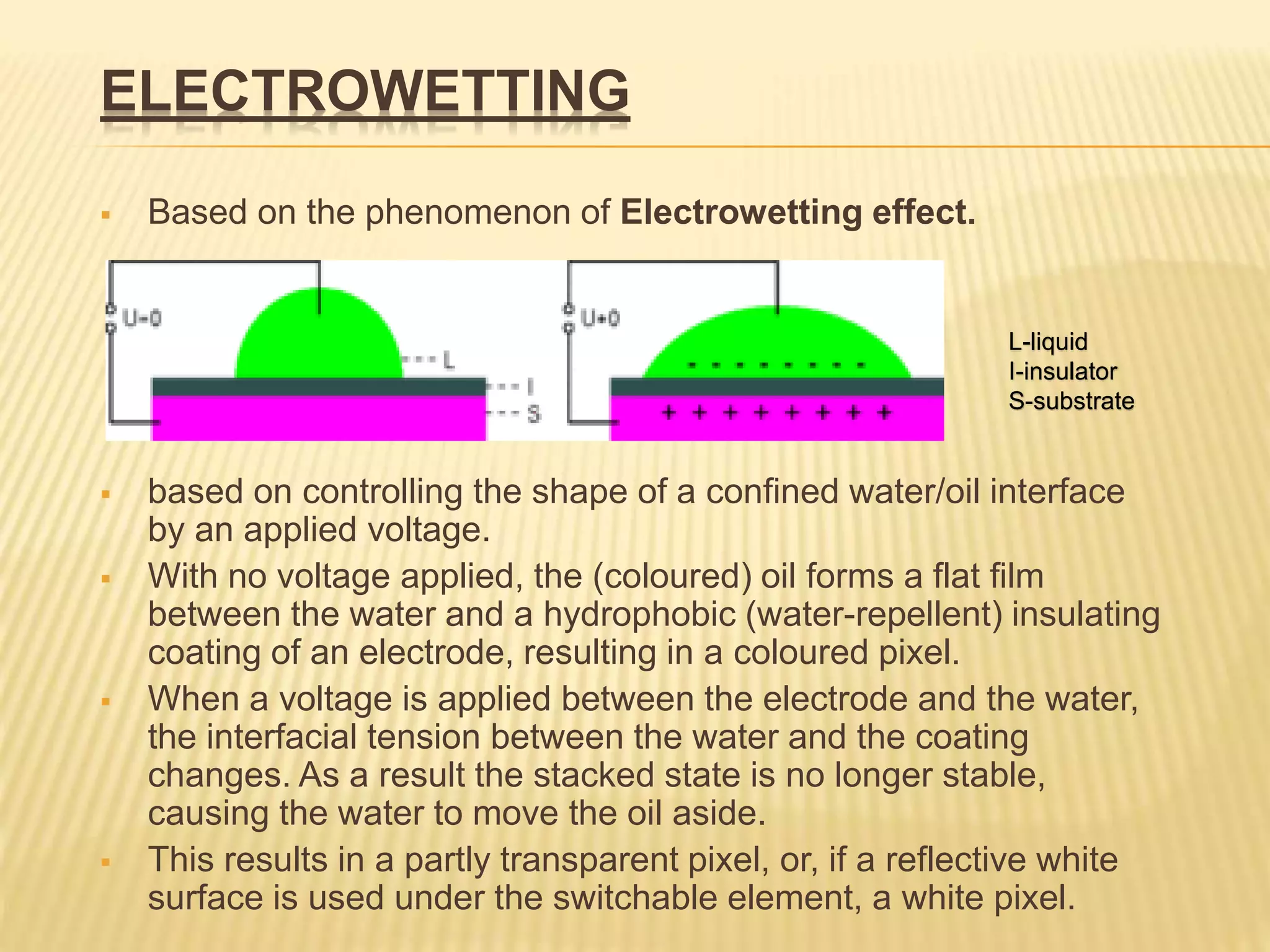

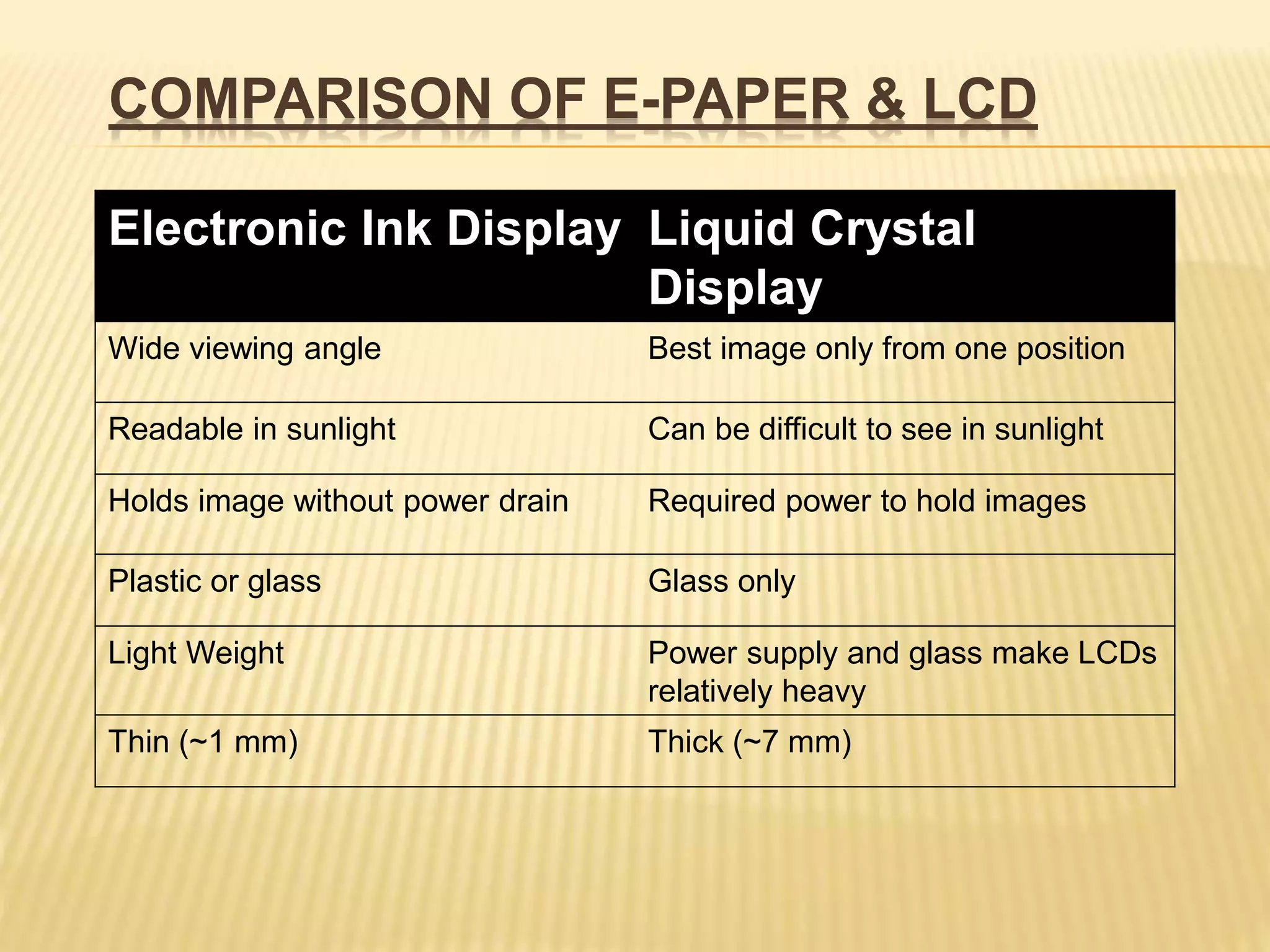

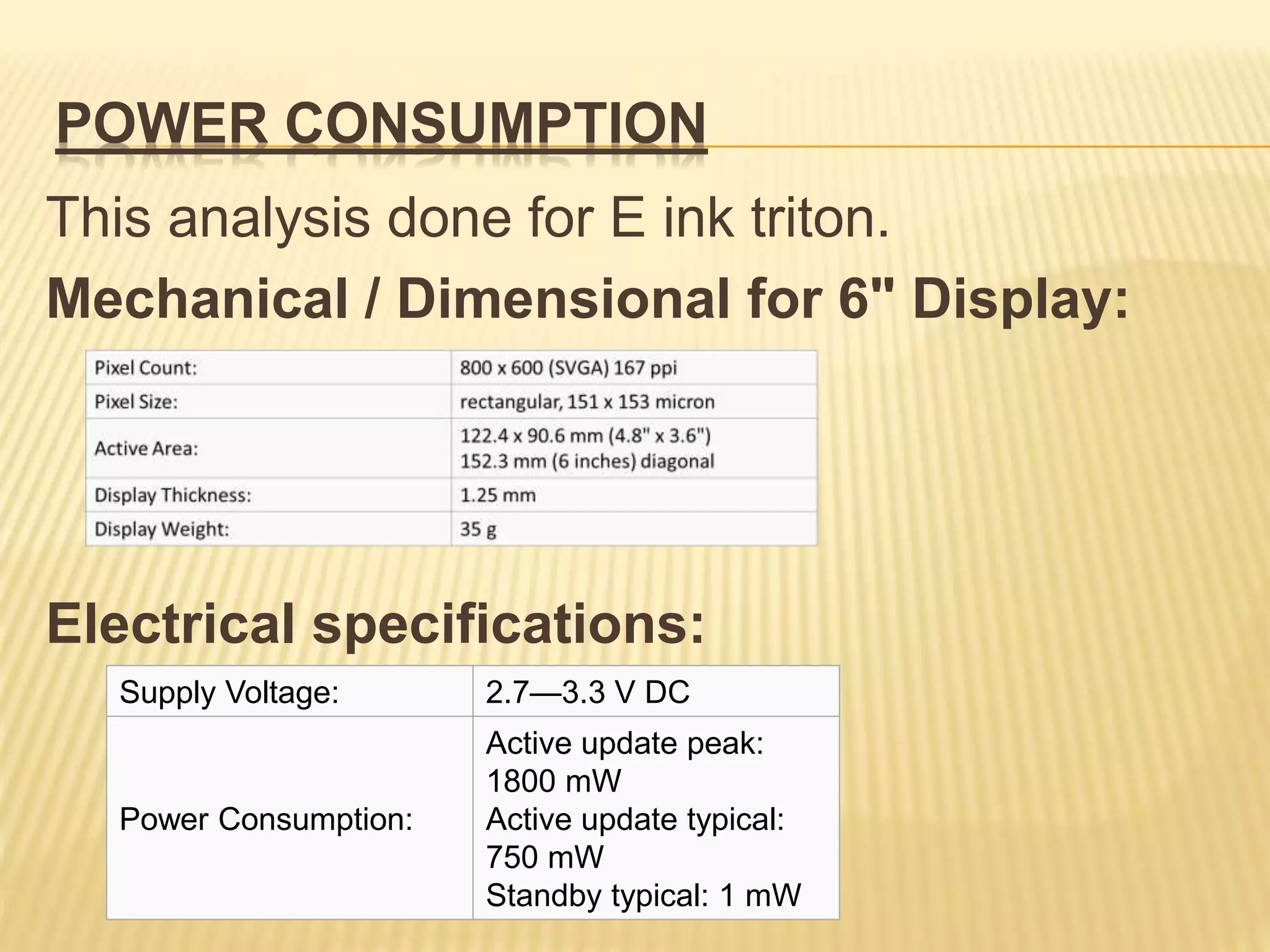

E-paper, also known as electronic paper or electronic ink display, was first developed in the 1970s. It reflects light like ordinary paper and is more comfortable to read than backlit displays. E-paper has a front panel made of e-ink microcapsules containing black and white particles, and a back panel of electronic circuits. It uses very little power and can hold text and images without power, making it suitable for e-book readers and other applications. While e-paper has benefits like a paper-like feel and low power usage, it also has limitations such as slow refresh rates and potential ghosting issues.